As of January 2010, smart electricity meters are compulsory for all new installations. Utility companies must also offer such meters to their existing customers. Smart meters can perform significantly more functions than the conventional

Ferraris meters: They measure current and voltage, store the data, display and transmit these and communicate with other devices. Component manufacturers have responded to this and are offering components that meet these requirements.

by Ralf Hickl, Microcontroller Support Rutronik Elektronische Bauelemente

Front end: Sensors and signal processing

In order to measure electric energy electronically, the signals for current and voltage are received, are converted from analogue to digital, are multiplied and integrated. Shunt resistors, current transformers (transmitters that are virtually short-circuited on the secondary side) and Rogowski coils are suitable sensors for measuring the current. Unlike the measurement using shunt resistors, the two inductive transducers offer the advantage of galvanic isolation.

However, this only has an effect if both the power supply unit and the mains voltage measurement are also equipped with a galvanic isolation, which is associated with significant additional costs.

Because of their high resolution, analogue-digital converters of the delta/sigma type are used – either already in the front end or in the microcontroller.

The MCP3901 from Microchip is composed of two independent delta / sigma AD converters with internal reference voltage source and upstream programmable gain amplifiers (PGAs).

A microcontroller can read the conversion results via a SPI interface. The serial interface allows for easy galvanic isolation via optocouplers. Shunts and voltage dividers are used for measuring the mains current and the voltage. Depending on the required resolution, sampling rates of up to 64KSPS can thus be achieved. Several MCP3901 are necessary for multi-phase energy meters.

Microchip complements developments using the MCP3901 with an application note (AN 994, IEC meter design) and an evaluation board.

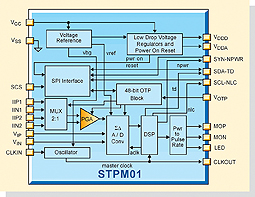

The STPM01 from STMicroelectronics, which has successfully been used on the market for several years, is especially suited for single-phase energy meters. In the STPM01 as well, two independent delta/sigma converters digitise the increased current and voltage input signals. Current transformers, shunts and Rogowski coils can be used as current sensors. Alternatively, the currents can be measured in the forward and return conductors, while any fault currents are reported as tampering attempt. A reference voltage has also been integrated.

A digital signal processor on the chip calculates the energy and the effective values. In single operation, the STPM01 controls a stepper motor for a roller counter. In combination with a microcontroller, the determined values are read via a SPI interface. STMicroelectronics offer several evaluation boards for developments using the STPM01, which differ only by the type of current measurement.

The two new ICs STPMS1 and STPMC1 from STMicroelectronics allow for the construction of a flexible, multi-phase energy measurement device. The front end, which is called the STPMS1 or also smart sensor IC, is a two-channel analogue digital converter working according to the sigma/delta principle with a resolution of 16 bits. Up to five of these smart sensor ICs are connected to the data processing IC, the STPMC1, via synchronous serial interfaces. Each STPMS1 digitises the current and voltage of one phase R, S, T or N. Shunts, current transformers and Rogowski coils can be used for measuring the current. The fifth input of the STPMC1 has been provided for the signal from a Hall sensor. Using internal DSP functions, the STPMC1 calculates the values for voltage, current and energy. For this purpose, the STPMC1 can be adjusted and calibrated via an internal OTP memory. As it is equipped with a SPI interface and a stepper motor output, the data-processing IC supports operation both with and without microcontroller. Evaluation boards are currently being developed.

The microcontroller

The selection of the microcontroller depends on the complexity of the front end and the communication interfaces. Basically, low-power microcontrollers with integrated drivers for liquid crystal displays are suitable. A meter that uses the MCP3901 from Microchip requires a relatively high processing power as – unlike the building blocks from STMicroelectronics – it does not have a built-in DSP unit and consequently, the values for current, voltage and energy from the converted signals still need to be calculated. It is recommended to use a digital signal controller from Microchip’s dsPIC family or directly a PIC32.

In a solution using STPMxx, the microcontroller must merely display the data already determined in the front end and must operate the interfaces to the outside. A low-cost 8-bit microcontroller is sufficient for this purpose, for example a derivative of the new STM8L series with integrated LCD driver. Where demands on the processing power and the interfaces are higher, a STM32 offers good value for money. Very long data preservation and protection against tampering are ensured by a mask programmed microcontroller.

Unfortunately, the number of manufacturers offering these is decreasing, EPSON being one of them.

In addition to processing and displaying, however, other essential functions are required, for example an energy buffer or the recovery of meter readings in non-volatile memories in order to bridge network interruptions. In addition, the memory should provide protection against unauthorised reprogramming and tampering. Long data preservation in the program memory would be another desirable feature, as house and apartment owners are used to meters with a long life. Furthermore, an integrated calendar with clock and a buffer for logged readings should be provided.

The measures for the detection and reporting of tampering attempts and energy consumption at the electric meter box are summarised as anti-tampering measures. In the front end, this is done by fault current measurements. The total of the phase currents and the current passing through the neutral conductor must be zero. Any deviations that exceed a certain threshold are detected and will lead to a response. Any isolation faults can also be detected. For safety reasons, the load should be separated automatically from the mains in this case. Conventional energy meters do not offer this load separation function, whereas it will certainly increasingly be used in power filling stations for electric cars. In addition, there are no limits to the ingenuity of the device manufacturers:

Tampering attempts could also be detected by housing contacts or the measurement of incident light into the case, a change in the mounting position or the acceleration.

No standard yet in communication technologies

At present, it is still unclear which technology will prevail as the standard used for smart meter communication. Rutronik is favouring an Internet connection to the utility company and a power line communication between the meter and the switch of the consuming appliances. The line-bound method offers the advantage that it uses the existing infrastructure and that therefore no additional costs for cabling are incurred. In addition, the communication also works through walls. In view of the fact that the infrastructure in every building looks different, however, there may be situations where sufficient reliability cannot be ensured. In these cases, wireless connections would represent a useful alternative.

The modem ST7540 from STMicroelectronics needs a host CPU with that it communicates via a SPI interface. It uses frequency shift keying with adjustable carrier frequencies in the CENELEC A or B band as modulation method on the network side. The baud rates can be programmed and go up to 4800Bd Development tools are available also for the ST7540, which consist of a transceiver evaluation board with the ST7540 and a power line transceiver communication and control board, which is based on the ST7 microcontroller family from STM. Using a PC GUI, developers can configure the ST7540 and send and receive simple messages.

Components and know-how

For broadband distributors like Rutronik, the new meters are particularly interesting: Almost the whole range of electronic components is installed in these so that the benefits of a broad and deep product portfolio are particularly evident. Since different solutions are available from several providers for each task, the components can be adapted to specific requirements and can also be optimally coordinated with each other. In this regard, Rutronik does in no way put quantity before quality: all providers are selected according to strict quality criteria. The distributor places particular attention to its function as a manufacturer-independent and therefore objective consultant. Field application engineers and product managers support and advice the customers and also assist them during the design-in. Expert support is essential especially in a market like this where no standards have yet been established.

www.rutronik.com