Indium Corporation has expanded its flux portfolio with a robust flux designed to provide a simple solution to complicated applications, especially those with a single cleaning step for both BGA ball-attach and flip-chip processes.

Indium Corporation has expanded its flux portfolio with a robust flux designed to provide a simple solution to complicated applications, especially those with a single cleaning step for both BGA ball-attach and flip-chip processes.

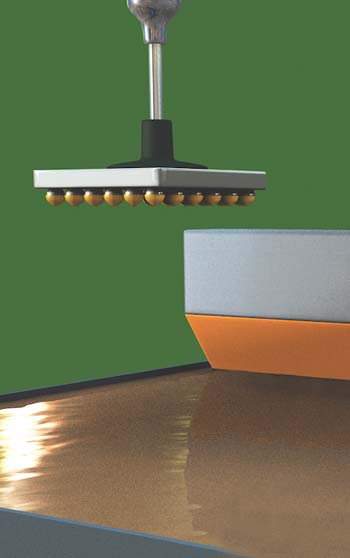

WS-446HF is a water-soluble, halogen-free, flip-chip dipping flux with an activator system powerful enough to promote good wetting on the most demanding surfaces—including solder-on-pad (SoP), Cu-OSP, ENIG, embedded trace substrates (ETS), and flip-chip on leadframe applications.

WS-446HF:

- Includes a chemistry that eliminates dendrite issues, especially critical for fine-pitch flip-chip applications

- Provides tackiness suitable for holding solder spheres and large die in place during assembly, eliminating missing balls and reducing die tilt and non-wet-opens due to warpage

- Delivers consistent pin transfer, printing, and dipping performance, ensuring consistent joint quality and improving production yields

- Eliminates the need for multiple fluxing steps, enabling a single-step ball-attach process and eliminating the warpage-inducing effects of prefluxing

- Has good cleanability with room temperature DI water, avoiding the formation of white residue

Indium Corporation is a premier materials manufacturer and supplier to the global electronics, semiconductor, thin-film, and thermal management markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, the company has global technical support and factories located in China, India, Malaysia, Singapore, South Korea, the United Kingdom, and the USA.