The Moore’s Law scaling phenomenon observes ever-increasing integration in the digital landscape. Constantly shrinking transistor geometries (node sizes) means more functionality can be integrated into the same die area. Die size reductions are accompanied by less power dissipation, making further integration feasible from an energy and thermal perspective. The results are faster and more powerful microprocessors, denser memory devices, and more capable system-on-a-chip (SoC) IC’s that integrate what was, not too long ago, one or more circuit card’s worth of IC’s onto a single IC today. More recently, this integration has included analog functions along-side digital on a common die, from basic comparators to ADCs, DACs, sensors, mixers, analog muxes and more. This perspective explores the benefits of integration to analog.

by Chris Sullivan, Global Head of Solutions Marketing

There are numerous benefits integration provides; the opportunity for footprint (board space) reduction, reduced power dissipation, higher performance, and potential cost savings. These are the type of advantages that, thanks to Moore’s Law, digital designers have enjoyed and exploited.

Analog integration into a typically all digital IC can also help reduce the amount of uncertainty inherent in analog design. Silicon vendors provide well characterised and bounded building blocks that perform within specified parameters. Often the integrated building blocks allow for customisation and on-the-fly modifications – something difficult, if not impossible, to achieve in traditional discrete level analog circuits. The silicon manufacturer solves many of the typical analog design concerns, with worst-case scenarios typically already tested, characterised, and specified. Integration allows designers to work on a more granular level.

The ease-of-use benefits and pre-verified aspects of integration result in less design time, less time selecting individual discrete components and less time calculating and checking component parameters. This all improves time-to-market, which will likely result in monetary benefit.

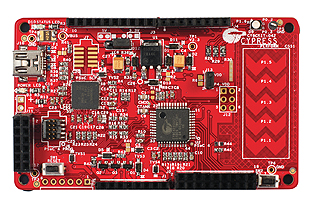

While analog integration has been around for many years in the form of mixed signal ASIC’s and standard cell IC’s, more recently this integration has been adopted and made available in more main-stream ASSP style devices. There are an increasing number of silicon vendors that offer various levels of analog functionality integrated into what were previously all digital IC’s. Nearly all microcontrollers and microprocessors include some level of analog integration. Additionally, there are devices that integrate various forms of programmable analog logic including FPGAs, and PSoCs. Premier Farnell carries a broad range analog enabled products from a number of leading manufacturers.

However, it is important to understand the challenges inherent in combining analog and digital circuits:

For the digital functions, there is a continuing drive to smaller geometries to support higher density and lower power. However, the smaller feature of a digital process may result in worse analog properties.

Let’s think about a chip where a mix of high-speed analog functions and high-density digital circuitry is required.

Technology requirements are different for the two parts of this mix, with the best process for low-power, high-density digital circuits not necessarily suitable for high-speed analog circuits. With process nodes hitting 28nm and below, analog properties are not optimal anymore.

This may slow down future levels of mixed signal integration, or even reverse the trend.

Sometimes, even where it is technically feasible to implement an analog function on a digital optimized IC, it may not be convenient from an economic point of view. Analog functions may perform perfectly well on 130nm processes and above at a considerable lower cost with respect to how they perform if pushed onto 45nm nodes and below simply for the sake of increased integration.

For systems with a generic microcontroller with the analog functions in separate devices, the components are much easier to replace or second source. If the microcontroller does not incorporate the analog functions, it can be substituted by any microcontroller of equivalent capability that is able to communicate with and control the slave analog devices in the system. In the same way, if some or all of the analog devices are separate, they can be replaced with equivalent components if better ICs become available.

Instead, if the microcontroller is special-purpose with integrated analog components, it may not be possible to find another microcontroller from a different manufacturer that does exactly the same thing.

Similarly, spreading the functions out, the designer is in control of exactly what the system is capable of and what it is not. Moving to an integrated “all-in-one” microcontroller means limiting the designer to the combinations of features available for that device. If three ADCs are needed and the microcontroller only allows two, the designer will have to add another external ADC to the design or change to a different microcontroller. And if the microcontroller supports capabilities or interfaces that the design does not actually use, then those capabilities (and the additional cost and complexity in the microcontroller that they represent) are wasted.

Finally, there is the matter of sourcing flexibility: analog design has always been a specialized art. Often also highly dense digital ICs derive from specialized expertise. Companies that invest in specific competencies in one area often find it challenging to do it in the other area too. This is why it is rare to see companies that compete in both areas with the same strength.

In summary, for an increasing range of circuitry and function, analog integration can and should be considered. The benefits are too great to ignore. However, combining analog circuits on a digital IC substrate can be very difficult. There will be performance trade-offs, and sometimes the analog side will not be as good as the application demands. At Premier Farnell it is easy to connect with the world-leaders in signal processing, and designers have at their disposal an incredible, best-in-class range of products and solutions for data conversion, amplifiers and power management.

www.farnell.com