In addition to the professional field, the therapy sector is also steadily increasing in importance. Particularly interesting in this context is what is referred to as “mobile health”. Constant cost pressure on the health insurance funds means that stays in hospital as an inpatient should as far as possible be minimized, and that means remote treatment and therapy in the patient’s own home, homecare, are becoming more and more significant. For electrical devices in the medical technology sector, however, use in the private environment means that conditions and regulations are becoming more stringent, too. Portable devices with direct mains connection must, according to IEC/EN60601-1, always be designed in protection class II, and, if appropriate, also in BF. The below should clarify these terms in greater detail.

In addition to the professional field, the therapy sector is also steadily increasing in importance. Particularly interesting in this context is what is referred to as “mobile health”. Constant cost pressure on the health insurance funds means that stays in hospital as an inpatient should as far as possible be minimized, and that means remote treatment and therapy in the patient’s own home, homecare, are becoming more and more significant. For electrical devices in the medical technology sector, however, use in the private environment means that conditions and regulations are becoming more stringent, too. Portable devices with direct mains connection must, according to IEC/EN60601-1, always be designed in protection class II, and, if appropriate, also in BF. The below should clarify these terms in greater detail.

Electrical safety with power supply units relates essentially to protection against electric shock. In this context, depending on the application, there are a number of different Standards to be applied. To ensure electrical safety for power supply units, there are two Standards which are relevant. On the one hand, there are IEC/EN60950-1 and IEC/EN60601-1. At this point, too, the IEC/EN 60335-1 (“Household and similar electrical appliances”) should be mentioned, which is sandwiched between the two other Standards referred to. Both of them serve the same purpose, but only one can be applied to medical technology. IEC/EN60601-1 differentiates between devices with direct and indirect patient contact, and a distinction is drawn between three classes: B (Non-Patient Contact), BF (Body Floating), and CF (Cardiac Floating).

RACM40_65: Ideally suited for medical technology – no derating with housing thanks to convection and contact cooling – and ambient temperatures of up to 80°C

Class B is suited for general medical applications, and therefore only for MOOP (Means of Operator Protection). This means medical personnel, or even members of the general public, who operate the device in a healthy state. A comparison in this case would be a PC which is approved in accordance with IEC/EN60950 (and likewise the external power supply unit which supplies it) and which is therefore in direct contact with the user, but a healthy user, and therefore, on the basis of use in the office or IT environment, is likewise “only” approved in accordance with IEC/EN60950. The much more stringent Classes BF and CF describe equipment which is in direct contact with the patient. In this situation, a distinction is made between on or under the skin, i.e. inside the body. Both classes also impose higher or safer isolating distances (MOPs – Means of Protection). In this case, this is designated as MOPP (Means of Patient Protection) – one of the innovations with IEC/EN60601 3rd Edition.

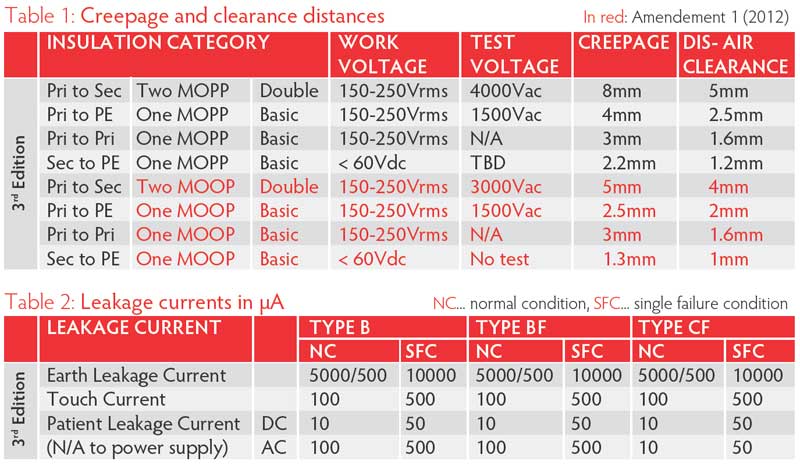

All the classifications referred to up to now relate – without exception – to equipment. The power supply unit or the power supply as a key component can indeed simplify this requirement, but this does not mean that they will fulfil it alone. For example, when combined with a DC/DC converter securing the additional insulating distance, a general B-classified IEC/EN60601 power supply unit can become one for direct patient contact. The same also applies to the maximum leakage currents. The table below provides an overview of the relevant air clearance and creepage distances.

In addition to the air clearance and creepage distances, the IEC/EN60601 standard also imposes restrictions on what are referred to as patient leakage currents, under normal circumstances and in the event of a fault or failure, to much lower values than with ITE-classified devices. As well as the mains-side leakage current, a decisive role is also played in this situation by the “touch current” (formerly the enclosure Leakage current according to IEC/EN60601 2nd Ed.), effectively the same as the patient leakage current (see table 2).

In addition to the air clearance and creepage distances, the IEC/EN60601 standard also imposes restrictions on what are referred to as patient leakage currents, under normal circumstances and in the event of a fault or failure, to much lower values than with ITE-classified devices. As well as the mains-side leakage current, a decisive role is also played in this situation by the “touch current” (formerly the enclosure Leakage current according to IEC/EN60601 2nd Ed.), effectively the same as the patient leakage current (see table 2).

If a power supply fulfils both criteria – on the one hand, the BF classification, and, on the other, the version in protection class II relevant to mobile devices – then it is perfectly suited for the growth market referred to at the beginning, homecare or mobile health. But caution is needed, because in April 2017 a new revision of IEC/EN60601 is coming into force – Edition 4. This tightens things up even more with regard to ESD tests (air discharge 15kV, contact discharge 8kV), as well as interference immunity (IEC61000-4-8 and IEC 61000-4-3) for home healthcare devices, as they are referred to in the Standard. Another exciting point to watch is the further development in miniaturization. Increasing efficiency, driven not least by the ErP L5 (Energy Reduction Program) and DoE VI (Department of Energy), means that standard sizes are constantly becoming smaller. For example, ten years ago, a 200W power supply unit still needed 3×5” of space, and even then 200W could only be achieved with forced cooling. Nowadays, a comparable device only needs 2×3”, and is only 1” high.

This miniaturisation will play a decisive role over the next few years; despite increased efficiencies, the trend is moving away from exclusively forced cooling, towards a combination with contact cooling. This means less noise and less maintenance, ideal for portable medical devices.

For a number of years CODICO has been focusing on medical technology products, and, with RECOM and EOS Power, calls two powerful players in the fields of power supply units and medical DC/DC modules their partners. New from EOS Power is the WLC series, which on just 5×3“ (127×76.2mm) delivers up to 550W. The special feature with this series is the combination of contact cooling, natural convection, and forced cooling. Thanks to an offset contact plate, thermal contacting can be achieved at a cooling element or at the housing of the particular application. The new series is approved in accordance with IEC/EN60601-1-2 4th Edition, and provides classification in accordance with BF, as well as 2×MOPP between input and output. The series operates with a standby current consumption of only 0.5W, and is available a class I and II equipment.

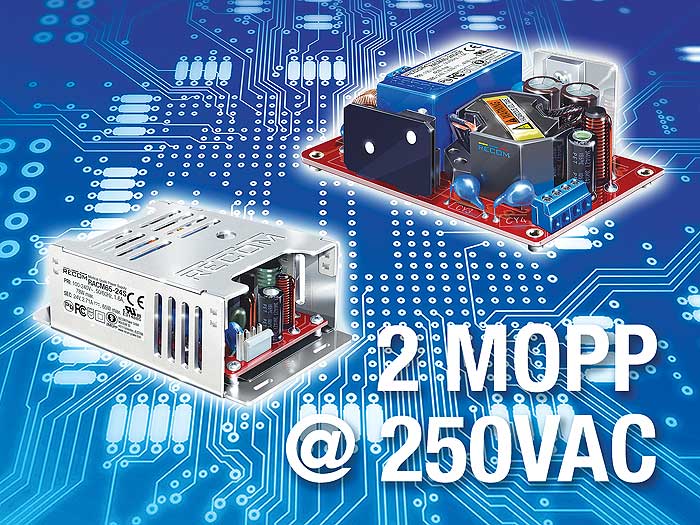

Conversely, RECOM’s RACM Series focuses on full power capacity without derating, no matter if housing is used or not (2×3“, 40W-100W, convection/contact cooled up to 80°C ambient temperature).

RECOM’s medical power supply units from the RACM Series can be operated with full capacity even in hermetically sealed housings. This is particularly advantageous in situations in which a fan cannot be used for reasons of hygiene, noise development, or safety, or in order to avoid contamination. There are three different series available, delivering constant output ratings from 40W to 100W and adjustable output voltages from 5V to 48VDC – and all without the need for a fan. All the power supply units are certified for medical use in accordance with UL, CE and 3rd Edition, with 2×MOPP/250VAC, and comprise a very low leakage current (<75μA) and BF-classification. Output voltages range from 5V to 48VDC.

The RACM Series provides a degree of efficiency of up to 93%, low power loss, and precise regulation over a broad load and input range. The standby consumption is less than 0.3W, which means that the modules also meet the ErP Directive. The 40W and 65W versions are certified both as a 2×3“ open-frame variant as well as with a metal housing, which allows for optimum contact cooling combined with user protection. The PCB in the 100W version in the metal housing likewise measures just 2×3”. The power supply units can be operated at temperatures from -40 to +80°C without derating. The Class II power supply units come with reinforced isolation of 4kVAC between the input and output, and 1.5kVAC between input and output and EMC ground. All the modules meet the Standards EN60601-1-2, FCC18 and EN55022 Class B EMC, and come with a 5-year guarantee.

The RACM Series provides a degree of efficiency of up to 93%, low power loss, and precise regulation over a broad load and input range. The standby consumption is less than 0.3W, which means that the modules also meet the ErP Directive. The 40W and 65W versions are certified both as a 2×3“ open-frame variant as well as with a metal housing, which allows for optimum contact cooling combined with user protection. The PCB in the 100W version in the metal housing likewise measures just 2×3”. The power supply units can be operated at temperatures from -40 to +80°C without derating. The Class II power supply units come with reinforced isolation of 4kVAC between the input and output, and 1.5kVAC between input and output and EMC ground. All the modules meet the Standards EN60601-1-2, FCC18 and EN55022 Class B EMC, and come with a 5-year guarantee.

These robust power supply units also meet the provisions of IEC60068 for shock and vibration. This makes them particularly well-suited for installation in portable medical devices for use in hospitals, medical practices, or homecare nursing. And, thanks to the classification for altitudes of 5000m above sea level, they can also be used in air ambulance flights or medical practices in high locations. The 2×3” family has just recently been complimended by a 150W version on 2×4”. This delivers peak power values of 150W, and is optionally available with an intelligent fan for constant operation at 150W without derating.

Contact:

Ivan Mitic – Tel: +43 1 86305 194

e-mail: ivan.mitic@codico.com

Andreas Hanausek – Tel: +43 1 86305 131

e-mail: andreas.hanausek@codico.com

CODICO | www.codico.com | https://www.codico.com/shop/en/highlights.html