Industrial sensors continue to get smaller and smarter while the environments in which they operate continue to grow bigger and more demanding. With thousands of pieces of equipment operating in close proximity to one another, their power supplies quickly become cross-contaminated. As a result, the regulated voltage levels may only bear a vague resemblance to their nominal values. In this design solution, we review the challenges faced by sensors operating in an industrial environment, common mitigation solutions, and their limitations. We then propose a simpler solution which provides increased robustness and reliability in a smaller area.

Industrial sensors continue to get smaller and smarter while the environments in which they operate continue to grow bigger and more demanding. With thousands of pieces of equipment operating in close proximity to one another, their power supplies quickly become cross-contaminated. As a result, the regulated voltage levels may only bear a vague resemblance to their nominal values. In this design solution, we review the challenges faced by sensors operating in an industrial environment, common mitigation solutions, and their limitations. We then propose a simpler solution which provides increased robustness and reliability in a smaller area.

The Sensor Environment

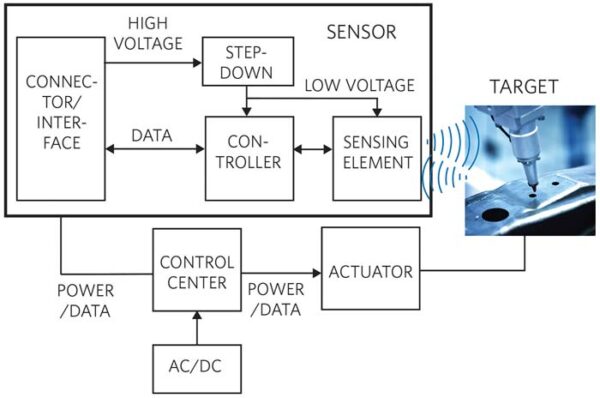

Industrial sensors are used to monitor the status of a quantity of interest in an industrial process. For example, Figure 1 shows a proximity sensor being used to detect movement of raw material on a production line. Examples of other quantities measured using sensors include temperature and pressure.

Sensors may be located anywhere on the factory floor. They are either analog or digital in nature and typically receive power from an isolated 24Vdc voltage source. A controller (typically a PLC) receives information from a sensor through digital or analog I/O modules and sends an appropriate instruction to an actuator via a fieldbus. Many modern sensors include an IO-Link® interface which allows the status of the sensor to be continually monitored, helping to improve factory throughput and enable adaptive manufacturing. IO-Link allows decisions to be made at the sensor level, eliminating the need to wait on the PLC. Figure 2 shows a typical industrial sensor system.

The interface handles data transfer and routes the 24Vdc power to a step-down voltage regulator. The regulator delivers either 5V or 3.3V to the microcontroller and to the sensing element. However, the 24V to 5V/3.3V down-conversion is a step that can be costly in terms of power loss and space occupancy and may require lengthy custom design. In addition, the factory floor can be a very challenging environment, with long cables and strong electromagnetic interference resulting in high-voltage transients. Accordingly, the step-down converter inside the sensor must be able to withstand voltage transients that are much higher than the sensor operating voltage (up to 50V).

Traditional LDO Solution

If sensor current consumption is small, then an LDO solution is often considered for its benefits of small size and ease of design. However, this solution is very dissipative at only 21% efficiency (5V/24V). If the current is high, as with modern sensors (which typically consume currents of 10mA or higher), then this solution requires a bulky heatsink, and the LDO’s size advantage disappears.

Switcher Solution

The most common alternative to the LDO is to use a high-efficiency switching regulator such as a buck regulator IC with discrete inductors, capacitors, and resistors. These have the advantage of much higher efficiency and consequently less heat dissipation – which becomes ever more important as sensors pack more functionality into ever shrinking enclosures. However, these can require knowledge-intensive, time-consuming custom designs along with careful PCB layout to minimize space.

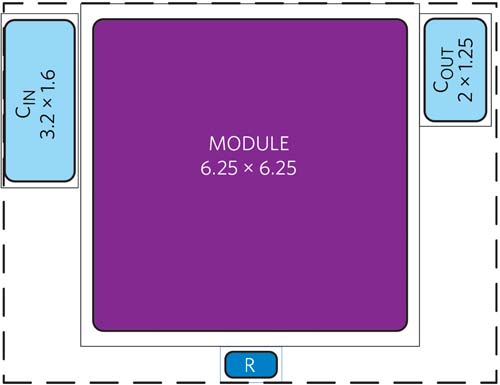

More recently, regulator “modules,” which house the buck converter IC and the inductor in a single package, have become available. Figure 3 shows the component layout for a typical solution of this type (with a total component area of 47.2 mm2).

This module will operate up to a maximum of 40Vdc input. While this may appear to provide a significant margin over the nominal 24Vdc power supply, it will not function if a transient voltage exceeding this voltage occurs. A TVS diode is commonly used to protect an IC against transient surge voltages, however it is not an appropriate choice in this case. To allow the regulator to function unhindered at its maximum operating voltage (40V), the reverse breakdown voltage of the TVS must be close to this value.

One such TVS meets this criteria (SMAJ33A). However, its maximum clamping voltage is 53V, which may be reached in the event of a high energy surge. With a surge at this voltage, the regulator will no longer work and could potentially be damaged.

Higher Voltage Margin

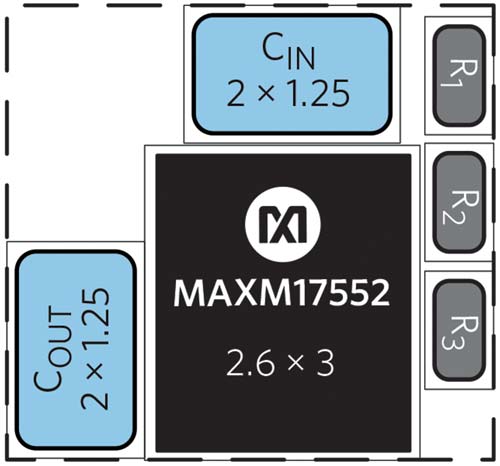

For a sensor to be protected in the presence of surge voltages up to 50V it clearly requires a voltage regulator that will function up to this level. Figure 4 shows a solution that meets this criterion.

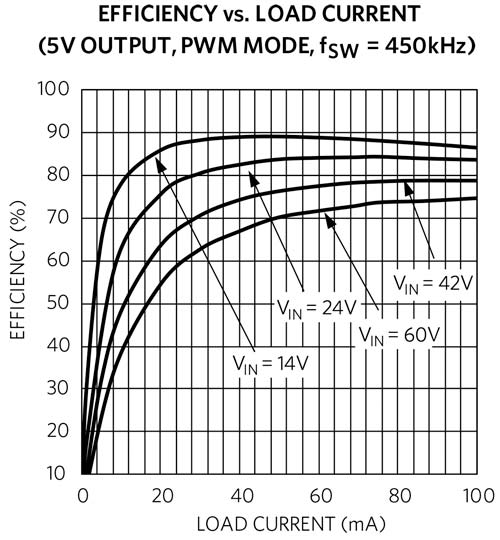

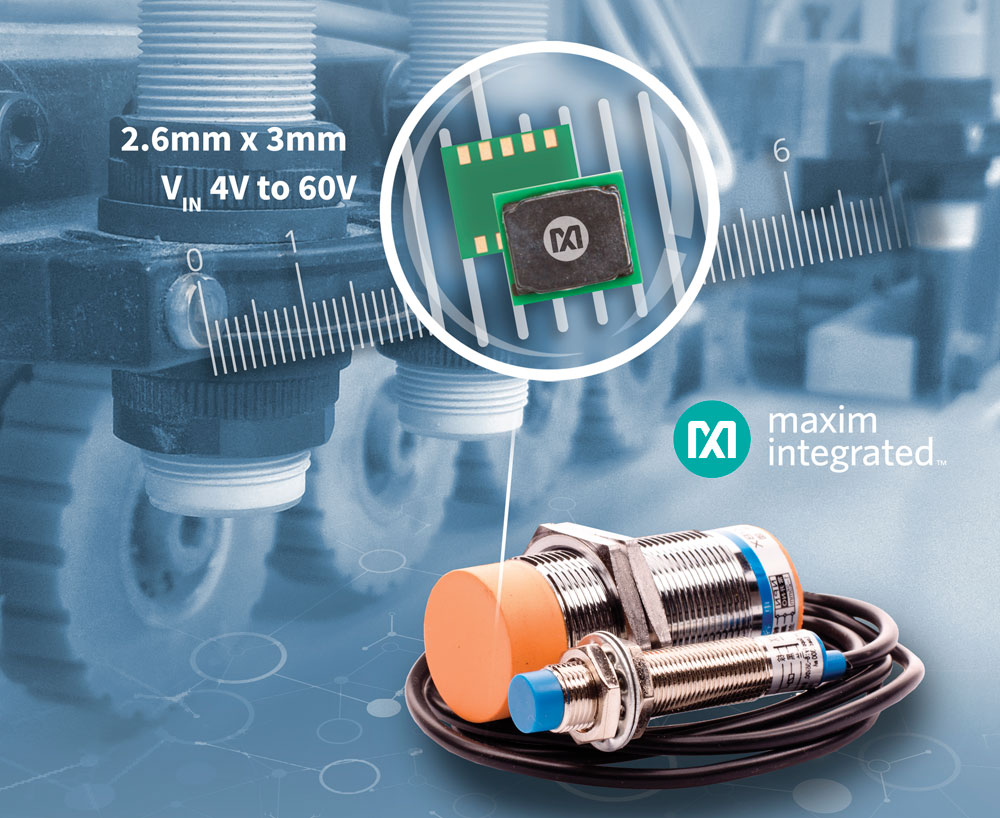

Operating over an input voltage range of 4V to 60V, this micro system-level IC (uSLIC™) provides 100mA of output current with regulated output voltages of 0.9V to 5V. Also, as shown in Figure 5, the efficiency of this regulator is in excess of 80% (at 24V input voltage), while it consumes a total component area of only 14.3mm2. This represents almost a 66% area savings when compared to the previous solution.

Robust Environments

It is also important that power supplies are tolerant to mechanical stresses. This module meets JESD22-B103/B104/ B111 standards for drop, shock, and vibration. Additionally, hiccup overcurrent and overtemperature protection, combined with an operating temperature range of -40°C to +125°C, make this module robust in the harshest industrial, automotive, medical, and military environments. For higher loads (300mA) also operating off input voltages up to 60V, the MAXM15064 Himalaya uSLIC module is available in a 2.6mm × 3mm footprint.

Conclusion

We have discussed the challenges of quickly delivering higher power, more efficiently with minimum heat generation in ever smaller industrial sensors. We saw how a typical LDO solution falls short on efficiency while custom designs using switching regulator ICs can be difficult and time-consuming. We also showed how a power module with a 40V maximum input voltage is not robust enough for the modern industrial environment.

As a solution, we presented two rugged power modules with a 60V input voltage range which can operate in the most demanding industrial environments.

Apart from industrial sensors, they are also suitable for use in motor encoders, HVAC, and building control applications.

About the authors

Michael Jackson has over 20 years’ professional experience as an Analog IC Design Engineer and holds the position of Senior Technical Writer at Maxim Integrated. He has a MSEE from Dublin City University.

John Woodward Graduated from San Jose State University with a Bachelor of Science degree in Electrical Engineering and is an executive business manager at Maxim Integrated.

Glossary

PLC: Programmable Logic Controller. A ruggedized, microprocessor-based system that provides factory or plant automation by monitoring sensors and controlling actuators in real time.

TVS: Transient Voltage Suppressor. Semiconductor device designed to protect a circuit from voltage and current transients. Typically implemented as a large silicon diode operating in avalanche mode to quickly absorb large currents.

LDO: Low-Dropout Linear Regulator. A linear voltage regulator that operates even when the input voltage barely exceeds the desired output voltage.

HVAC: Heating, Ventilation, and Air Conditioning. Industry term for the systems and technology responsible for the heating, ventilation, and air conditioning in buildings. HVAC systems regulate comfort (temperature and humidity), energy efficiency, and air. quality.

Learn more

MAXM17552 4V to 60V, 100mA, Compact Step-Down Power Module (www.maximintegrated.com/en/products/MAXM17552)

MAXM15064 4.5V to 60V, 300mA Compact Step-Down Power Module (www.maximintegrated.com/en/products/MAXM15064)

Visit the Maxim Support Center (https://maximsupport.microsoftcrmportals.com/en-US/support-center)

Find More Design Solutions (www.maximintegrated.com/en/design/technical-documents/design-solutions.html)

Maxim Integrated

www.maximintegrated.com