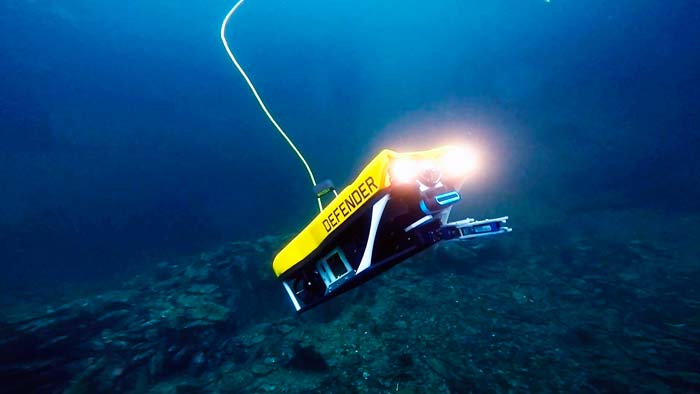

Figure 1 The VideoRay Defender, a remotely operated vehicle (ROV), requires a robust, high-density power delivery network (PDN) for powerful thrust to enable acute maneuverability under the most challenging conditions.

Port security and surveillance, mine countermeasures and underwater search and rescue are all dangerous missions that should no longer put lives or vessels at risk. Where sustained, mission critical underwater inspection or exploration is required, remotely operated vehicles (ROVs) are the safest and most effective way to maintain security, support salvage efforts and uncover secrets of the ocean.

Video-equipped ROVs can reach hard-to-access underwater locations at extreme depths for extended periods. To be effective, ROVs require a robust, high-density power delivery network (PDN) that enables the necessary thrust to withstand shifting ocean currents and provides a steady view of surroundings while having the space for payloads to accomplish mission-specific activities.

Video-equipped ROVs can reach hard-to-access underwater locations at extreme depths for extended periods. To be effective, ROVs require a robust, high-density power delivery network (PDN) that enables the necessary thrust to withstand shifting ocean currents and provides a steady view of surroundings while having the space for payloads to accomplish mission-specific activities.

VideoRay tethered underwater ROVs can be deployed for 24/7/365 operation at depths down to 305 meters (2000m in float mode), with power supplied from the host platform or vessel. Also in development is a battery-operated ROV that can sustain underwater operational uptime for up to 8 hours, and allows for a slimmer, lighter tether devoted purely for video and communications transmission.

Adapting to any mission

Among its many innovations, VideoRay offers an interchangeable, modular component ROV system residing on a single intelligent network. The system provides an extremely flexible and customizable platform that can be easily adapted to specific missions, markets and payloads.

VideoRay ROVs are designed to handle difficult missions that have size, weight, and deployment speed constraints. They are also distinguished by powerful thrust, longer tether lengths, higher resolution video, and interchangeable, modular systems.

Easily scaling for payloads and mission-specific protocols

To achieve advanced ROV capabilities, VideoRay requires a sophisticated power delivery network architecture that allows them to design ever-smaller ROVs with more power and greater maneuverability at greater depths. Among the many design factors at play is the modularity and power density of the onboard power components, key to enabling the VideoRay scalable ROV portfolio of providing the flexibility to swap high-performance modules to accommodate evolving requirements with the added agility to quickly and easily customize ROVs for customers.

VideoRay relies on Vicor to meet exacting requirements for power density, efficiency and low EMI noise in a manner that reduces the need for bulky heat sinking and EMI filter systems. This enables a sleek, power-dense system design that allows for efficient cooling while preserving valuable board space for other value-add componentry.

Figure 2: One VideoRay Control System feeds Vicor BCMs with rectified AC and connects their outputs in series to add up to a non-standard 72V tether voltage for short tethers. The supply and controller are housed in a small, portable pelican case so efficiency and density are important.

Delivering high-performance power for rugged missions

The highly modular VideoRay flagship Defender series ROVs have employed Vicor DCM™ series converters to produce lower-voltage power from 400VDC to energize all main thrusters and control electronics inside the subside vehicle. The DCM series of DC-DC converters is the ideal candidate for the Defender series due to its high power density in a small footprint that also integrates monitoring and auto-shutdown features The DCM series accommodates a wide input voltage range to allow for large voltage drops on longer tethers.

The high-efficiency, fixed-ratio Vicor BCM® bus converter used in the VideoRay Pro 4 Main Controller – (Figure 2), converts Rectified AC from the host ship to 72V DC in a compact fashion, delivered to the ROV via the tether to power it. It uses advanced heat sinking and active cooling for easy thermal management. High-voltage BCM modules in the to- side power converters help generate the tether voltage, with advanced heat sinking and active cooling for easy thermal management in a waterproof enclosure.

BCMs use the Vicor proprietary SAC ™ (Sine Amplitude Converter) topology, an extremely efficient resonant-tank based DC-DC converter architecture, to accomplish bidirectional fixed-ratio DC-DC conversion. With input voltage ranges from 36 to 800 volts and transforming voltage by various K factors to support a wide range of applications, some BCMs also feature integrated PMBus® telemetry, control and EMI filtering. BCMs are able to reach peak efficiencies of 98% with achieve power densities up to 2,400W/in³ and can have their inputs in parallel into high-power arrays and outputs connected in series and/or parallel to achieve even higher output voltages and/or currents than a single module.

For battery-powered ROVs, VideoRay is using Vicor high-power, high-density, 97% efficient PRM™ buck-boost converters with constant-current and constant-voltage control for battery management. Featuring a zero-voltage switching (ZVS) architecture, PRM buck-boost regulators accommodate a wide input voltage range and provide a regulated, adjustable output voltage.

VideoRay is leveraging Vicor power modules across its growing ROV portfolio in a manner that easily scales to meet evolving needs. Working together, VideoRay and Vicor have innovated a modular, high-density power delivery network architecture that enables VideoRay to develop smaller yet more powerful ROVs capable of operating continuously at great depths, with 24/7 run time.

Learn more about VideoRay’s ROV innovations.