It’s installed like an ATX PSU, minimizing cabling to the chassis front

Box PCs are currently the most sought after compact IPC systems in the industrial sector, next to SFF (Small Form Factor) industry servers and Panel PCs. Their tasks are just as diverse as their variants. At Embedded World 2010 in Nuremberg, Kontron introduced a highly performance-scalable Box PC for installation in machines and control cabinets with both front- and rear-mounted interfaces as a serial product for smaller compact automation solutions. This eliminates the cost of the cabling from the IPC to the outer wall of the device chassis. In addition, it increases reliability by reducing the number of connectors and cables.

Due to the constantly increasing system performance of the new SFF processors, much smaller computer systems can now be built. At Embedded World, Kontron introduced the Kontron KIC (Kontron Intelligent Control) – a dual-access system in the “children’s shoebox” format offered for the first time as a compact standard system. Designed for installation in machines and control cabinets, the Kontron KIC Box PC is conceived for use in applications where, thanks to its minimized dimensions and energy consumption, the IPC is moved out of the 19-inch rack and into the machine itself. With its compact dimensions (200mm × 200mm × 86mm), comprehensive feature set, and particularly service-friendly mounting similar to an ATX PSU, the KIC impresses on many levels.

Solution for small automation tasks

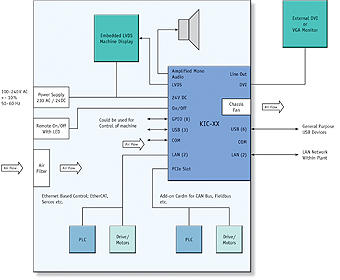

The above block diagram outlines a standard Kontron KIC application. The Box PC is positioned in the chassis of the automated system so that the communication interfaces for higher-level management and networking tasks, such as gigabit Ethernet, USB and serial interfaces are directly accessible from the outside. Thus, the cabling cost from the IPC to the outer wall of the chassis is eliminated. In addition, reliability is increased by reducing the number of connectors and cables. An additional monitor can be connected via DVI (or VGA, in some variations).

Similar to an ATX power supply, the integrated temperature-controlled fan blows warm air outwards. For small devices it can also regulate the heat dissipation of the entire chassis.

Communication with the control and fieldbus interfaces is implemented on the internal side of the dual access IPC. Due to the trend towards real-time Ethernet-based control systems, fieldbus interfaces have not been integrated. Internally there are two real-time Ethernet-enabled gigabit Ethernet interfaces. Through appropriate software protocols (EtherCAT, SERCOS), it can thereby integrate real-time capable and Ethernet-connectable control components into small automation systems. One PCIe x1 expansion slot for low profile PCIe add-on cards (e.g., CAN-bus) is available. Ports for the user interfaces, such as a chassis-integrated LVDS display, loudspeaker and the typical USB devices such as touch-screen, mouse or keyboard are also placed on the internal side.

The system is supplied with an automation industry standard 24V DC power supply. It provides control signals for switching the unit on and off and is flexible with respect to its mounting location in the chassis.

Alternative mounting possibilities

In addition to being mounted similarly to an ATX power supply in a 19″ rack system, the system can be mounted in virtually any way into cabinets. Vertical, horizontal as well as upwards-facing mounting orientations are possible. When mounted vertically the interfaces lie at the top and bottom, with the rear I/Os below and the front I/Os above. This ensures that airflow rises up from the base of the unit. When using low-power Intel Atom technology, fan-free operation is also possible. Furthermore, top hat rail mounting with interfaces positioned above and below is also possible. Thus, the system is suitable for installation in even the smallest of cabinets for, e.g., building automation.

Flexible performance

The Kontron KIC features high scalability thanks to implemented COM Express Computer-on-Modules from Kontron. The system is ready for both ETXexpress and microETXexpress modules as well and can therefore employ the particularly energy-efficient microETXexpress-SP module with Intel® Atom™ processors (Z510, Z530), the extremely cost-effective microETXexpress-DC module (Intel Atom N270, Intel 945GSE chipset), up to the ETXexpress-MC module with Intel® Core™ Duo CPU for very high computational requirements. Every new ETXexpress® Type 2 module can be integrated giving the KIC platform especially long-term security. The first version, the Kontron KIC-MC is equipped with an Kontron ETXexpress®-MC and offers up to 2 x 2.5″ hard disks with RAID-0 or RAID-1 functionality. The Kontron KIC system is currently also being readied for the microETXexpress-DC module. With this system design, the KIC-DC system can be operated completely fanlessly in a vertical orientation (interfaces above and below).

Kontron PicoClient-industrial mini panel PC with ARM9 processor

Panel PC for open human-machine interfaces

At Embedded World in Nuremberg, Kontron will introduce the new Kontron Pico Client Panel PC with 5.7″display, broadening its comprehensive Panel PC offerings, which currently extend up to multi-core based high-performance Panel PCs. The new Panel PC offers an exceptionally cost-effective and energy-efficient RISC-based solution for open HMIs and thin client operating concepts with, e.g., data storage on central (web) servers and visualizations on slim touch-panel clients.

Due to Jazelle implementation, the new industry-specific Kontron Pico Client panel PC with 200MHz/32Bit ARM9 features hardware-based JAVA acceleration, and thanks to its low power requirements it is especially attractive for mobile devices. For visualization and control tasks with network connections, there are two real-time-Ethernet-enabled 100 Mb interfaces implemented so that both vertical and horizontal networking topologies are possible.

This makes the fanless Kontron Pico Client the ideal human-machine interface (HMI) for networked machine-operated concepts as well as for building automation. For each USB and COM port (RS232 or RS485), one can also connect RFID or barcode readers, light curtains or other peripherals.

The rear-accessible SD memory card slot and backup battery are also very service friendly.

The Kontron Pico Client panel PC is cost-effectively packaged in a compact 212 mm × 156 mm plastic housing with 50 mm mounting depth that provides front-side IP65 protection. Power is supplied by 24 volt DC. Software support is offered for Windows CE.

Authors

Günter Dumsky, Director of Systems & Boards at Kontron

Dr. Roland Jäschke, Director of Custom Project Management at Kontron

www.kontron.com