Siemens Digital Industries Software today announced it has collaborated with leading Outsourced Assembly and Test (OSAT) company Siliconware Precision Industries Co., Ltd. (SPIL) to develop and implement a new integrated circuit (IC) package assembly planning and 3D layout vs. schematic (LVS) assembly verification workflow for SPIL’s fan-out family of advanced IC packaging technologies. SPIL plans to deploy this differentiated capability across its 2.5D and fan-out package family technologies.

Siemens Digital Industries Software today announced it has collaborated with leading Outsourced Assembly and Test (OSAT) company Siliconware Precision Industries Co., Ltd. (SPIL) to develop and implement a new integrated circuit (IC) package assembly planning and 3D layout vs. schematic (LVS) assembly verification workflow for SPIL’s fan-out family of advanced IC packaging technologies. SPIL plans to deploy this differentiated capability across its 2.5D and fan-out package family technologies.

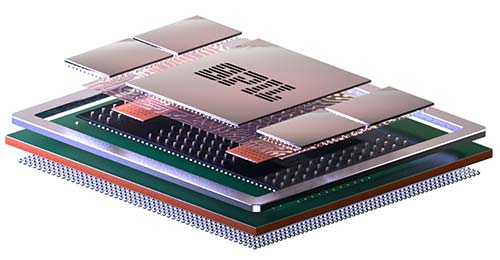

To meet ongoing global demand for ICs that deliver more performance and lower power consumption within ever smaller footprints, IC designs increasingly feature sophisticated packaging techniques such as 2.5D and 3D configurations. These techniques combine one or more ICs of different functionality with increased I/O and circuit density, which in turn requires the ability to create and review multiple assemblies and LVS, connectivity, geometry and component spacing scenarios. To help customers overcome challenges associated with deploying these advanced packaging technologies, SPIL selected Siemens’ Xpedition™ Substrate Integrator software and Calibre® 3DSTACK software for package planning and 3D package assembly verification LVS for its advanced fanout family of package technologies.

“Our challenge was to develop and deploy a proven advanced packaging assembly planning and verification workflow that included comprehensive 3D LVS,” said Dr. Yu Po Wang, vice president of CRD for Siliconware Precision Industries. “Siemens are a recognized leader in this space with a robust and proven workflow that we will use in production to validate our fan-out family of technologies.”

SPIL’s fan-out packaging family offers additional space for routing a higher number of I/O on top of the semiconductor’s area and extending the package size with a fan-out process, which cannot be achieved with conventional advanced packaging technologies.

“Siemens is pleased to collaborate with SPIL to define and deliver the workflow and technologies needed for their advanced packaging technologies,” said AJ Incorvaia, senior vice president of Electronic Board Systems at Siemens Digital Industries Software. “As SPIL’s customers continue to develop higher complexity designs, SPIL and Siemens stand ready to deliver the advanced workflows needed to bring these increasingly sophisticated designs to market.”

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.