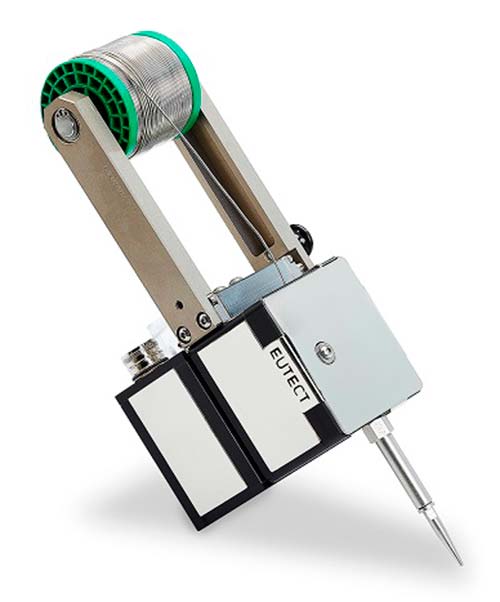

Eutect GmbH further developed and optimized its Sensitive Wire Feeder (SWF). The world’s only patented intelligent wire feeder can be used in conjunction with a laser, iron or induction system for soldering assemblies. As part of its continuous product development, the Swabian soldering specialist is now presenting a new development version of the successful product.

Eutect GmbH further developed and optimized its Sensitive Wire Feeder (SWF). The world’s only patented intelligent wire feeder can be used in conjunction with a laser, iron or induction system for soldering assemblies. As part of its continuous product development, the Swabian soldering specialist is now presenting a new development version of the successful product.

“The SWF is one of our best-selling modules. Not only do we use the SWF in our special soldering systems for the electronics industry, but we are also increasingly selling the module itself to other assembly system providers, for integration into their systems,” explains Matthias Fehrenbach, Managing Director of Eutect GmbH, and continues, “For this reason, we are continuously optimizing the SWF. The current adjustments include a number of measures that once again raise the SWF to a new level.”

For one thing, the drive of the SWF is now shielded by a metal cover, which improved EMC compatibility. Furthermore, a new signal filter software has been added to the module. Thanks to these measures, the new generation of the SWF achieves even more precise measuring accuracy and stability during wire feed. In addition, the weight of the overall module has been reduced by 11%, allowing the SWF to be moved more dynamically when integrated on a robot arm. “We can thus further optimize cycle times. The overall design reduces the time required for the robot arm to settle, which also allows us to use a less expensive robot for select projects,” Fehrenbach elaborates.

Another adaptation optimizes integration in robot applications. For example, the metal spool that guides the wire from the wire roll dispenser to the SWF has been replaced by a tube of lower weight, which means that the wire roll can now be integrated very flexibly in the production cell. Thus, maximum flexibility as well as a reduction of the required space are achieved. The flexible mounting of the solder wire roll results in a weight saving of up to 1.3 kg when using a full reel, which corresponds to a reduction of approx. 50% compared to the previous weight.

Service and changeover friendliness were also taken into account in the optimization measures. For example, the sheet metal covers of the wire feeder housing can be removed without tools. The covers can now be removed easily and simply, as they are held in place by a magnetic mechanism without screws. It also is easier now to change between different wire diameters. Using simple sheet metal covers allows better accessibility of the diameter setting on the control wheel and encoder wheel swing arm. New and more variable SWF configurations, as well as the use of solenoids or spring packs, and a wire insertion aid supported and controlled by the force sensor also assist the operator. By pressing on the drive housing of the SWF, the wire is automatically fed, or retracted, without the operator having to execute a command within the software via the HMI. Simply by selecting the wire change via the HMI, the module enters that mode, allowing for a quick and easy changeover. “This allows us to save valuable time,” says Fehrenbach.