Most standard Computer-on-Modules use SO-DIMM connectors to integrate the main memory. Since the main memory is often customized for the specific application, this modular approach works well for module manufacturers and their OEM customers. However, the resistance of such connectors to shock and vibration is limited. Although lever arm and mass are not so large, even comparatively small vibrations can impair the functional reliability of the RAM when standard memory modules are used. Applications exposed to high shock and vibrations therefore require more robust designs.

Most standard Computer-on-Modules use SO-DIMM connectors to integrate the main memory. Since the main memory is often customized for the specific application, this modular approach works well for module manufacturers and their OEM customers. However, the resistance of such connectors to shock and vibration is limited. Although lever arm and mass are not so large, even comparatively small vibrations can impair the functional reliability of the RAM when standard memory modules are used. Applications exposed to high shock and vibrations therefore require more robust designs.

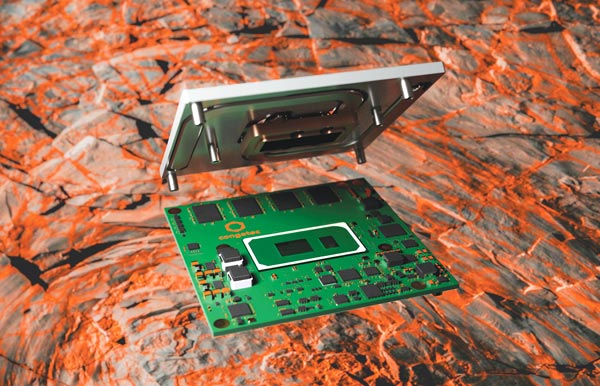

congatec COM Express modules with 11th generation Intel Core processors are predestined for harsh environmental conditions ▶

In the rail cargo sector, for example, vibrations of around 0.002 g²/Hz at frequencies from 0 to 350 Hz are common. Vibration levels experienced in jet aircraft are significantly higher at 0.01 g²/Hz with frequencies up to 2000 Hz. For systems deployed in trucks, levels even reach up to 0.02 g²/Hz. And turbine engines, such as those used in wind turbines, pose higher demands still, stressing components with up to 0.03 g²/Hz.

Soldered memory – rugged and cost efficient

Developers of such and many other mobile and stationary automation systems exposed to shock and vibration are therefore looking for better solutions to connect the main memory. For instance, memory manufacturers have added screw holes at the far end of their SO-DIMMs to attach the RAM modules securely so that shock and vibration are no longer a problem.

But such technology does not have many takers that is why rugged SO-DIMMs with mounting holes have been mass-produced, which makes them more expensive. In addition, they are also more complex mechanically and hence more expensive to assemble. Lastly, they also require additional mounting holes on the boards, which further increases production costs. The best solution therefore is to avoid all these add-ons and simply solder the memory directly onto the module. This reduces the bill of materials for components, makes production more cost-effective and, most importantly, ensures ruggedness. And there is yet another distinct advantage of soldered memory: Cooling is easier than with conventional memory connectors. First, because the PCB on which it is soldered has better heat dissipation, and second, because the heat sinks of rugged Computer-on-Modules are specially designed for the respective ruggedness requirements and can be equipped with a heat-conducting connection for cooling hot spots such as the main memory.

Rugged COM Express Type 6 Computer-on-Modules

congatec recently introduced new Computer-on-Module solutions based on the very latest 11th generation Intel Core processors with soldered RAM. These COM Express Type 6 Computer-on-Modules comply with the ETSI EN 300 019-1-7 and IEC 60721-3-7 specifications for portable and non-stationary telecom equipment and have been tested for commercial 7K3, 7M2 and industrial 7K4, 7M2 environments. This class also applies to non-weather protected locations in moderate outdoor climates and transfers between these conditions. For example, where equipment may be exposed to direct sunlight, radiant heat, ambient air movement, condensation, precipitation, and water from sources other than rain and ice.

Meets all relevant standards

In terms of shock and vibration, these modules are suitable for use in demanding transport and mobility applications up to offroad and rail vehicles. In addition they can withstand continuous operation in extreme temperatures (-40°C to +85°C), high humidity and heavy mechanical stress due to shocks and vibrations and meet all requirements for fire protection. Typical customers for the new range of Computer-on-Modules based on the Tiger Lake microarchitecture are OEMs of trains, commercial vehicles, construction equipment, agricultural vehicles, self-driving robots and many other mobile applications in demanding outdoor and off-road environments. Shock and vibration resistant stationary devices are another important application area as digitization requires critical infrastructure protection (CIP) against earthquakes and other mission-critical events. All these applications can now benefit from super-fast LPDDR4X RAM with up to 4266 MT/s, which congatec offers in graded versions with 32, 16, 8 and 4 GB as standard variants. Depending on the requirements, the highest-performance modules can also be equipped with smaller memory or lower-performance variants based on the Intel Core i3-1115G4E with more than 8 GB RAM. In-band error correction code (IBECC) for single failure tolerance and high data transmission quality in EMI-critical environments corroborate the ruggedness of the modules.

Comprehensive development support for ultra-rugged systems

The value package also includes rugged mounting options for the COM and carrier bundle, active and passive cooling options, optional conformal coating for protection against corrosion from moisture or condensation as well as sulfur protection, a list of recommended carrier board layouts and – for maximum reliability – shock and vibration resistant components for the extended temperature range. This impressive technical feature set is complemented by a comprehensive service offering that includes shock and vibration testing for custom system designs, temperature screening and high-speed signal compliance testing, as well as design-in services and all necessary training to simplify the use of congatec’s embedded computer technologies.

![]()

About the author

Zeljko Loncaric, is Marketing Engineer at congatec.