Many years ago, power-distribution strategies in data centers and telecom offices used multiple isolated full, half-, quarter- or eighth-brick converters to transform the 48VDC bus voltage typically used in telecom, down to the required on-board integrated circuit (IC) supply voltages. However, the 1990s brought in the concept of the distributed power architecture, which further evolved to include the introduction of the intermediate bus. Primarily designed to save the cost and bulk of multiple isolated converters, the architecture comprises an AC-DC front-end power supply, an isolated Intermediate Bus Converter (IBC) usually of an industry-standard size such as a quarter brick or one-eighth brick, and on-board non-isolated Point-of-Load (POL) converters.

Many years ago, power-distribution strategies in data centers and telecom offices used multiple isolated full, half-, quarter- or eighth-brick converters to transform the 48VDC bus voltage typically used in telecom, down to the required on-board integrated circuit (IC) supply voltages. However, the 1990s brought in the concept of the distributed power architecture, which further evolved to include the introduction of the intermediate bus. Primarily designed to save the cost and bulk of multiple isolated converters, the architecture comprises an AC-DC front-end power supply, an isolated Intermediate Bus Converter (IBC) usually of an industry-standard size such as a quarter brick or one-eighth brick, and on-board non-isolated Point-of-Load (POL) converters.

To optimize transient response, these POLs are positioned close to the power pins of devices such as processors, FPGAs/ASICs, memory and other ICs. In this architecture, the IBC down-converts the nominal 48VDC from the front-end power supply to a 12VDC rail that is distributed to the non-isolated POL converters, which convert the 12V input into regulated voltages as required by on-board ICs. These typically can range to below 1V as needed to power processor or FPGA core logic. In addition, the use of ever more advanced IBC modules provided a continual size and cost reduction with the gradual move from one-quarter to one-eighth to one-sixteenth standard-sized modules.

Increasing Traffic and Power

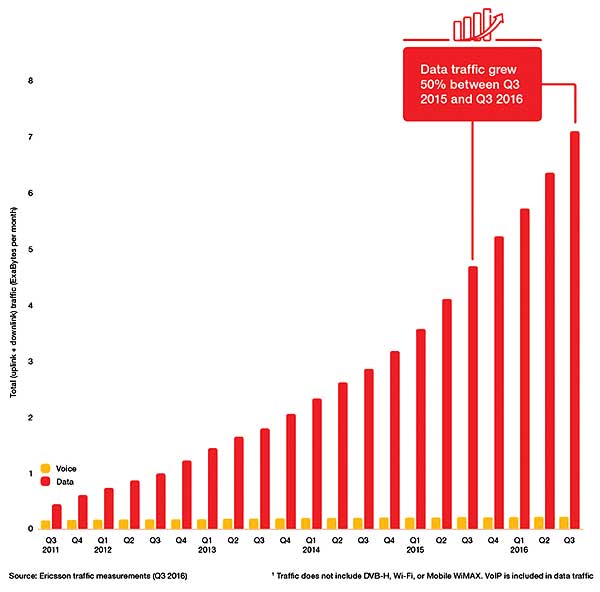

The amount of data transferred through networks is increasing significantly thanks in part to the continued growth in mobile traffic. According to the latest Ericsson Mobility Report, mobile data traffic alone increased by 50 percent from Q3 2015 to Q3 2016 (see Figure 1). This growth in data traffic is being driven by increasing numbers of smartphone subscriptions and a continued rise in average data use per subscription, fueled primarily by consumption of video content. Between 2016 and 2022, smartphone traffic is expected to see a 10-fold rise, while total mobile traffic for all devices is forecast to increase to eight times its current level.

Data centers and telecom offices are therefore coming under enormous pressure to support the ever-increasing numbers of subscribers and connections, while delivering increasingly data-intensive services with minimal latency. This has meant that the peak power consumption of large motherboards has risen significantly above 1kW and is likely to push well beyond 3kW in the coming years. As power consumption continues to rise, efficiency is a growing focus for data center operators who are seeking to control the spiraling power costs of servers and cooling systems, and minimize their overall enterprise environmental footprint. Energy prices can be expected to rise, meaning the cost to power a large-scale data center could soon be greater than the cost of servers and networking equipment.

Advantages of Direct Conversion

The latest advanced converters are capable of offering typical efficiencies of 95-96% for an IBC and 90% for a 12V-1V POL at a particular load. However, cumulative energy loss from both stages of conversion can reduce the overall efficiency to approximately 86.4%. The alternative is to use a single converter to produce the required IC supply voltage with an efficiency of 89% or above, for the same load, thereby increasing overall conversion efficiency (see Figure 2).

Another factor to consider is the reduction in I2R distribution losses. The distribution of 48V DC for direct conversion at the point of load means that the bus supplying the converter carries just 25% of the current that would be required to deliver the same level of power at 12V. This four-fold decrease means I2R distribution losses from the 48V source can be cut by a factor of 16.

Additionally, there is also a reduction in the amount of copper required by the distribution of power. The reduction in I2R distribution losses will become increasingly important as total server power continues to rise.

A third benefit is the saving of board real estate and reduction in the cost of materials, electronics assembly and manufacturing. Based on the latest technologies, a new direct 48V-to-POL converter can be smaller in size than comparable conventional modules in quarter or eighth-brick sizes along with POL converters. It can also eliminate the need for high-current multiple and parallel IBC quarter-bricks or eighth-bricks.

However, for highly complex or high-power systems, you will still probably need for a reduced-power intermediate bus to power low-current rails. But again, you’ll likely require an eighth- or a sixteenth brick- rather than a quarter-brick IBC converter will likely be required, thereby saving additional board space.

Single-Stage Conversion

The adoption of direct conversion, implemented using the latest power technologies, is a growing trend in telecom and datacom markets. Today, a new generation of highly compact and efficient single-stage converters which will directly convert from 48V down to logic, is being developed. These devices will be capable of supporting the low duty cycles required to convert from 48V to 1.0V, while operating at a high switching frequency to ensure fast transient response and minimize reliance on decoupling capacitance and magnetic components. Progress within the industry continues on with the development of advanced scalable solutions.

Direct conversion solutions will not replace existing power distribution schemes overnight. New devices will enter into the market alongside the IBC and POL products currently used to power boards from a few hundred watts up to 3kW or higher. The expectation is that direct conversion will deliver the greatest efficiency gains in equipment at higher power levels. It can be used to dramatically reduce loads in IBCs, for example, thereby enabling designers to create smaller units and possibly even enabling the use of eighth-brick or sixteenth-brick modules rather than quarter-brick ones. This will be ideal for next-generation high-current processors.

However, cost or legacy issues may determine the point at which some equipment manufacturers consider implementing direct conversion. The availability of direct-conversion and traditional modules, side-by-side in the market, will provide designers with the freedom to come up with hybrid architectures that combine Intermediate Bus and Direct Conversion topologies to deliver the best of both worlds.

Summary

Distributing higher voltages, such as 48VDC, on motherboards and converting directly to required POL voltages brings a number of advantages. These include higher efficiency, lower I2R distribution losses, as well as freeing up board space that would otherwise be required by an intermediate converter.

In practice, cost pressure, combined with engineering constraints on switching frequency, step-down ratio and transient performance, have historically meant the use of the now traditional two-stage topology to convert from a 48VDC input down to IC supply voltages. But with the growing need to maximize energy efficiency and dramatically increase power density, by drawing on the latest power technologies, direct conversion solutions can offer highly efficient power-conversion architecture as well as board-space savings.

[1] Ericsson Mobility Report www.ericsson.com/mobility-report

By Bob Cantrell, Senior Application Engineer at Ericsson Power Modules

Ericsson Power Modules

www.ericsson.com