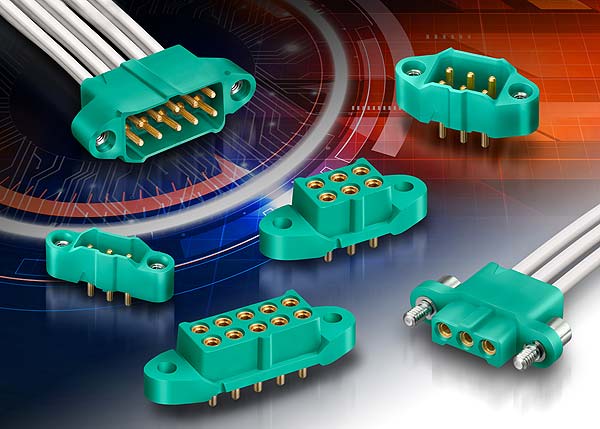

In keeping with the company’s core objective of providing elevated levels of performance in the most compact of components, Harwin’s expansive M300 family comprises robust cable-to-board, board-to-board and cable-to-cable power connectors. Available in 3, 6 and 10 contact formats, these units can be accompanied by a variety of cable assembly options (with lengths from 150mm to 450mm supplied).

In keeping with the company’s core objective of providing elevated levels of performance in the most compact of components, Harwin’s expansive M300 family comprises robust cable-to-board, board-to-board and cable-to-cable power connectors. Available in 3, 6 and 10 contact formats, these units can be accompanied by a variety of cable assembly options (with lengths from 150mm to 450mm supplied).

Thanks to the patented 4-finger contact design employed, which relies on a Beryllium Copper alloy construction, connection integrity is always maintained – even when these connectors are subjected to high degrees of shock, vibration, or other forms of mechanical stress. Despite their limited dimensions, the narrow pitch connectors have a 10A current rating, and are therefore very well optimized for use in systems where the performance expectations are exacting, but space constraints also need to be contended with.

A combination of stainless steel jackscrews ensure secure mating. Consequently, the connectors have a mating cycle durability of 1000 mates/un-mates. A series of polarization mechanisms are also incorporated to prevent mis-mating occurring, plus the recessed ‘scoop-proof’ female contacts and shrouded housing arrangement for the male contacts help protect them from sources of potential damage. Furthermore, a back potted rear aids cable retention.

Halogen-free and RoHS compliant, the Harwin M300 offering is predominantly aimed at motorsport, defense, factory automation, satellite, robotics, renewable energy and avionics deployments. An extensive working temperature range is supported (spanning from -65°C to 175°C) and low outgassing properties are of major benefit if these connectors are deployed within a vacuum.

“With available board real estate often at a premium, engineers need access to high performance technology that can be implemented within extremely confined spaces,” states Giorgio Potenza, Strategic Market Manager for Avionics, Defense & Space at Harwin. “Through our M300 connector products, power can be delivered while simultaneously keeping overall component size and weight low, with the accompanying cable assemblies adding an extra dimension of convenience.”

Harwin | www.harwin.com