The product group includes the pastes Alusol-SN and -SN-X. Both pastes must be stirred well before use. The paste is applied with a brush or similar accessory then. In the case of overlapping workpieces, the overlaps should also be slightly coated with the paste. The application condition is achieved by heating in the oven or by hot air, flame, or piston to min. 250 °C. Due to the excellent activity of the contained flux, the Alusol solder paste spreads very well on the surfaces of the workpieces and penetrates perfectly into soldering gaps and cavities.

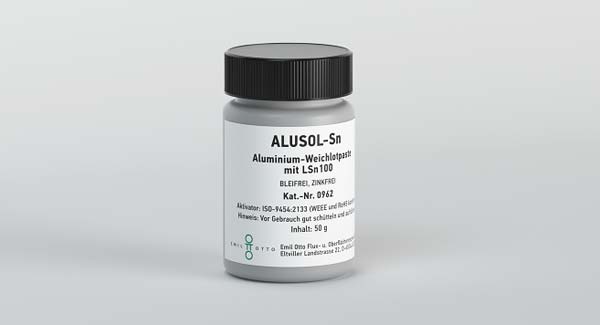

After the soldering process, the easily water-soluble flux residues can be removed. This is done by immersing the still warm workpiece in cold or lukewarm water. The different thermal expansion coefficients of the materials and flux residues cause them to separate from the metallic workpiece. Both pastes are offered in a 50 g brush bottle or a 300 g bottle. “With our special solder, it should be emphasised that all further handling, such as complex soldering with solder wires or similar, is no longer necessary. This makes the soldering of workpieces made of aluminium much easier,” explains Markus Geßner, Marketing and Sales Manager at Emil Otto GmbH.

Deeplinks:

https://xn--khler-weichlten-bandverzinnung-48c4p.de/produkt/alusol-sn/?lang=en

https://xn--khler-weichlten-bandverzinnung-48c4p.de/produkt/alusol-sn-x/?lang=en

EMIL OTTO Flux- u. Oberflächentechnik GmbH