Recycling/Glass Industry

Color differentiation of colored glass bottles.

In the glass recycling industry it is necessary to separate the different colored bottles to get a correctly sorted material.

There are different recycling companies on the market and they can be split into two groups: the companies which supply the glass factories and the others which provide the vineyards or the breweries.

The glass factories are only interested in mono-fractions of cullet, whereas the wineries and the breweries are looking for mono-material, nearly 100% sorted and of course, whole bottles. Especially whole bottles can be checked with the color sensor SPECTRO-3-FIO in combination with a through beam optical fiber type D-S-A2.0-2.5-1200-67° and an optical frontend KL-M18-A2.0 at the transmitter side and a KL-M34-A2.0 at the receiver side, respectively.

Wood-Working Industry

Color detection of fluorescent marks on wood plates.

On wooden plates defects will be marked with a fluorescent marker. The fluorescent mark has normally a width of about 15mm and it can happen, that two of this marks lie

20 mm away of each other, but must be detected as two separate marks. Furthermore the fluorescent marks should be detected at a distance of 200 mm to the object and even a mark with a width of 5 mm must be seen.

With the color sensor for fluorescent colors type SPECTRO-3-FIO-UV in connection with an optical fiber type R-S-A3.0-3.0-1200-Y-22°/67°-UV, an optical frontend type KL-M34/62-A3.0 and an external UV lightning source type SPECTRO-3-ELS-UV a proper detection of the fluorescent color marks is possible.

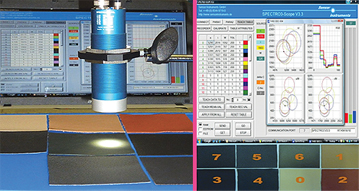

Ceramic-finishing Industry

Detection of fluorescent lines on ceramic tiles.

In the quality inspection of ceramic tiles, one or several fluorescent lines are applied to the tiles, depending on their quality, after manual, visual inspection of the tiles. The task of the luminescence sensor is to detect these individual lines. The number of lines is counted by a PLC and serves as a measure for the quality of the ceramic tiles.

Automobile Industry

Color differentiation of leather and leather imitation (interior equipment).

Leather and leather imitations are used for the interior equipment in the automotive

industry. To avoid any failure during the assembling the color of the respective leather or leather imitation must be controlled.

However, due to the fact, that the color of some different components are very close together, a color gloss control of the components is necessary. Thus, the color gloss sensor SPECTRO-3-50-FCL is used or this task. The sensor is perpendicular directed onto the leather and the leather imitation at a distance of approximately 50 mm.

Edge control of abrasive belts.

The edges of abrasive belts must be grinded to a certain degree. To avoid that the

edges will be grinded insufficient or too much an optical system type SPECTRO-3-FIO-CL in connection with an optical fiber R-S-R2.1-6×1-1200-67° and an optical frontend KL-8 can be used. As shown in the screen shots, the color as well as the contrast of the edge surface is changing dependent of the grinding depth. With the FIRST HIT mode the quality of the edges can be subdivided into maximal 31 different groups.

O’BOYLE SRL

Tel.: +40 (0) 256-201346

office@oboyle.ro

www.oboyle.ro