Soldering, a technique that originated in ancient Egypt, is indispensable in electronics production today. Despite all the progress made, defects can still occur, which can lead to unreliable solder connections and thus to malfunctions or even failure of the end product. It is therefore important to know the causes of soldering defects so that preventive action can be taken. With our expertise in soldering technology, we have been supporting our customers for over 30 years with all questions and problems in the field of reflow soldering and provide an overview of some of the causes of tombstones.

Soldering has a long history dating back to ancient Egypt. Today, it plays an indispensable role in the manufacture of electronics, among other things. Despite numerous developments in soldering technology, soldering defects can still occur, resulting in electronic components not being reliably connected.

Such a faulty solder connection means that the circuit is not reliably closed, which can lead to malfunctions and even failure of the end product. In addition, defective connections can result in high electrical resistance and thus increased heat generation, which can damage the components or cause fires.

Unreliable end products and safety issues: they damage a company’s reputation and customer confidence in the brand. Manufacturers therefore endeavour to identify soldering defects during the production process and to sort out or repair faulty PCBs, although this is associated with significantly higher costs.

In addition, the probability of soldering defects can also be reduced before and during the soldering process: some causes of are shown below.

Tombstones

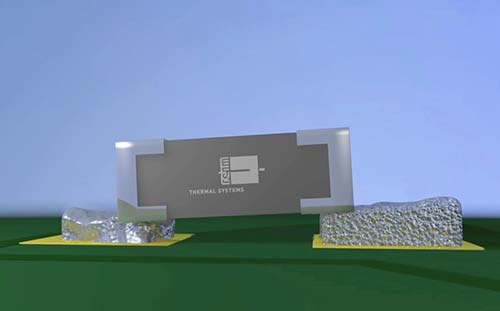

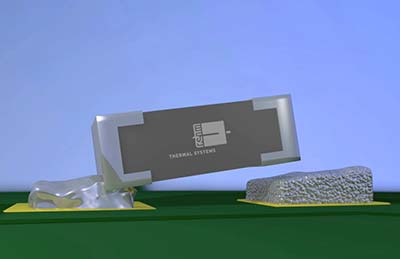

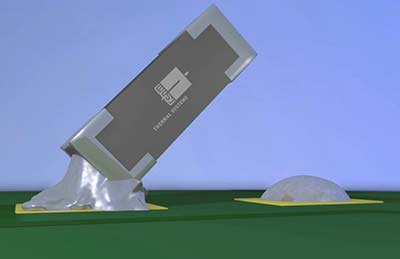

Tombstones occur as soon as one solder joint of two-pole components (e.g. capacitors or resistors) melts before the other. If this is the case, the wetting forces and the surface tension cause the element to lift on one side (see Bell et al. 2021: 94). “An adequately large imbalance of forces between the component’s weight force and the wetting forces which act upon it, as well as surface tension, is a prerequisite for the occurrence of tombstones” (Bell et al. 2021: 95). This leads to the assumption that with a solder paste with a lower surface tension, the weight force of the component is sufficient to hold it in position and, as a result, the occurrence of tombstones can be reduced.

In contrast, however, lead-free solders have a higher surface tension and lower tombstone rates (see Bell et al. 2021: 95). Instead, the results of several studies (see also Nowottnick & Trodler 2010: 153ff.) speak in favour of a correlation between increasing wetting time and decreasing tombstone rates (see Bell et al. 2021: 96-99).

To counteract the asynchronous melting of solder joints and thus the formation of tombstones, larger quantity differences between the pastes of both connection pads can be prevented, as the smaller one always melts before the larger solder deposit (see Bell et al. 2021: 100f.).

Paste deposit at right is melted but is no longer able to reach the connector. (Pictures: Rehm Thermal Systems)

The conveyor speed can also counteract the tombstone effect. The higher the speed, the greater the risk that the soldering material is not heated through evenly and that one solder joint melts earlier than the other (see Bell et al. 2021: 101f.).

The soldering profile also influences tombstone formation: depending on the solder paste formulation, the PCB design as well as printing and placement tolerances, tombstones can occur in both linear and saddle-shaped profiles. If pads have a ground connection, more copper layers in the vicinity, vias, etc., the solder paste tends to melt later due to the greater thermal mass (see Bell et al. 2021: 102f.). To counteract this effect, the saddle profile can be advantageous because it homogenises the temperature distribution in the assembly through the holding phase.

Curious?

The technology manuals from Rehm Thermal Systems deal with many other exciting topics relating to reflow soldering: take a closer look at the reliability of soft solder joints and other soldering defects or immerse yourself in the technology and engineering of soft soldering. Find out what effects reflow profiles have on the soldering process and the soldering result, and what about bottom termination components and migration. You can order the volumes by e-mail: sales@rehm-group.com

Do you have questions on a specific topic?

We advise our customers and interested parties on all technological issues and provide support in selecting the right production process and associated parameters. Our employees in the Technology Centre will be happy to help you: applikation@rehm-group.com

References

Bell, H., Grossmann, G. & Wohlrabe, H. (2021). Reflow Technology. Fundamentals of Reflow Soldering. Part 3: Reliability and Failure Management (3rd ed.). Rehm Thermal Systems GmbH.

Nowottnick, M. & Trodler J. (2010). Silberreduzierte Weichlote auf Basis SnAgCu. Jahrbuch Mikroverbindungstechnik 2009/2010. Universität Rostock, Fakultät für Informatik und Elektrotechnik (IEF).