Wind energy has become one of the world’s most important renewable energies over the past few decades. Ever rising acceptance and unparalleled technological developments have positioned wind energy as a genuine economic alternative to fossil fuels. Consequently, HARTING will once again be on location at the WindEnergy Hamburg event (September 25-28, 2018), where the technology group will be showcasing its latest products and solutions.

HARTING has continued to develop the lightweight Han-Eco® B plastic connector (left). In addition to its insensitivity to external environmental influences, the Han-Eco® B allows rear mounting of the contact inserts in the mounting housing, which can save considerable costs in the manufacturing process. This year, the focus will be on the new fiber optic rotary transmitter (right) with bidirectional data transmission.

Increasing digitisation, in combination with ever larger turbines, is confronting the wind power industry with steadily increasing data volumes. Consequently, the trouble-free and fast transmission of this data is absolutely essential for many wind farm operators. In order to meet this trend, this year HARTING is focusing on the new fibre optic rotary transmitter with bidirectional data transmission. The transmitter meets the requirements for even faster exchange of large data packets between the nacelle and the rotating hub. The wear-free and maintenance-free system offers end-to-end optical fibre-optic networking of the entire system – from the tower base over the nacelle to the hub.

At WindEnergy Hamburg, HARTING will present rectangular current sensors for mounting on busbars (left), as well as the Han® ES Press with jumpers on the insulating body. The Han® ES Press gives customers the opportunity to quickly perform tool-free wiring or make changes in the field.

To support this system, HARTING developed the MICA® (Modular Industry Computing Architecture). MICA makes it possible to store, evaluate and process data directly in the application environment and can be configured with individual hardware, freely available software and suitable interfaces – in a manner that entirely meets customers’ individual requirements.

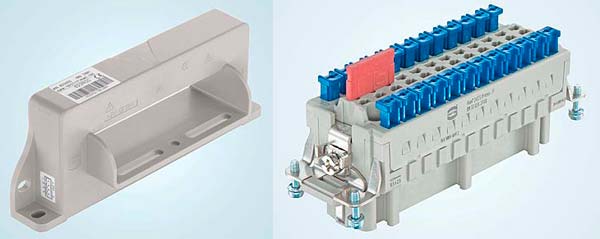

In addition, HARTING will showcase its product innovations in its broad portfolio of connectors with high-performance plastic and corrosion-resistant aluminium housings. These include innovations within the Han-Eco® series. Introducing the new Han-Eco® B, HARTING has developed a plastic connector that is fully compatible with the industry standard Han® B while at the same time combines all the advantages of a plastic connector. In addition to being impervious to external environmental influences, the

Han-Eco® B allows rear mounting of the contact inserts in the bulkhead mounted housing, which can save considerable costs in the manufacturing process. The Han-Eco® Snap rounds out this continuous expansion of the portfolio. The Snap was designed for indoor applications and, with its separately detachable upper housing part, not only facilitates installation, but also enables potential measurement in an installed state. In addition to all standard inserts, the Han-Eco® series can also use modules in conjunction with the articulated frame from the Han-Modular® range. The Han® ES Press gives customers the opportunity to quickly perform tool-free wiring or make changes in the field.

In addition, at WindEnergy Hamburg HARTING will be presenting the overvoltage module that can be integrated into the connector. Thanks to this connector, an applied overvoltage potential can be safely dissipated within the connector even before entering the switch cabinet. The new HARTING LED light features as another highlight at the show. The optimised design delivers 35 percent better light output. This leads to a cost reduction in the overall solution for tower equipment, since fewer total lamps are required in the system. Further innovations at the trade show include various current sensors. For example, HARTING is now featuring rectangular current sensors in its portfolio. The sensors are suitable for optimum installation on busbars and can measure currents up to 5,500A.

“HARTING has been involved in wind energy for over 35 years. Given our experience, we can offer our customers cost-optimised and tailor-made solutions,” as Christian Bohne, Industry Segment Manager Wind Energy at the Technology Group, states.

HARTING Technology | www.HARTING.com