The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, is introducing THERM-A-GAP™ GEL 120, a one-component, dispensable, thermal interface material with a very high thermal conductivity performance. The 12.0 W/m-K thermal conductivity of this advanced product can overcome challenging heat dissipation issues and provide greater design flexibility as engineers look to meet the demanding performance expectations of end users.

Features

The special formulation of this innovative gel reduces thermal junction temperatures and effectively conducts heat away from heat-generating electronic components. As a filler material it is ideal for use in air gaps of various thicknesses created by assembly and manufacturing tolerances or rough surfaces, from less than 0.5 mm up to 4 mm. Such gaps are common between components or PCBs and heat sinks, metal enclosures and chassis.

As a one-component, fully cured material, THERM-A-GAP GEL 120 does not require any secondary curing or additional processes to achieve its specified physical or thermal properties.

The gel needs very low compressive force to conform under assembly pressure, placing minimal stress on electronic components, solder joints and leads in applications that include telecommunications equipment, consumer devices, mission-critical electronics, energy storage devices and automotive control units and sensors. Essentially any electronic applications where heat dissipation is critical.

High performance and reliability

As with all thermal gels from Parker Chomerics, the formulation of THERM-A-GAP GEL 120 accommodates the high performance and reliability needs of modern electronics. The product can operate in temperatures from -50°C to +200°C.

As with all thermal gels from Parker Chomerics, the formulation of THERM-A-GAP GEL 120 accommodates the high performance and reliability needs of modern electronics. The product can operate in temperatures from -50°C to +200°C.

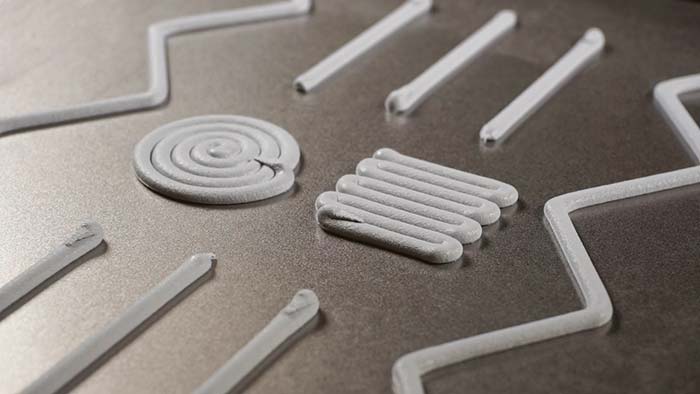

To support rapid application, this versatile and reworkable product is ideal for use with robotic dispensing machines and automated assembly processes. The flow rate of THERM-A-GAP GEL 120 is 25 g/min (30 cc syringe with no tip, 2.5 mm orifice, 621 kPa). Users enjoy very closely controlled dispensing and precise material placement, leading to high repeatability and greater throughput.

Designed to meet a growing need for interface materials with high conductivity and greater conformability (for easier application), the supporting electrical properties of this RoHS-compliant product include: 5 kVac/mm dielectric strength (ASTM D149 test method); 1013 Ωcm volume resistivity (ASTM D257); 5.7 dielectric constant at 1,000 KHz/2 mm thick (ASTM D150); and 0.013 dissipation factor at 1,000 kHz/2 mm thick (Chomerics test method).

THERM-A-GAP GEL 120 is available in syringe, plastic cartridge, EFD plastic cartridge, aluminium cartridge and pail containers, offering standard fill volumes from 10 to 2500 cc.

Learn more about THERM-A-GAP GEL 120 here: THERM-A-GAP GEL 120.