Navitas Semiconductor (Nasdaq: NVTS), the only pure-play, next-generation power semiconductor company, announces the fifth generation of high-speed GeneSiC silicon carbide (SiC) power diodes for demanding data center, industrial motor-drive, solar and consumer applications.

Navitas Semiconductor (Nasdaq: NVTS), the only pure-play, next-generation power semiconductor company, announces the fifth generation of high-speed GeneSiC silicon carbide (SiC) power diodes for demanding data center, industrial motor-drive, solar and consumer applications.

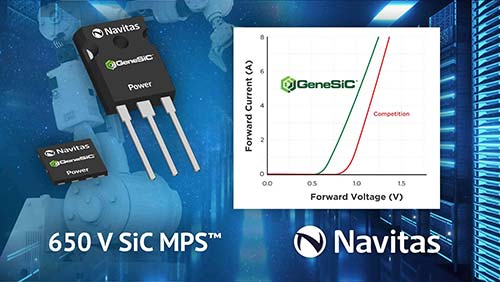

The 650 V-rated Merged-PiN Schottky (MPS™) diodes integrate a unique PiN-Schottky structure, delivering ‘low-built-in voltage-biasing’ (‘low knee’) for the highest efficiency across all load conditions with superior robustness. Applications include PFC in server/telecom power supplies, industrial motor drives, solar inverters, LCD/LED TVs, and lighting.

“We’re delivering reliable, lead-edge performance for in-demand applications like AI and Chat GPT data center power,” noted Dr. Ranbir Singh, Navitas EVP for SiC. “Efficient, cool, dependable operation ensures long lifetimes and brings peace-of-mind to power designers and optimizes their time-to-prototype and time-to-market.”

The novel GeneSiC MPS design combines the best features of both PiN and Schottky diode structures, producing the lowest forward-voltage (VF) drop of only 1.3 V, high surge-current capability (IFSM), and minimized temperature-independent switching losses. Proprietary thin-chip technology further reduces VF and improves thermal dissipation for cooler operation. These GeneSiC diodes are being offered in a low-profile surface mount QFN package for the first time.

To ensure reliable operation in critical applications, the gen-5, 650 V MPS diodes offer best-in-class robustness and ruggedness, with high surge-current and avalanche capability, with 100% avalanche (UIL) production testing.

Ranging from 4 to 24 A capability, in an array of surface-mount (QFN, D2-PAK) and through-hole (TO-220, TO-247) packaging, the GExxMPS06x-series MPS diodes cover applications ranging from 300 to 3,000 W and diverse circuits such as solar panel boost converters, and continuous-current mode power factor correction (PFC) in gaming consoles. With a ‘common-cathode’ configuration, the TO-247-3 package offers great flexibility for high power-density and bill-of-material reduction in interleaved PFC topologies.