Greater yields, less routine work for the operators on the shop floor: WORKS Process Expert from ASMPT, the world’s first self-learning in line expert system for electronics production, reduces scrap and operator assists along the entire SMT line. The latest version of the process-optimizing software now also includes the placement process in addition to solder paste printing and even works with SPI and AOI systems from other manufacturers.

Greater yields, less routine work for the operators on the shop floor: WORKS Process Expert from ASMPT, the world’s first self-learning in line expert system for electronics production, reduces scrap and operator assists along the entire SMT line. The latest version of the process-optimizing software now also includes the placement process in addition to solder paste printing and even works with SPI and AOI systems from other manufacturers.

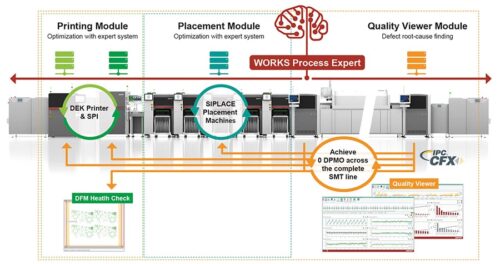

SMT lines learn and optimize themselves: Together with the DEK printing platform, the high-speed Process Lens SPI system and the SIPLACE placement machines from ASMPT, the WORKS Process Expert software forms a self-learning inline expert system that lets electronics manufacturers produce faster, more cost-effectively, and with significantly higher yield. While autonomous process control was previously limited to solder paste printing, the new version of WORKS Process Expert in combination with end-of-line AOI systems now also supports the optimization of the placement process by driving the operators to the tasks with the highest positive impact on the process. With its connection to SPI and AOI systems, it supports process and quality engineers in identifying the defect root-cause across the complete SMT line, thus ensuring its elimination and higher yield.

Following its Open Automation principle, the SMT specialist has also opened up the trend-setting software to third-party equipment, allowing WORKS Process Expert to process data from SPI and AOI systems made by other manufacturers. Seamless connectivity of the inspection solutions in the SMT line is ensured by the open IIoT and communication standard IPC-CFX. The smart software thus becomes a powerful solution for higher yields and better quality while simultaneously reducing operator assists along the entire SMT line, making it a significant contributor to the realization of the integrated smart factory.

Following its Open Automation principle, the SMT specialist has also opened up the trend-setting software to third-party equipment, allowing WORKS Process Expert to process data from SPI and AOI systems made by other manufacturers. Seamless connectivity of the inspection solutions in the SMT line is ensured by the open IIoT and communication standard IPC-CFX. The smart software thus becomes a powerful solution for higher yields and better quality while simultaneously reducing operator assists along the entire SMT line, making it a significant contributor to the realization of the integrated smart factory.

“Hardware and software for industrial inspection solutions are available from many manufacturers,” says Jérôme Rousval, Product Manager Process Solutions at ASMPT, “but hardly anyone has such a wealth of experience and comprehensive process knowledge as ASMPT. Since we cover the entire electronics manufacturing process chain with our hardware and software as well as with our automation solutions, we are also one step ahead when it comes to process automation. And this is especially beneficial for our customers’ employees.”

Online show: Facts on Open Automation

Providing the best possible support for operators with intelligent software and smart process optimization is also the subject of the next installment of the ‘Facts on Open Automation’ show on Wednesday April 26, 2023. “Where in the past several operators used to be responsible for a single SMT line, today often only one operator remains,” explains host Laszlo Sereny. “He or she must keep the entire line running, replace stencils in the solder paste printer according to customer specifications, and ensure timely material replenishments at the placement machines – all while keeping an eye on the key performance indicators at all times. Multitasking and process know-how are in demand, and emergency operations are not uncommon.” Sereny and his studio guests will discuss how software supports operators during assists based on their qualifications and the respective task priorities, and how autonomous process control solutions help with quality assurance. Axel Lindloff, Senior Process Specialist at Koh Young, will join them remotely.

More information about ‘Facts on Open Automation’:https://facts-on-open-automation.smt.asmpt.events/