The KVM extender system DP1.2-VisionXG extends computer signals up to 10,000 m via fibre optics and allows users to operate their computers from a distance without latency and jerk-free, as if the computer were still placed directly under the desk

At the SPS IPC Drives exhibition in Nuremberg, Germany, Guntermann und Drunck GmbH will be presenting intelligent KVM solutions for industrial applications from 28–30 November 2017. In applications such as process control rooms or control rooms for monitoring automation processes, both IT and automation have merged more and more over the years. The importance of IT-based structures in the industrial sector is immense and it is therefore impossible to imagine the industry without them. KVM products have been deeply rooted in the industry for decades and enable the spatial separation between computers and operators. This way, computers can be moved into a separate equipment room from where they can be operated from a distance – in real-time, intuitively, latency-free and without judder.

But what are the reasons for removing computers from the production environment or the process control centre? Separating the computer equipment from production or the control centre means improving the working conditions for humans and machines. Rough production conditions such as dust, heat, moisture or electromagnetic fields can affect the devices. Therefore, it is useful to store the computers in a central, air-conditioned and secure server room. There, admins are able to centrally maintain the computers without interfering with the work in production or in the control room.

Industrial automation and intelligent production often require complex computer installations that have to be monitored and operated. With the help of KVM equipment such as KVM matrix switches, it is possible to remove computers from operator stations. The distance to the monitoring centre or to the control room is bridged by modules connected to the central matrix switch. Operators in the control room can thus intuitively monitor the process for several computers simultaneously.

DP1.2-VisionXG – extending computer signals at the highest level

The powerful extender system DP1.2-VisionXG extends computer signals up to 10,000 m – uncompressed and latency-free, thus enabling the transmission of highest video resolutions and best performance for easy and user-friendly operation. The transmission is carried out on fibre optics and therefore provides sufficient bandwidth for high resolutions up to 4K or 8K at a refresh rate of 60 Hz. In addition, fibre optics are insensitive to interference radiation thus making them the ideal fit for the use in industrial applications. Other smaller systems using CAT and fibre optics are also available for industrial applications.

The DP1.2-VisionXG system includes many user-friendly and mission-critical features such as the screen-freeze function, the monitoring function, a redundant power supply, SNMP, and two network ports. The screen-freeze function is a safety feature, which, in case of an issue, “freezes” the image last displayed on the monitor. This state is highlighted by a red semi-transparent frame. Meanwhile, the current time and the downtime of the video signal are displayed.

ControlCenter-Compact optimizes the use of IT equipment in industrial automation

Industrial control rooms and process monitoring are characterized by a distributed and heterogeneous computer landscape. Often, several sources must be monitored at the same time. The use of a KVM matrix, e.g. the ControlCenter-Compact, improves the IT infrastructure and harmonizes spatially distributed installations. KVM matrix systems switch and distribute computer signals and are used whenever several computers have to be operated remotely via different, simultaneous workstations. The matrix switch ControlCenter-Compact is available in six expansion levels providing between 8 and 80 dynamic ports. Special end components make it possible to operate multi-monitor workstations adding to the usability, as control room staff have to monitor several processes and programs running on different computers.

Intuitive operation thanks to CrossDisplay-Switching

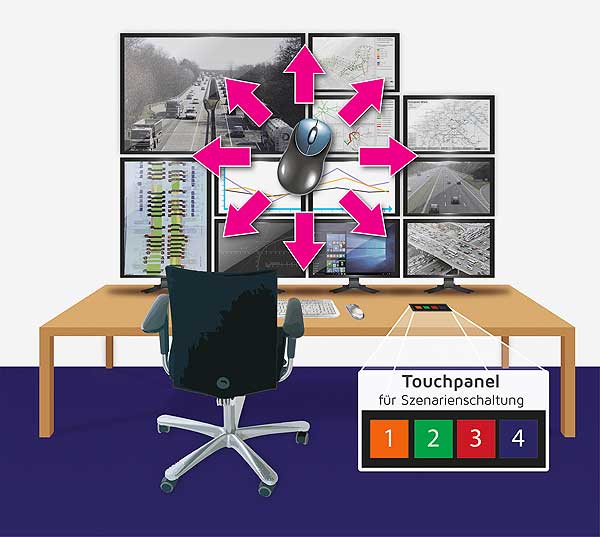

Thanks to its wide range of functions, the ControlCenter-Compact enables simple and intuitive operation to make the work in control rooms as efficient as possible. The integrated CrossDisplay-Switching is extremely useful for multi-monitor workstations. Here, users are able to switch between channels simply by moving the mouse. The mouse acts as if on a “virtual desktop” and can be moved seamlessly across the connected displays. When moving the cursor from the active to an inactive display, the keyboard-mouse focus automatically switches to the connected computer. Thus users work intuitively, do not have to deal with the technology and infrastructure and can concentrate completely on the actual operating processes.

The push-get function, which is available for all digital matrix switches, is also ideal for the cooperation of several operators in industrial control rooms. With this function, users can move the screen contents of a target to (push) – or get it from – the display of another console. This display can be a large screen projection, for example. By using this function, operators can work together on solving issues.

Switching between day and night shifts or generally recurring tasks often also requires the operation and monitoring of different computer constellations. Scenario switching makes it possible to store predefined setups of switching conditions (e.g. day/night scenario). The selected switching status are saved in a script in the matrix system and can be accessed and executed via the OSD of workplaces assigned with the required rights.

G&D have been dedicated to KVM for more than 30 years. Once again this year, the company will be advising interested trade fair visitors at SPS IPC Drives from 28–30 November 2017 in hall 8, booth 228 and helping them find an IT solution tailored to their individual requirements.

Guntermann & Drunck GmbH | www.gdsys.de