Launched this May, the HARTING Technology Group is now continuing its successful “HARTING Experts Camp” with the autumn kick-off. Under the HARTING Experts Camp label, the connectivity specialist is now offering a powerful platform facilitating customer dialogue and communication. The focus for the autumn is on the very latest developments and solutions in the field of “Connectivity for Future Technologies”.

“The three megatrends of globalization, demographic change and climate change are today’s crucial challenges,” as Dr.-Ing. Kurt D. Bettenhausen, Member of the Board of Management responsible for “New Technologies and Development” at HARTING, emphasizes. Consequently, manufacturing must be converted even more strongly to energy efficiency and sustainability. In the field of automation, Bettenhausen believes that the three trends of digital twin, modularity and connectivity will exert a decisive influence on further developments. “The machines and systems will become more autonomous – and in the future will make more and more independent decisions,” says Bettenhausen.

Interfaces enabling e-mobility

The solutions in the field of Han® connectors are also largely derived from the above-mentioned megatrends of the coming years. The basis for environmentally friendly e-mobility is the seamless, smooth and sustainable use of renewable energies. This can only be achieved by energy storage systems (ESS), as these allow for the time-delayed, demand-oriented utilization of the electricity generated.

The use of connectors accelerates the development of battery module based energy storage systems. These modules are encountered in many different applications, such as e-scooters, driverless transport vehicles (AGVs) and also e-buses.

In addition to the proven solution for “blind plugging” with the Han-Modular® docking frame in the rear area of the energy storage racks, HARTING is now also offering a solution for the front cabling of energy storage systems with the new Han® S. The new connector series offers users optimum safety, as the design meets all technical requirements and the new UL 4128 standard for stationary energy storage systems. As a result, Han® S is meeting the highest standards markets are demanding. Both the proven Han-Modular® solution and the Han® S can be supplied preassembled with the cables, depending on customer specifications.

DC generation saves energy costs

Environmentally friendly e-mobility and renewable energies go hand in hand. Extensive areas of renewable energies and also storage technology are DC dominated. In conjunction with energy recovery measures, the growth in renewables is leading to an overall decrease in energy consumption from the AC grid. Industrial companies harnessing DC generation are saving energy costs and contributing to meeting CO2 emission targets.

Energy storage systems can also reduce peaks in power consumption, which in turn lowers costs. In parts of the world where power failures are more common, a DC infrastructure with energy storage devices also presents options for bridging outages. Consequently, HARTING is participating in the DC-INDUSTRY joint project, comprising some 40 industrial partners. The company focuses on the areas of overall design, energy management and protective measures. Concrete topics are DC connectivity, selectivity, insulation monitoring and ageing behaviour of insulating materials. Central requirements for future interfaces will be derived from the work in the cooperative project.

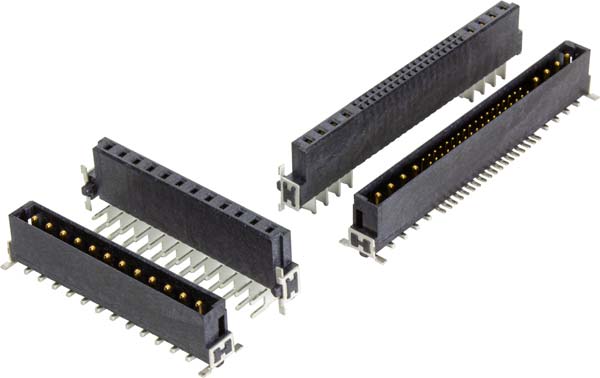

The flexible and self-configurable har-modular® board solution is setting new standards for miniaturized power and data transmission in the device – just like the new har-flex® hybrid solutions.

High-quality product data advancing accelerated development processes

Thanks to expedient, targeted utilization of data and the associated processes is capable of delivering high efficiency gains in the design-in process in industry. In response to this situation, HARTING is linking its products with information packages supporting users. By providing CADENAS Multi CAD, HARTING is covering over 95% of the CAD systems market. This means that 150 native and high-quality data formats are available for HARTING products, whether for individual parts or connector configurations. ECAD data (ZUKEN E3, EPLAN) are also available at the push of a button. In this way, users can dispense with generating component data, thereby saving valuable time.

Thanks to expedient, targeted utilization of data and the associated processes is capable of delivering high efficiency gains in the design-in process in industry. In response to this situation, HARTING is linking its products with information packages supporting users. By providing CADENAS Multi CAD, HARTING is covering over 95% of the CAD systems market. This means that 150 native and high-quality data formats are available for HARTING products, whether for individual parts or connector configurations. ECAD data (ZUKEN E3, EPLAN) are also available at the push of a button. In this way, users can dispense with generating component data, thereby saving valuable time.

Advanced Ethernet modularization and miniaturization as IIoT driver

The transformation of industrial production is also being advanced by IIoT. At the field level of factory automation, analogue systems are rapidly being replaced by digital systems. Data is being generated in ever greater volumes and at increased frequency. But all this data is of little use if there is no suitable infrastructure in place to bring it to its destination. User demands are clear: connectors in devices and infrastructure must continue to contract, while also becoming more powerful at the same time.

This calls for novel approaches: The requirements of future developments within the framework of IIoT must be identified at an early stage and expedient solutions derived. HARTING took this path several years ago for Ethernet connectivity and created new connectors that went on to set the new standards for both PCB and device connectivity.

In the autumn of 2020 HARTING will be meeting these challenges with the strong partnership in the SPE Industrial Partner Network advancing a consistent SPE Ecosystem and entirely new solutions for PCB applications. The flexible and self-configurable

har-modular® board solution is setting new standards for miniaturized power and data transmission in the device – just like the new har-flex® hybrid solutions.

Fielding new products designed for the future, HARTING is solving the challenges of Advanced Ethernet modularization and miniaturization as the key IIoT drivers.