Quality is one thing, because no one wants to be accused of not being a quality product. “Thus, even in the marketing of metals extracted from primary raw materials, buzzwords such as “solder of primary smelting” and the like persist. Due to the inflationary use of the quality term “primary smelting”, however, the standards slip and it is suggested to the market that only solders from this primary smelting are of high quality. This is not the case, this claim is false. This is why we have launched the GreenTin+ on the market,” says Tobias Patzig, authorised signatory of Feinhütte Halsbrücke GmbH. Reason enough to fight the persistent myths and half-truths. It must be emphasised that the material origin of metals does not necessarily say anything about the purity or quality of the material. Unlike raw materials such as paper or plastic, for example, metals can be recycled as often as desired without any loss of quality or, as in the case of GreenTin+ from Feinhütte Halsbrücke GmbH, even upcycled. With a purity level of 99.99 %, the tin GreenTin+ obtained from recycling processes clearly surpasses the quality of imported tin from primary raw materials.

Quality is one thing, because no one wants to be accused of not being a quality product. “Thus, even in the marketing of metals extracted from primary raw materials, buzzwords such as “solder of primary smelting” and the like persist. Due to the inflationary use of the quality term “primary smelting”, however, the standards slip and it is suggested to the market that only solders from this primary smelting are of high quality. This is not the case, this claim is false. This is why we have launched the GreenTin+ on the market,” says Tobias Patzig, authorised signatory of Feinhütte Halsbrücke GmbH. Reason enough to fight the persistent myths and half-truths. It must be emphasised that the material origin of metals does not necessarily say anything about the purity or quality of the material. Unlike raw materials such as paper or plastic, for example, metals can be recycled as often as desired without any loss of quality or, as in the case of GreenTin+ from Feinhütte Halsbrücke GmbH, even upcycled. With a purity level of 99.99 %, the tin GreenTin+ obtained from recycling processes clearly surpasses the quality of imported tin from primary raw materials.

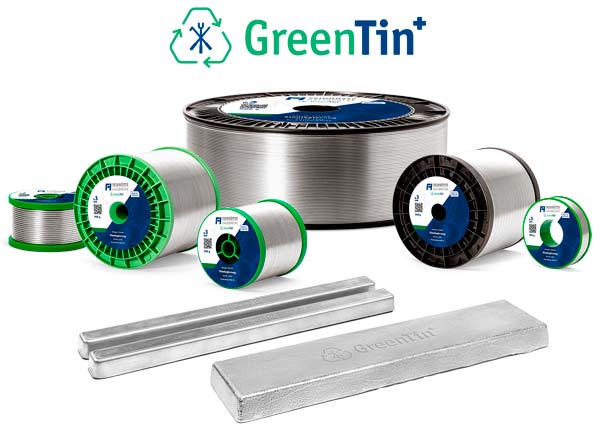

The quality of the metals offered in the form of wire, ingots, bars, bulk material or similar is determined by the know-how and efficiency of the manufacturing process. Furthermore, in the recycling process of old solders and secondary materials such as dross, ashes, runners, sludges, chips or solder pastes, the underlying effort and the quality of the work steps have a positive effect on the material quality. The origin or geographical provenance of the materials, on the other hand, are not decisive, which is why recycled metals also offer the advantage of independence from international supply chains.

Extensive processes

Furthermore, there is no “primary smelting” in the true sense of the word for either primary or secondary raw materials. Rather, both smelted ore concentrates (primary) and process residues (secondary) must undergo a refining process in order to be able to remove by-elements such as copper, iron, antimony, arsenic, lead, indium and bismuth. At the same time, the processes underlying the recycled metals have a significantly better balance in terms of avoiding air and water pollution and water consumption in direct comparison to the primary materials. “Recycling processes are also convincing with more efficient energy requirements and lower CO2 emissions at the same time,” Patzig discusses. However, it is not only the general negative burdens in the entire ecosystem that can be significantly reduced with recycling processes. “With the use of secondary materials, further mining of basic raw materials can be avoided, which is questionable for both ecological and humanitarian reasons,” Patzig continues.

Furthermore, there is no “primary smelting” in the true sense of the word for either primary or secondary raw materials. Rather, both smelted ore concentrates (primary) and process residues (secondary) must undergo a refining process in order to be able to remove by-elements such as copper, iron, antimony, arsenic, lead, indium and bismuth. At the same time, the processes underlying the recycled metals have a significantly better balance in terms of avoiding air and water pollution and water consumption in direct comparison to the primary materials. “Recycling processes are also convincing with more efficient energy requirements and lower CO2 emissions at the same time,” Patzig discusses. However, it is not only the general negative burdens in the entire ecosystem that can be significantly reduced with recycling processes. “With the use of secondary materials, further mining of basic raw materials can be avoided, which is questionable for both ecological and humanitarian reasons,” Patzig continues.

Quality determining specifications

Ultimately, the quality is determined by the specification of the metal or alloy and the metallurgical process techniques used. Accordingly, recycled material can also be used to produce extremely high-quality end products, for example in electronics manufacturing for power electronics. Nevertheless, there have been repeated attempts to discredit recycled material, especially in the electronics industry. “The reservations cited in this context can be confidently dismissed as myths, fables and ignorance. Or as a pure marketing campaign. In any case, they are unfounded,” says Patzig.

The formats obtained from recycled metals with sound expertise, modern pyro- and hydrometallurgical plants and with optimised production processes are in no way inferior to the quality of primary raw materials. Quite the opposite, as can be impressively demonstrated with GreenTin+. “Secondary materials are excellently suited for the production of high-performance solders,” emphasises Patzig.

Ultimately, environmentally friendly mining of ores and the best possible valorisation of products and product residues are required if the globally increasing demand for raw materials is to be sustainably secured in the future.

Feinhütte Halsbrücke will present the GreenTin+ and other material innovations at the joint stand of Emil Otto, Feinhütte Halsbrücke and Eutect at productronica 2021, Hall A4, Stand 315.