The average age of the population is increasing – and with it the requirement for medical care and monitoring. The number of medical practitioners, on the other hand, has remained relatively constant. The Federal Employment Office has already reported on a lack of doctors in many European countries. One challenge we are facing is increasing the efficiency of medical care without jeopardising quality and safety. Mobile systems can make a significant contribution in this regard.

By Bernd Hantsche, Product Area Manager Wireless Competence Center, Rutronik Elektronische Bauelemente GmbH and Tobias Mühlhäuser, Product Area Manager Wireless Competence Center, Rutronik Elektronische Bauelemente GmbH

The use of sensitive data, processes, substances and devices in medicine often determines life or death. Protection against misuse and incorrect use and the monitoring of important data therefore plays a crucial role in diverse circumstances. In addition, remote monitoring of people at risk considerably reduces expenditure, making the work of doctors and nursing staff more efficient while at the same time improving the quality of life for many patients. RFID technology offers safe and cost-efficient solutions in this regard.

Depending on the measurement system and the area of application, medical devices have different power supplies. Accordingly, they have to use their energy capacity economically, which is also true for the wireless interface. In a passive wireless transmission that does not actively send data the energy efficiency of the transponder in practice corresponds to the theoretical optimum value. Here, the microcontroller is connected via I²C interface to the M24LR64, for example, a new dual EEPROM interface from ST Microelectronics. The second interface of the 64kbit memory chip is a 13.56MHz RFID antenna connection that works according to ISO15693. The 64 memory blocks with 1 kilo bit each can independently be protected by password against RFID write access or even RFID read access. The microcontroller writes the measured data into the EEPROM from where it can be retrieved from externally by an RFID reader, if necessary. The doctor can define some memory blocks with control parameters for the measuring system via RFID, for example with new waiting periods between the measurement cycles. Since the data transmission only requires the energy of the external reader, for example an RFID capable PDA, the application on the patient can be completely without current. No active sending takes place so that no energy is required on the side of the measuring system.

Mobile basic stations combine data collector and gateway

Monitoring the health of a patient often requires several devices, like for instance ECG and blood sugar measuring devices, body fat scale and special blood, urine and sweat analysis units. A chest strap, scale and blood sugar measuring device send readings via a local wireless network, such as Bluetooth, ANT or 6loWPAN, to a data collecting instrument at the home of the patient. Up to now, such stations have been connected to the health service points via telephone line. However, the trend goes away from physical cable connections to cellular and thus more flexible wireless technologies. This has various reasons: Firstly, the monthly operating costs for GPRS are now less than ISDN. Secondly, thanks to a storage battery buffer, such devices allow for mobile use, for example during the patient’s business or leisure travels.

This increases the quality of life of the patient while ensuring uninterrupted health monitoring. The medical service computer analyses the data. If measured values or a combination of these exceed defined limit values, depending on the urgency, the computer sends an email or SMS containing the relevant information to the attending doctor. The latter can thus respond in the appropriate manner within minimum time. Especially in such storage battery operated measuring devices, current consumption and the mechanical dimensions are increasingly important. At present, the Telit GE865 optimally fulfils both requirements: Measuring only 22 × 22mm in BGA design, it requires minimum space on a PCB and, thanks to the latest single chip GPRS architecture in the form of an Infineon X-Gold, has the lowest current consumption in the area of wireless modules.

Similar systems can also be used for sending the measured values of a sensor in a prosthesis or an implant to the database of the doctor. All that is required for this is a semi-passive RFID system combined with a GPRS gateway. During the process, the sensor values are stored in the RFID chip, read out if necessary, and sent directly to the doctor via mobile communication. The ISO15693 compatible RFID transponder chip from ZMDI, for example, has an interface for external sensors. It has an 8kbit EEPROM for storing the sensor data. As RFID reader with GSM gateway, the iDTRONIC offers a wide portfolio of RFID readers that can optimally be combined with GSM modules, for example those from Telit.

Wireless identification of doctors and patients

In old-age homes or convalescent centres, several patients often share the same devices and user identification is therefore required. Several methods are available for this purpose: Manual identification may result in many errors, for example due to incorrect entry. Biometric processes are very costly and require significant computing power. The electronic ID card with RFID, which the patient carries as wristband or key ring with integrated transponder chip, for example, is reliable, low-cost and, thanks to modular readers, can very easily be implemented in existing applications. This type of identification via the integrated unique ID makes manipulation impossible. Furthermore, additional memory space can be used for parameters that the patient also carries with him/her, such as information on his/her illnesses or the required medication. Any person assisting the patient can quickly and conveniently check before giving the patient food or medication whether this is tolerated by the patient; studying the patient folder is not required.

Identification of the staff also plays an important role in the medical sector – after all, it must be ensured that only authorised persons have access to highly dangerous substances or vital equipment. In this case, it is possible to store, in addition to the User ID, data such as permitted access areas and times on the chip.

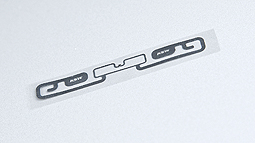

Not only people, but also accessories can be identified or marked in this way. It is therefore possible, for instance, to implement inlays, e.g. from KSW Microtec, directly in the accessories for bone processing devices. The reader in the device itself identifies the accessories and authorises the corresponding operating functions. Errors due to the connection of incorrect accessories or due to incorrect handling can almost be excluded. The RFID technology also offers efficient control options for accessories that may only be used once. For example, a reader in a tattoo gun can identify an attached needle module, possibly detect that it has already been used and disallow its re-use.

Safe protection for sensitive substances

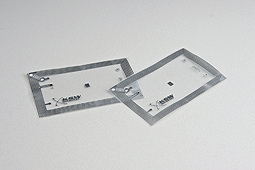

Many products used in the medical environment are extremely sensitive to temperature, for example stored blood, organs, or certain medication. With RFID technology, temperatures can conveniently be monitored. KSW Microtec have developed the VarioSens® especially for this application. The tag in ISO card format includes a transponder chip, an antenna, a temperature sensor, and a battery. Here as well, we speak of a semi-passive RFID system since the battery supplies only the temperature sensor and is not required for the data transfer. The time interval required for storing the temperature values can freely be set between two seconds and nine hours.

Another major safety risk in the area of medication are imitation products: Not only do they cause financial losses for the manufacturer, what is more serious is that they might be harmful to a patient’s health. An electronic certificate of authenticity for medication packaging is to provide protection against product piracy. The use of RFID ensures continuous control of the medication from the manufacturer to the patient. For example, the RFID Tamper Proof from the Schreiner Group, a self-adhesive RFID label, can be stuck on the medication packaging.

When an attempt is made to remove the label from the original product, it self-destructs. Combined with the unique ID of the transponder chip, the product is identified in an unequivocal and tamperproof manner.

System concepts instead of component fixation

Irrespective of the area of use, the requirements for the solutions are mostly the same: It should be possible to use the devices without any intervention by the patient, the battery lifetime should reach a therapy period, i.e. at least six months, and storage battery-operated devices should work for a week without the need to connect

them to the power supply. In addition, companies increasingly request a modern unit design that distinguishes them from the competition. As a result, the electronics should be designed as small as possible and must function with only little current consumption. The devices do not require controlling as they can be reconfigured and read out remotely and/or via the Internet using RFID, GSM or other wireless transmission technologies either automatically or by trained specialist staff.

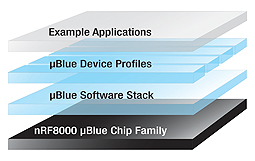

The use of RFID is always purposeful if only a few data must be transmitted exclusively upon request and if the wireless distance does not exceed a few centimetres. The new nRF8001 from Nordic Semiconductor is a suitable option if a device must function over a few meters or must initiate data transmission autonomously and still needs to function only with a button cell battery.

This 2.4GHz transceiver chip supports the new “Bluetooth low energy technology” standard and only requires an average current of a few µA. Even peak currents of 15mA can be provided by button cells. Soon, commercially available mobile phones, PDAs, laptops and tablet PCs will also support the new Bluetooth standard so that hardware developments can focus on the medical measuring units. This means more innovation at low cost. Cheaper consumer computers can serve as communication partners for medical devices. On the computer side, only an individual “App” (small software program) must be added.

Nordic Semiconductor have already made a name for themselves in the area of proprietary (non standardised) protocols in the 2.4GHz range, especially for applications that require extremely low energy consumption. For a number of years, applications in sports and wellness have used the Ultra Low Power ANT protocol, which has already been integrated into some Nordic transceivers. In view of the many years of experience with these technologies, Nokia and Nordic decided to work together to develop a new wireless standard for connecting devices to small computers, which is to require significantly less power than Bluetooth. Initially known under the name “Wibree”, later integrated by Bluetooth SIG as “Bluetooth low energy technology”, this protocol will create compatibility between devices with similar applications, offering the efficiency of similar proprietary solutions.

There are still major differences with regard to the question of which protocol to use for data transmission. Some manufacturers do not wish their products to communicate with competitor products and instead prefer using their own protocols or encrypted transmission using standard protocols. Other manufacturers wish to make their own products accessible for other devices, if possible, using Bluetooth for this purpose. In particular those favouring the latter strategy will in future change to the new Bluetooth low energy technology (µBlue) standard since, unlike the old Bluetooth standard, it neither requires data rates of several megabits per second nor 16000 frequency hops per second to achieve uninterrupted streaming. For time-uncritical transmission of measured values to data collectors, the customer will in future have a choice between ANT, Gazell and µBlue. Regardless of whether he chooses standards like Bluetooth or quasi-standards like ANT or Gazelle operated by a company and not by an organisation: All three protocols are very low-current, use the transceiver technology of the company Nordic Semiconductor and – like proprietary protocols – can be purchased via Rutronik. This means: Here, the customer always obtains the optimal solution for its requirements and its strategy.

Authors

Bernd Hantsche completed an apprenticeship as an IT engineer, after which he studied Electrical Engineering in Aachen, specialising in automation technology. After working as product manager at the Rutronik Wireless Competence Centre for three years, Bernd Hantsche was appointed as Product Area Manager for Wireless Technology in which position he has worked for two years being responsible for the marketing, which comprises application engineers and product specialists. He also assists customers in commercial and technical questions both on component and system level.

Tobias Mühlhäuser studied Electrical Engineering at the Cooperative University of Karlsruhe, specialising in communications engineering. As Product Manager at the Rutronik Wireless Competence Centre, he has been the specialist for RFID technologies and solutions since 2008.

www.rutronik.com