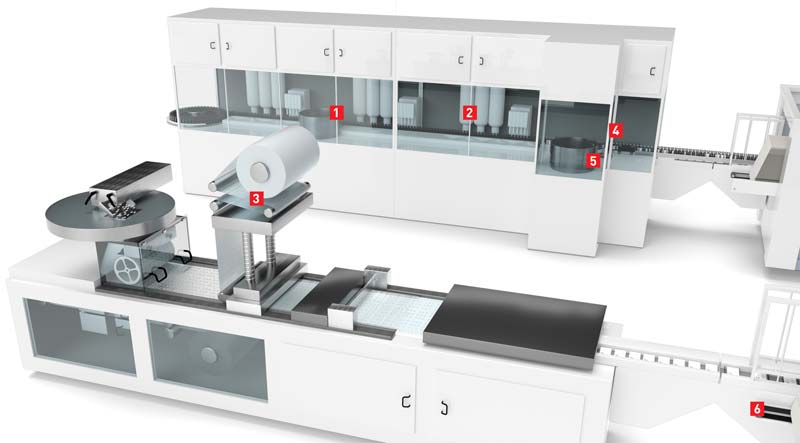

The packaging process mainly involves tablets being packed in blisters and various liquids being filled into small glass and plastic bottles. Owing to the strict hygiene standards, stainless steel is often the only material allowed for the components used.

The packaging process mainly involves tablets being packed in blisters and various liquids being filled into small glass and plastic bottles. Owing to the strict hygiene standards, stainless steel is often the only material allowed for the components used.

Maximum safety requirements apply during the production and packaging of pharmaceutical products.

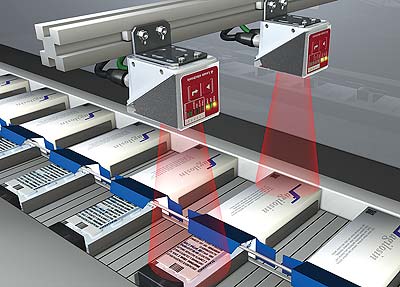

To protect against falsification, code readers must guarantee 100% decoding. The DCR 200i bar code scanner reads all codes and ensures the traceability of the production and packaging process for all products. With its hygienic stainless-steel housing, it is ideally suited to the demands of the pharmaceutical industry.

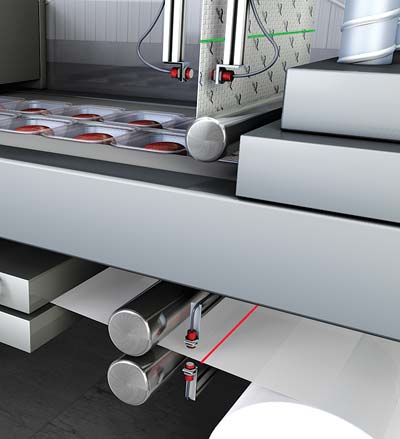

The hygiene design stainless steel sensors of the 53 series use laser technology to reliably and quickly detect even minute vials. Many challenges involving the detection of self-adhesive labels in the labelling station can also be mastered: For example, the GSU 14D forked sensor can reliably detect virtually invisible clear-on-clear labels.

In quality control, the LRT 8 luminescence sensor also reliably checks the presence of attached paper labels.