As a global leader in the development and manufacture of commercial fire alarm and detection systems, it is critical that market-leading company Advanced invest in capital equipment to enhance production. To ensure it continuously uses the most-advanced technology and systems, Advanced recently invested in new equipment from Altus Group.

As a global leader in the development and manufacture of commercial fire alarm and detection systems, it is critical that market-leading company Advanced invest in capital equipment to enhance production. To ensure it continuously uses the most-advanced technology and systems, Advanced recently invested in new equipment from Altus Group.

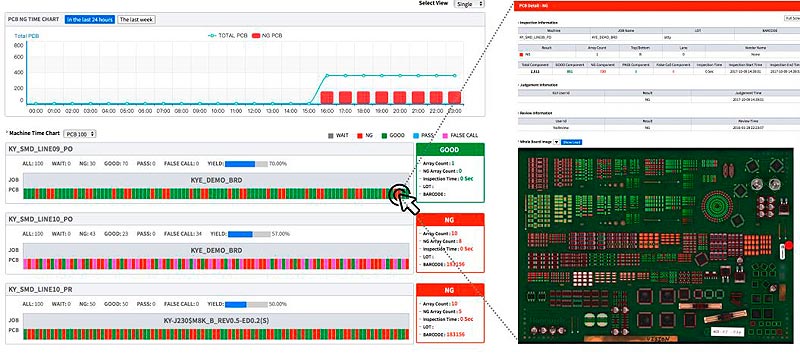

Following the research of Advanced and its production requirements, Altus recommended Koh Young 3D AOI inspection systems which incorporates KSMART a measurement-based process analysis solution which allows manufacturers to implement Industry 4.0 with reliable full 3D measurement data.

The use of 3D AOI systems are an important method of inspection. Measurement accuracy is increasingly fundamental. As the components used in modern electronic assembles become smaller, the need to offer reliable and traceable processes for critical applications like those used within Advanced’s fire systems become even more critical.

“Implementing the most reliable and accurate inspection processes is of the utmost important to us because our products are safety critical and can be lifesaving if called into action,” said Steve Gee, Engineering Manager from Advanced.

“Implementing the most reliable and accurate inspection processes is of the utmost important to us because our products are safety critical and can be lifesaving if called into action,” said Steve Gee, Engineering Manager from Advanced.

“It is vital during production that we have zero escapes. We must also not compromise on false calls for our operators. Through our evaluation, we saw that the Koh Young platform, which uses full 3D light measurement instead of optical 2D AOIs, would create that peace of mind of no escapes whilst also delivering very low false calls.

“It is vital during production that we have zero escapes. We must also not compromise on false calls for our operators. Through our evaluation, we saw that the Koh Young platform, which uses full 3D light measurement instead of optical 2D AOIs, would create that peace of mind of no escapes whilst also delivering very low false calls.

‘’Aside from the support and known reputation of Koh Young and Altus, what was also significant in our decision making was how the Koh Young platform unlocks the data the AOI collects.”

Koh Young’s 3D AOI solutions intelligently combine technologies with superior hardware to ensure inspection tolerances are precise, providing meaningful insights about the process and eliminating the root causes of a defect through measurement data generated from 3D AOIs.

Tony Sweetman, Altus Sales Manager concluded: “The Advanced team were ideal to work with and are a customer that quickly understood the differences between full 3D measurement and the other offerings on the market using legacy technology.

“Certainly, we had to prove out our capabilities and show them how the system could add value, but it was great to support a new knowledgeable company. We are looking forward to working on more projects with Advanced in the future and building on this new relationship.’’