Portable battery-powered devices such as earbuds, smartwatches, and gaming controllers are expected to deliver long-lasting performance for a better user experience. The challenge for designers lies in extending battery life when battery capacity is limited by the small form factor of these electronic products. The right power management architecture can make all the difference in delighting or disappointing end users.

This article takes a look at how a single-inductor multiple-output (SIMO) power converter architecture balances battery life versus space constraint demands of products like hearables and wearables.

Figure 1: Portable electronics such as fitness trackers must offer long battery life for a pleasing user experience.

Smaller Footprint, Higher Efficiency

Let’s consider a typical power management system for a hearable device. Such systems usually have a power management IC (PMIC) that offers a battery charger, a buck converter, and low-dropout regulators (LDOs). For example, a dual LDO may power the Bluetooth and audio. In a typical implementation, overall efficiency is under 70% because the LDOs are used for multiple rails. To improve efficiency, one option is to use switching regulators instead of LDOs. However, each switching regulator would require a separate inductor for each output in order to service each voltage rail. Considering how large and expensive inductors are, this implementation isn’t practical for very small electronics.

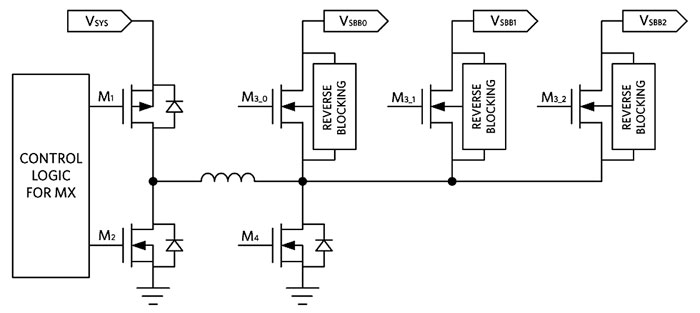

Conversely, a SIMO architecture provides much greater efficiency, particularly for products powered by small lithium-ion batteries. Consider a SIMO buck-boost regulator provided by Maxim as an example (MAX77650). Maxim’s SIMO buck-boost regulators have a single inductor that regulates up to three output voltages over wide output voltage ranges. This approach results in a smaller total footprint compared to the traditional architecture by eliminating multiple discrete components. It also delivers high efficiency.

Figure 2 depicts a diagram of the SIMO buck-boost regulator.

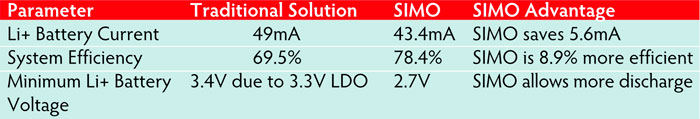

In Table 1, you can see a comparison of the SIMO architecture versus a traditional power management solution. The SIMO is able to deliver high efficiency on each output with this architecture. The converter maintains the low loss of a traditional inductive switching converter by still turning on switches with near-zero volts across the devices, which keeps the dissipation low. The SIMO device also time-shares the inductor to each output using low-loss switches, a technique that allows it to keep the same high-efficiency benefits that would be expected from a buck-boost converter.

Inductor saturation current (ISAT), which provides an electrical current measure when the inductance drops to 70% of its value, is based on the inductor’s core size for a given core material and construction. Compared to using separate DC-DC converters, the SIMO architecture with a single inductor provides many advantages:

• Reduced cost and footprint

• Quantization of available component values

• Time multiplexing when different features in the end device aren’t used at the same time, allowing them to share their required ISAT − a useful benefit for events that occur sequentially using different rail voltages

• Averaging − even when channels aren’t time-multiplexed, peak power consumption of different features does not occur simultaneously, which can lower the total inductor ISAT requirement

Tackling SIMO Architecture Tradeoffs

A well-thought-out design illustrates the tradeoff benefits inherent in the SIMO architecture. Ripple voltage tends to be higher with SIMO devices, for example, because a single inductor is providing buckets of energy to alternate outputs. Also, the output voltage ripple may increase because when the SIMO is heavily loaded, it becomes time-limited and there can be a delay in servicing each channel. You can offset the sources of output voltage ripple by implementing larger output caps, which would allow you to maintain a net footprint/BOM advantage. A SIMO architecture may also exhibit more crosstalk than its traditional counterpart.

Maxim has several SIMO PMICs that can help you manage these tradeoffs. Two of them are the MAX77650 and MAX77651, which integrate a battery charger and regulation for powering the sensor, the microcontroller, Bluetooth, and audio. Overall system efficiency is 8.9% higher compared to the alternative solution presented in Table 1. The devices feature micropower SIMO buck-boost DC-DC converters as well as a 150mA LDO, which provides ripple rejection for noise-sensitive applications like audio. To minimize crosstalk and undershoot on bus signals, while also protecting device inputs from high-voltage spikes on the bus lines, there are optional resistors in series with the serial data line (SDA) and serial clock line (SCL). To further minimize crosstalk and also prevent oscillation, the devices always operate in discontinuous conduction (DCM) mode, so the inductor current goes to zero at the end of each cycle. The PMICs also help extend battery life for the end applications as each of their blocks has low quiescent current (1µA per output). Since the devices offer high-frequency operation, they can use a small inductor. The devices are available in a 2.75mm × 2.15mm × 0.7mm WLP package.

Compared to a buck-only SIMO, a buck-boost topology makes good use of the inductor because it needs less time to service each channel. With a buck-only SIMO, operation suffers when an output voltage approaches the battery voltage, as the device would require the inductor for too much time, thus affecting other channels. Generally, solutions that need at least one boost voltage are better served with a buck-boost SIMO.

Hearable Use Case: No Sacrifices with SIMO

Designing hearables, in particular, involves addressing some unpleasant tradeoffs. Many hearable devices integrate one or more optical or inertial MEMS sensors and also utilize LEDs. Using photoplethysmography (PPG), an integrated optical sensor can measure health parameters such as pulse rate and blood-oxygen saturation. In order to generate the light intensity needed in these types of devices, the LEDs must run at a higher voltage range (4V to 5V) than lithium-ion batteries typically provide. As a result, designers are left with a few choices. They can add a buck-boost to their system, which means another device. They can add another inductor and additional capacitors, which also takes up valuable real estate. Finally, they can opt to live with the higher power dissipation, not an ideal scenario when it comes to small electronics since the battery size is important. SIMO buck-boost technology, however, allows designers to use one of the outputs, set to the desired voltage (up to 5.2V) to drive the LED and also enhance sensor performance.

Summary

When an electronic device is as small as an earbud or a medical patch, you can imagine how limited the battery capacity is. Yet, long-lasting performance is important for the user experience. Traditional power management architectures, with their use of large inductors, aren’t suitable for these types of devices. A SIMO architecture, on the other hand, offers advantages in efficiency and extended battery life in a much smaller footprint.

Authors: Cary Delano, Distinguished Member of Technical Staff, and Gaurav Mital, Principal Member of Technical Staff, Mobile Power Solutions, Maxim Integrated

![]() Maxim Integrated

Maxim Integrated

www.maximintegrated.com