There are pros and cons to all sensing technologies, including the latest generation of silicon temperature sensors, as John Austin, of Microchip Technology Inc., explains.

Temperature sensing is the latest addition to the functionality offered by a rapidly expanding list of applications.

This presents designers, across a wide range of products, with the choice of which temperature-sensing technology to use. To do this, they need to weigh up the advantages and disadvantages of new silicon-based temperature sensors as well as the more conventional alternatives of thermocouples, thermistors or Resistive Temperature Detectors (RTDs) for each application.

There is no doubt that silicon temperature sensors are gaining ground and there are good reasons for this: They are simple devices which demand little thermal design expertise but integrate features which give designers the flexibility to add more functions into their products. Other reasons could include their relatively low price-point, the small footprint of the total temperature-sensing solution, and their potential to reduce power consumption compared to the alternative technologies. Then again, perhaps it is the fact that the latest generation of silicon sensors achieves dramatically higher accuracy than previous generations which could tip the balance in favor of using a silicon temperature sensor for the first time. Whatever the reason for considering temperature-sensing with silicon, it is important to fully understand the three distinct types of silicon sensors, logic-, voltage- or serial-output, and the benefits that each type can offer to a particular application.

Voltage-output silicon sensors

The way in which a voltage-output temperature sensor works is similar to a thermistor, which is probably the most widely used device for temperature sensing.

The thermistor’s resistance changes with a corresponding change in temperature. The resistance of a Positive Temperature Coefficient (PTC) thermistor will increase with an increase in temperature, whereas the resistance of a Negative Temperature Coefficient (NTC) thermistor will decrease with an increase in temperature.

In comparison, a voltage-output temperature sensor develops an output voltage which is proportional to the temperature, with a typical temperature coefficient of 6.25 mV/°C, 10 mV/°C or 19.5 mV/°C. Temperature-to-voltage converters can sense a -55°C to +150°C temperature range and feature temperature offset which allows negative temperatures to be read without requiring a negative supply voltage. Typical operating currents are in the tens of microAs, which minimises self-heating and maximises battery life.

Using a thermistor has certain disadvantages, compared to using a voltage-output silicon temperature sensor: The thermistor solution can consume orders of magnitude more power than the latest silicon-based temperature sensors, and the thermistor is nonlinear which results in a restrictive temperature range. Depending upon the temperature range of the application, the thermistor solution may also need external circuitry which can add to both the board space and overall cost.

In comparison, silicon-based solutions are very linear over a temperature range of -55°C to +150°C, and offer solutions down to an SC70 package. Overall, therefore, the silicon solution can offer a smaller, lower cost, and more power-efficient solution compared to a thermistor.

Logic-output silicon sensors

Logic-output temperature sensors typically function like a thermostat, notifying the system when a minimum or maximum temperature limit has been reached. Sometimes referred to as temperature switches, they can be used to turn-on a fan or a warning light, when high- or low-temperature conditions are detected. As the output is typically not latched, the switch will turn off when the temperature falls below or rises above the temperature set point. Most logic-output sensors have an integrated hysteresis of a few degrees Celsius to prevent output chatter.

With a thermistor, one way to implement this is to add a comparator circuit. This, however, would add errors to the system, such as offset and offset drift from the comparator, which would need to be resolved by accommodating the mismatching of any resistors used in the circuit and performing a single temperature trim to calibrate the circuit.

A silicon-based solution would be much simpler to implement as all of the trimming and calibration is carried out by the manufacturer.

Serial-output silicon sensors

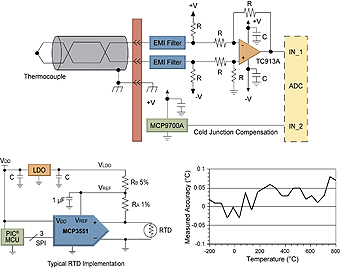

The most common way to achieve highly accurate and very repeatable temperature measurements has typically been to use either thermocouples or Resistive Temperature Detector (RTD) circuits. However, as Figure 1 demonstrates, both of these solutions can develop into large, expensive and complex circuits in order to achieve high temperature accuracy or high measurement resolution.

In silicon temperature sensing, it is the serial-output sensors which achieve the highest accuracy, integration and flexibility whilst retaining the inherent simplicity of a silicon solution. Serial-output sensors use a two- or three-wire interface to the host microcontroller and typically integrate an onboard Analogue-to-Digital Converter (ADC) that converts the analogue output of the internal sensing element to a digital output. One example of a serial-output temperature sensor is the Microchip MCP9804, shown in Figure 2. This high-accuracy, high-integration digital temperature sensor achieves typical temperature accuracy of 0.25°C and user-selectable measurement resolution of between 0.5˚C to 0.0625˚C within a tiny 2 mm × 3 mm DFN package.

Many serial-output temperature sensors also integrate other user-programmable functions, such as over- and under-temperature alerts and onboard EEPROM. These features can be used to simplify a design, increase its flexibility, improve temperature-sensing accuracy and lower overall system cost.

The most common limitation of serial-output temperature sensors, compared to RTD and thermocouples, is their operating temperature range. Silicon temperature sensors are generally specified to operate from -55°C to +150°C, whereas RTDs and thermocouples can provide an accurate solution over a few hundred, or a couple of thousand, degrees Celsius, respectively.

Conclusion

There are advantages and disadvantages with all temperature sensing technologies and no single technology is appropriate for all temperature-sensing applications.

For applications that operate over a limited temperature range, thermistors can provide a useful, low-cost temperature-sensing solution. For high accuracy over several 100s of degrees Celsius, then RTDs can be a sensible choice but require careful scaling and calibration and can be more costly than thermistors or silicon-sensor solutions. Whilst for measuring extreme temperatures, thermocouples are likely to be a leading contender. However, for the vast number of applications which do not need to measure a very wide range of temperatures, silicon-based sensors can significantly simplify the design, maintain accuracy and integrate functions which increase system flexibility and

performance.

www.microchip.com