Integrated IP-based Ethernet communication as well as data and power over ever-smaller cables and connectors to devices are all major challenges facing Integrated Industry. As work continues towards achieving this goal, HARTING is also advancing in the area of Single Pair Ethernet (SPE) and setting standards for the interfaces required. All relevant standardisation committees have now opted for the HARTING design of an SPE mating face. For the protocol, this is IEEE802.3, and for cabling it is ISO/IEC JTC 1/SC 25 and TIA 42.

A prerequisite for the widespread use and hence the successful marketing of SPE technology is the end-to-end compatibility of devices, cables and connectors. This is ensured by international standardisation (ISO/IEC and IEEE 802.3). The beginning of 2018 saw an internationally drafted selection process standardised via ISO/IEC for cabling and the selection of standardised SPE mating faces. TIA initiated a similar process in the summer of 2018, and in November 2018 the IEEE finally decided. All three major bodies came to the same conclusion:

- for building wiring, the mating face is standardised according to IEC 63171-1: this mating face is based on the proposal from CommScope and is known under the synonym Variant 1 (LC style) for M1I1C1E1 environments

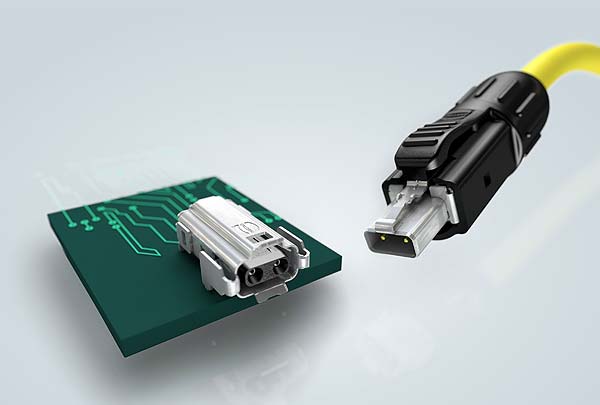

- for industrial and industry-related applications, the mating face is according to IEC 61076-3-125: this mating face is based on the HARTING proposal, is specially designed for use in up to M3I3C3E3 ambient conditions and is known as Variant 2 (industrial style). This SPE connector concept can handle 1GBit/s for shorter distances as well as 10Mbps for long distances (1000m and longer) with a mutually compatible mating face and is available in IP20 to IP65/67.

The development towards ever smaller and more powerful devices is making inroads into automation. Despite higher data rates and the parallel transmission of power (remote power supply), cabling components must become smaller and lighter. The new Single Pair Ethernet technology SPE, which is based on transmission standards according to IEEE 802.3bp and 802.3cg, now enables data transmission over Ethernet via a single pair as well as simultaneous power supply to end devices via PoDL – Power over Data Line. Two pairs have hitherto been required for Fast Ethernet (100MB) and four pairs for Gigabit Ethernet. There is now a push to leverage the advantages of SPE in industrial automation as well. Here, SPE enables the barrier-free connection of devices and sensor/actuator technology via integrated IP-based communication right down to the field level. Equipping simple sensors, cameras, or reading and identification devices with Ethernet interfaces supports the implementation of Integrated Industry and IIoT.

Here, SPE delivers the decisive difference to bus systems or power interfaces in the form the latter are still to be found today at the field level. The field level thus becomes “smart”, and the integrated Ethernet communication reduces the effort involved in parameterisation, initialisation and programming. At the same time, all elements in the automation network can be set up, monitored and controlled remotely. The construction, operation and maintenance of equipment become more efficient and cheaper.

Many connected devices, switches, sensors and other consumers do not require additional power supplies or batteries. This increases operational safety and protects the environment.

HARTING Technology | www.HARTING.com