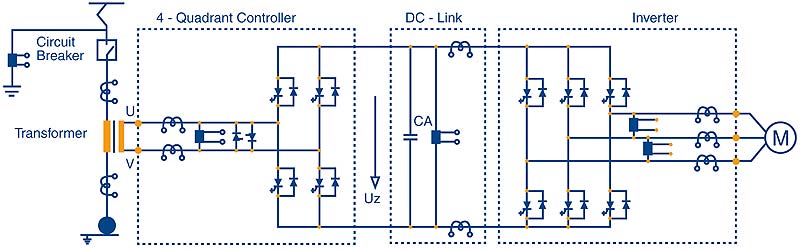

A key element of the propulsion system for low speed urban transportation to high speed intercity trains is the traction converter that transforms the power from the power source, whether a catenary or diesel engine, to drive the electric motors.

The traction converter consists of a rectifier if connected to an AC power source, or a filter in case of a direct connection to a DC grid, as well as an inverter to drive the motor. The DC link is the connection between the rectifier or the DC grid and the inverter. In order to guarantee a sustainable performance, a constant DC link voltage is needed, regardless of the load. To perform the regulation, it is crucial to have a reliable measurement of the voltage level. A key component to perform this task is the voltage transducer.

Trains are required to run in areas with severe environmental conditions, including extremes of temperature, dryness and humidity which means that the traction converters and their components are highly stressed. In addition, the evolution of the technology in power electronics, while bringing significant benefits, also implies that additional constraints are impacting the behaviour of the components.

The main benefit of this evolution for the traction converters stems from the semiconductor industry which, with higher switching frequencies, helps to significantly reduce losses and enables a more compact design. The drawbacks are higher magnetic fields and higher common mode perturbations and voltage transducers are highly impacted by these perturbations.

The old technologies used for these devices are no longer suitable for the new, more demanding, environmental conditions and this is why the new DVM transducer, using the proven patented technology from LEM, is the right solution. It has an extremely high immunity to external magnetic fields and a partial discharge level higher than the maximum DC link voltage. With a compact design, a good accuracy, a very low drift in temperature and the ability to withstand high common mode dv/dt perturbations, the DVM is the perfect choice for DC-link voltage measurement.

LEM new voltage transducer (DVM)

LEM has designed a new range of voltage transducers based on DVL technology (successfully launched in 2012). The result is the DVM series voltage transducers that cover nominal voltage measurements from 600 up to 4200 VRMS (covered with 6 references – Figure 2) and are a way to extend the voltage measurement above 2000 VRMS which is the highest nominal voltage measured with the DVL series. To operate, they only need to be connected to the measuring voltage, without inserting additional resistors on the primary side, and a standard DC power supply range of ±13.5 V to ±26.4 V.

With a primary voltage higher than zero, the transducer consumes a maximum of 30 mA (maximum internal consumption), plus the output current (typically 50mA at nominal value), when set-up with current output.

DVM features a combination of all the advantages of previous LEM products and fulfilment to all new EMC requirements. This product series has been designed according to IRIS and ISO 9001 standards and differentiates from previous generation with the 4 following performances:

• Low consumption of about 30 mA

• Frequency bandwidth 12kHz

• Safety insulation 12 kV

• Very good accuracy in temperature

How does it work?

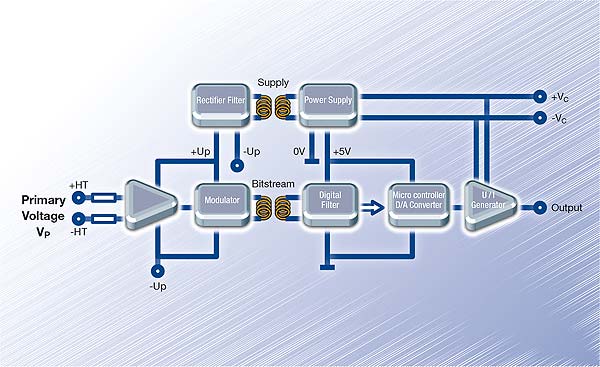

Starting from the left of the diagram in Figure 3 at the primary side, where input voltage might typically be ±4.2 kV, the first stage is a voltage divider that reduces the supply down to a few volts, and is able to withstand high dv/dt while having low thermal drift. Then a sigma delta modulator converts the signal from analogue to digital as a 16-bit output.

This is followed by a digital encoder producing a single serial signal enabling data to be transmitted via one single, isolated channel. Thereafter, an amplifier feeds the signal to the primary side transformer required to provide the desired galvanic isolation.

At the end, the product insulation test voltage is max 12 kV.

The transformer therefore needs to withstand such a high test voltage, while at the same time the lifetime of the insulation can be guaranteed.

This assurance is only possible if a partial discharge of less than 10 Pico coulombs is ensured when a 5 kV voltage is applied between the primary and secondary. The DVM has been specifically designed to achieve that performance.

On the secondary side, the bit-stream is decoded and filtered by a digital filter. Because the primary signal square wave is distorted by the transformer, a Schmitt trigger is used on the secondary side of the transformer to restore it to square wave. This is then fed into a decoder and digital filter; The function of which is to decode the data bit stream into a standard digital value that can be used in digital to analogue converter within the microcontroller. The recovered output signal is completely insulated against the primary (high voltage) and is an exact representation of the primary voltage.

The transducer can be easily adapted for different ranges by modifying the gain programmed by the microcontroller. This does not require changes in the design of the transformer, or in the design of the assembly of the circuit boards in the housing. The microcontroller cancels offsets and adjusts the gain by software and then converts the signal from digital to analogue output. The microcontroller transfers data from the digital filter to a 12-bit D/A converter with a transfer time of around 6 μs. The analogue output voltage is then filtered and converted into a current (±75 mA full scale) using a current generator protected against short-circuits.

The microcontroller also regulates a DC/DC converter that creates internal secondary regulated supply voltages. The DVM user typically supplies ±24V or ±15V DC voltage, while the DC/DC converter allows supply to the sigma delta converter and the digital encoder at primary side with ±5V and ±3.3V. The additional circuitry is shown as a group at the top of the circuit schematic, with the frequency of the DC to DC converter given by the microcontroller.

The last block to the right of the microcontroller is a voltage to current converter for customers who prefer current output, typically 50 mA at nominal voltage, in order to comply with electromagnetic compatibility (EMC) regulations. The lower impedance current output is less prone to interferences from external electromagnetic fields. A voltage output version of 10 V at nominal voltage is also available, as well as a 4 to 20 mA output for unipolar measurements.

Main characteristics

With a typical accuracy of ±0.5% of VPN at ambient temperature, DVM shows a quite low temperature drift resulting in a typical accuracy of only ±1 % of VPN over its operating temperature range from -40°C to 85°C. Initial offset at 25°C is 50µA max with a maximum possible drift of ±100µA (typical) over the operating temperature range. Linearity is only ±0.1%.

The DVM transducer’s typical response time (defined at 90% of VPN) against a voltage step at VPN is of 48µs (Max 60µs). As a result of the fast response time, a large bandwidth has been verified at 12 kHz at -3 dB.

Mechanical and standards

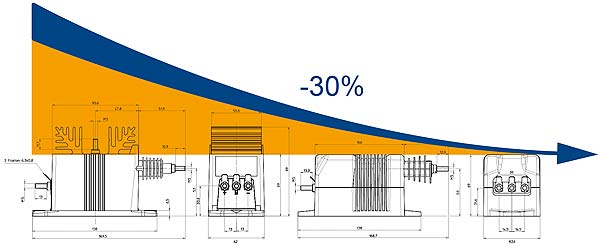

LEM has designed its new products to be compatible and to outperform the previous generations of LEM voltage transducers (LV 100 families). Important features and functions include 100% compatible in terms of functions and performance, and improved levels of accuracy and temperature stability, thus greatly simplifying retrofits.

The DVM series is 100% compatible for the base mounting footprint, but with slight difference in the outline dimensions such as the primary and secondary connection locations. Thanks to a new design, the DVM is smaller in height (30% less) and occupies 25% less overall volume and is 56% lighter! (Figure 4)

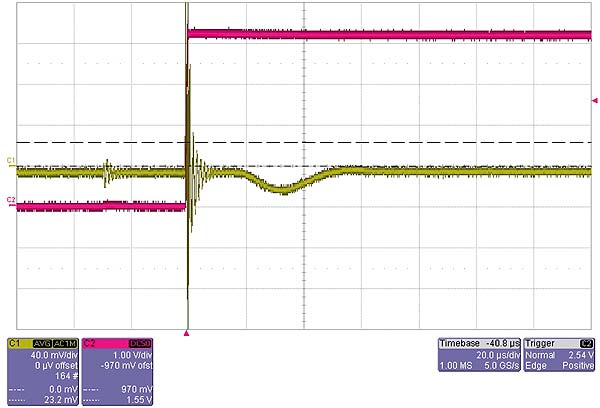

The reduction in size does not compromise the DVM’s high immunity against the external surrounding perturbations or against the high voltage variations, thanks to a highly focused internal electronic design applied on the printed circuit as well as for the mechanic design (Figure 5).

Figure 5: DVM 4000 typical common mode behaviour against dv/dt of 6 kV/us (4200 V applied): Only 0.5% of VPN as error generated with a recovery time of less than 50µs.

The error resulting in common mode condition, with 6 kV/us and 4200 V applied, is limited to 0.5% of VPN with a DVM 4000 and with a short recovery time of less than 50µs, when this can go up to 18% of inaccuracy and 500µs of recovery time with an equivalent LV 100-VOLTAGE in the same conditions of test.

Due to the DVM’s low parasitic capacitance, the effect of dynamic common mode is nearly cancelled out (included in accuracy) (Figure 5), this is an important characteristic as new technologies like IGBT and MOSFETs SIC provide higher dv/dt between primary and secondary. The secondary is generally connected to the ground for safety reasons. The primary is the measurement of differential voltage, but voltage can float. The potential change on the primary can cause a perturbation at the secondary and this cannot be filtered otherwise it would reduce the response time, so the parasitic capacitance between primary and secondary has to be reduced to the lowest possible within the transducer design. The previous generation of voltage transducers LV 100-VOLTAGE models are based on the Hall effect technology in closed loop mode and use a magnetic circuit, making them more sensitive to external magnetic fields where DVM does not use a magnetic circuit.

The DVM allows easy adaptation to input isolator size depending on input voltage, and any kind of connection for the secondary side such as connectors, shielded cables, terminals (threaded studs, M4, M5, inserts, UNC etc.) according to customer specifications.

The DVM models have been designed and tested according to latest recognised worldwide standards for traction and Industry applications. The EN 50155 standard “Electronic Equipment used on Rolling stock” in railway applications is the standard of reference for electrical, environmental and mechanical parameters. It guarantees the overall performances of products in railway environments. For Industry, IEC 61800 for drive applications, IEC 62109 for solar applications, IEC 61010 for safety.

As previously mentioned, special attention has been paid to the mechanical design of the DVM in order to ensure a low level of partial discharges at a high voltage rate. The higher the extinction partial discharges voltage (> 5kV) is, the better it is, as no discharge happens during the normal defined function. The partial discharges level is defined at 10 pC.

As the voltage rises, some partial disruptive discharges start between 2 points, usually at the opposite potentials in any product. Maintaining the discharge levels will reduce the product insulation over the time and then eventually impede the quality of the product until it fails. These discharges happen at a level called the ignition voltage and are defined as disappearing usually when they reach a level of 10 Pico coulombs when decreasing the applied voltage (extinction voltage). Usually the extinction voltage is always lower than the ignition voltage.

To ensure long life products, the goal is of course to have the extinction voltage at a higher level than the normal working voltage rate.

Use of the DVM ensures this, thanks to extinction voltage at 5 kV when the product has been defined to measure nominal voltage from 600 to 4200 VRMS.

Accelerated tests have been performed to estimate failure rate, including temperature cycles as well as complete characterisation of the product according to the standards. Thanks to an innovative design using the insulation transformer linked to digital technology, the DVM models guarantee insulation and partial discharges levels for high voltage applications up to 5kV peak.

Mainly designed for medium and high voltages, DVM transducers are also suitable for any kind of rugged environments, requiring good performance in terms of accuracy, gain, linearity, low initial offset, low thermal drift, etc. Featuring high immunity to external interferences generated by adjacent currents or external perturbations for example and high immunity against high voltage variations, DVM transducers offer excellent reliability.

Author: Michel Ghilardi is a graduate electronic engineer from the University of technology Saint-Etienne in France. He is head of the traction team at LEM R&D having been at LEM since 2001.

LEM | https://www.lem.com