You have to be able to count on your systems 100%!

Under no circumstances is a connector allowed to be responsible for a system’s malfunction. And this is why you should make no compromises here when it comes to the functionality, quality and contact stability.

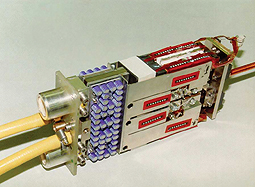

Various contact technologies are available on the market, such as hyperbolic, lamella, coil spring, etc. All of these systems can transfer current and voltage, but the spring wire contact technology from ODU, offers the greatest contact stability. A multitude of individually cushioning contact springs ensure constant power transmission, even under difficult conditions such as vibrations. Even at a contact diameter of 0.76mm, 16 individual contact springs are built in, meaning 16 contact points for the power transmission.

The most important data at a glance

• Proven technology, with more than 60 years of experience;

• Far more than 100,000 mating cycles, long product service life;

• High current-carrying capacity up to 2,000 A;

• Lowest contact resistances;

• Large number of independently cushioning contact springs, e.g., 40 pieces with Ø 5;

• Low insertion and withdrawal forces;

• Extremely certain contacting;

• Constant power transmission, even under difficult conditions; such as vibrations or temperature fluctuations;

• Simple fabrication– screw or crimp connection;

• Both round and flat versions are available as “single contacts”.

Field of application:

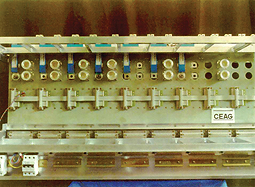

Power supply for Insertion systems

Power supply for processors

ODU Springtac contact 1500 A for power supply

Contact stability is important no matter what the branch, and so ODU’s springwire contacts are used in all markets of the future, such as medical technology, renewable energies, industrial electronics, automation, etc.

Contact:

Eng. Alina Cibu

E-mail: alina.cibu@odu-rom.ro

www.odu-rom.ro

ODU ROM Manufacturing – Sibiu, Romania

Tel: 0748144488; Fax: 0269 221006

For general information visit: www.odu.de