Due to the high demand for medical technology, LASER COMPONENTS Detector Group has switched its production of IR detectors to multi-shift operation. The components manufactured in Arizona are important key elements in the examination of the CO2 level in breath gas analysis. Due to the current situation, production capacities in the medical technology sector must be increased significantly to provide urgently needed equipment.

Due to the high demand for medical technology, LASER COMPONENTS Detector Group has switched its production of IR detectors to multi-shift operation. The components manufactured in Arizona are important key elements in the examination of the CO2 level in breath gas analysis. Due to the current situation, production capacities in the medical technology sector must be increased significantly to provide urgently needed equipment.

In spectroscopic breath gas analysis, PbSe detectors can quickly detect the smallest fluctuations in CO2 concentration even without additional cooling. They can therefore be integrated into medical devices in a space-saving manner. In ventilators, the carbon dioxide content of exhaled air is measured to check whether the patient has absorbed the oxygen provided.

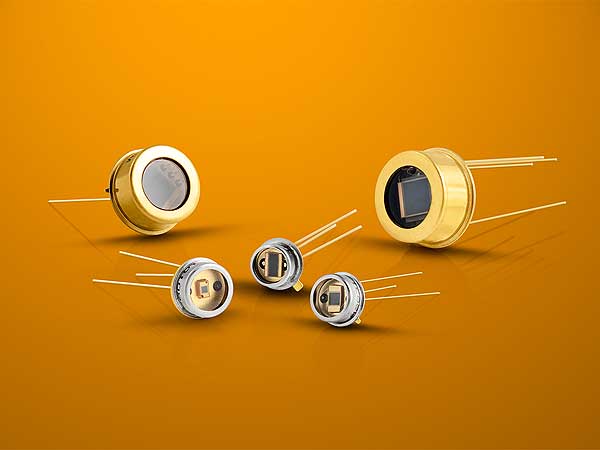

LASER COMPONENTS Detector Group’s portfolio includes all common IR technologies. The production facility in the U.S. state of Arizona primarily manufactures (x-)InGaAs-PIN photodiodes, pyroelectric DLaTGS and LiTaO3 detectors, and PbS and PbSe detectors. With many years of experience and employees who are known in the industry as proven experts, LASER COMPONENTS Detector Group has established itself as the global market leader for PbSe technology. In the E.U., LASER COMPONENTS is leading the campaign to extend RoHS exemptions to continue use of this technology in such important industries as medical technology.

LASER COMPONENTS’ IR detectors are supplied to well-known medical technology manufacturers. Coordination with these customers currently determines the international day-to-day business in order to ensure rapid delivery of critical components.