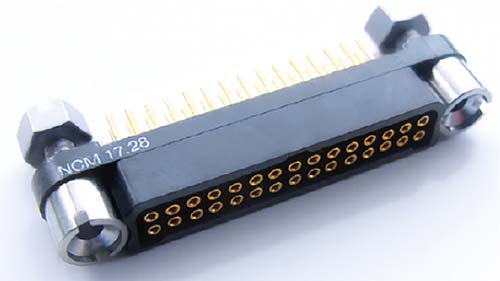

Nicomatic SA, the leading manufacturer of high-performance interconnect systems, has announced new features for its rugged micro connector, the 1.27 mm pitch EMM series, which targets defense and other high-reliability applications. The MIL 83513-style connectors that require a significantly smaller footprint than the closest industry competitor now feature captive screw fixings and can be used with thicker PCBs and larger diameter cables.

Nicomatic SA, the leading manufacturer of high-performance interconnect systems, has announced new features for its rugged micro connector, the 1.27 mm pitch EMM series, which targets defense and other high-reliability applications. The MIL 83513-style connectors that require a significantly smaller footprint than the closest industry competitor now feature captive screw fixings and can be used with thicker PCBs and larger diameter cables.

Captive screw fixings provide the fastest locking solution available, since there is no need to tighten alternative sides repeatedly. They also ensure that screws are never lost. EMM miniature connectors are also now optionally available with longer straight-through and 90° contacts enabling them to be used on PCBs that are up to 3.5mm thick. Finally, EMM connectors can also be used with AWG24 cable, larger than competing devices.

Suited for both board-to-board and board-to-wire (from awg 24 to 30) applications, EMM connectors are available with any pin selection from 04 to 60 signal contacts. Signal contacts are rated for up to 3A, and deliver a wiping length of 1.27mm with 1.27µm gold plating to ensure that signal integrity is maintained while under conditions of heavy shock and vibration. Devices are rated for up to 45 G vibration, exceeding EIA 364-28E test conditions III&IV, up to 160 G for shock, exceeding EIA 364-27B G, and for an operational temperature range of -65 to +260°C exceeding EIA 364-32D.

Innovative design features such as reversed contacts, integrated 90° back protection and interchangeable hardware, ensures that the new EMM connector series combines rugged design with enhanced electrical and environmental performance.

More, Nicomatic uses modular manufacturing technology, so all configurations are available on very quick turn-around. Cabled versions can be assembled at Nicomatic, or by the customer.