The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, is releasing THERM-A-FORM™ CIP 60, a high-performance cure-in-place material and thermal gap filler that offers excellent 6.0 W/m-K thermal conductivity. This innovative product not only provides an attractive alternative to hard-curing dispensable materials in electronics cooling applications, but also offers an improvement over standard application methods associated with thermal gap filler pads.

The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, is releasing THERM-A-FORM™ CIP 60, a high-performance cure-in-place material and thermal gap filler that offers excellent 6.0 W/m-K thermal conductivity. This innovative product not only provides an attractive alternative to hard-curing dispensable materials in electronics cooling applications, but also offers an improvement over standard application methods associated with thermal gap filler pads.

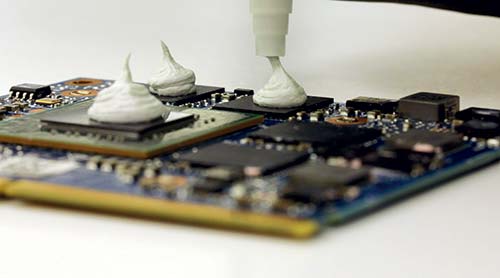

As a two-component dispensable material, THERM-A-FORM CIP 60 has an exceptional flow rate and is dispensable in high volumes. With a 1:1 mix ratio, the material offers easy dispensing through a static mixing tip using either manual or automated equipment. THERM-A-FORM CIP 60, which also has vibration damping characteristics to meet the demands of challenging operating conditions, requires no pre-mixing or weighing of components.

The product is particularly suitable as a thermal fill material in applications that need heat transfer in challenging or irregular geometries, such as cooling multi-height components on a printed circuit board (PCB) without excessive force. Design engineers can thus avoid the expense of a moulded sheet.

The product is particularly suitable as a thermal fill material in applications that need heat transfer in challenging or irregular geometries, such as cooling multi-height components on a printed circuit board (PCB) without excessive force. Design engineers can thus avoid the expense of a moulded sheet.

THERM-A-FORM CIP 60 resists sag when curing, a process that takes 60 minutes at 110°C or 24 hours at 25°C. At full cure, the product has a Shore hardness of 50 (according to ASTM 2240 test method) and can operate in temperatures from -50°C to +200°C.

Offering a blend of high thermal conductivity, flexibility and ease-of-use, applications for this RoHS-compliant product include: automotive e-mobility systems such as converters and inverters; automotive infotainment systems like panel displays, HUD (head-up display) units and audio equipment; automotive ADAS (advanced driver assistance systems) encompassing DCU (domain control units), camera systems and radar/lidar systems; and consumer and enterprise SSDs (solid-state drives).

The formulation of THERM-A-FORM CIP 60 brings advantages to modern high-performance, high-reliability electronics with properties that include: 125 kVac/mm dielectric strength (ASTM D149 test method); 1013 Ωcm volume resistivity (ASTM D257); 69.3 dielectric constant at 1,000 KHz (ASTM D150); and 0.006 dissipation factor at 1,000 kHz (CHO-TM-TP13).

THERM-A-FORM CIP is available in ready-to-use, dual-component cartridge systems (50, 200 and 400cc) that eliminate the need for weighing, mixing and degassing.

Learn more about THERM-A-FORM CIP 60 here.