TE Connectivity (TE), a world leader in connectivity and sensors, is launching the D-2970 Dynamic Series compact wire-to-board PCB connector with field-installable, time-saving push-in clamp termination.

TE Connectivity (TE), a world leader in connectivity and sensors, is launching the D-2970 Dynamic Series compact wire-to-board PCB connector with field-installable, time-saving push-in clamp termination.

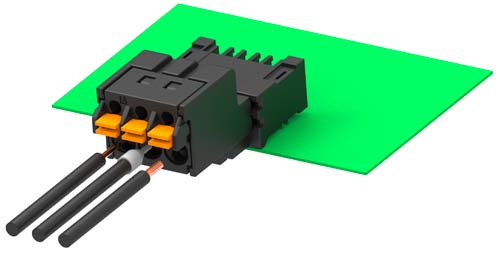

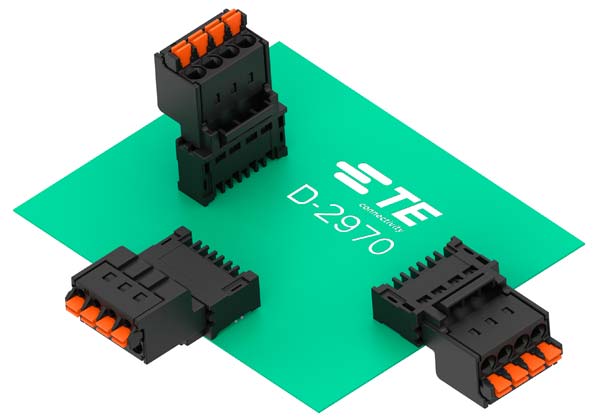

TE Connectivity launches D2970 Dynamic Flex Push-In pluggable PCB connectors. — Source: TE Connectivity, PR404

The new 5mm pitch PCB connector operates at up to 20 amps and 400 volts at a typical ambient application temperature of 55°C without further derating. It incorporates numerous features to meet strict safety requirements. These include an audible and tactile locking latch to ensure safe mating, a robust housing, contacts that support shock- and vibration-exposed applications, and an IP20 “finger safe” housing that prevents unintended operator contact with live components. The D-2970 also meets the IEC EN 61800-5 standard for adjustable speed electrical power drive systems.

The push-in clamp and single-hand-operating center-locking lever – both designed to require no tooling – make it possible to cut mating time by up to 90% compared with connectors using screw-latch locking systems. The center-locking lever has clear tactile and audible mating feedback. Toolless wire release is also possible, thanks to the 50% lower insertion force, which allows users to release the wire without injuring their fingertips.

The D-2970 is available with three different angled male headers, all mating with the same female plug, providing electronics designers flexibility. The initial configuration has three or four positions, which will be extended with versions with anywhere from two to 12 positions during 2020.

“This new PCB connector family is a powerful addition to our well-known Dynamic Series and is fully equipped to meet our customers’ high standards regarding installation and application safety, also saving valuable process time and application space,” says Product Manager Christian Netsch.

The D-2970 will be fully compliant with UL and IEC regulations and extensively tested at UL and VDE certified laboratories, supporting customer approval processes. It uses materials that conform with regulatory requirements such as RohS and Reach, and which obtain a V-0 rating under the UL 94 flammability standard while remaining low-halogen according to IEC EN 61249-2 (the male housing is injection molded in LCP and the female housing is in PBT). It also meets the IEC EN 60335-1 standard for domestic home appliances.

“We can describe the goals of our development of this new connector series in two words: safety and efficiency,” says Netsch. “The mechanical design, as well as the chemical base of the housing materials, protects installers and operators and allow a very time-efficient wire installation and space-saving PCB design – finally saving cost for our customers.”

Netsch further points out that the strong locking latch allows a small form factor with a header height of under 9mm. “Compared to other PCB connectors with locking features in the market, the D-2970 Series can save valuable space within the cabinet,” he notes. “It provides a width-saving up to 26% for a two-pole connector or 13% for a six-pole connector compared with connectors using side locking. This allows a side-stackable PCB mounting of several headers next to each other.”

Manufacturing efficiency

D-2970 Dynamic Flex Push-In headers are through-hole reflow capable. They are available without the need for a pickup cap, saving waste and are offered in box packaging. Tape and reel packaging is available by request. The header resin is MSL 1 (Moisture Sensitivity Level) compliant, which prevents the soldering component from absorbing any water during shipment, storage and manufacturing, even in high humidity environments. This allows a floor and storage life of at least two years.

TE Connectivity expects the Dynamic Series D-2970 Push-In PCB connectors to be used in diverse applications, including power inlets and outlets for PLCs and servo/inverter drives, industrial micro controls, robot control units, and controls in building automation and household appliances. The parts will be available directly from TE Connectivity as well as many distribution partners around the globe beginning in December 2019.