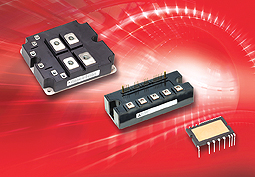

Mitsubishi Electric Corporation has launched three different hybrid Silicon Carbide (SiC) power modules for use in home appliances, industrial equipment and railway traction applications. Depending on the target application Mitsubishi offers these three different versions in three different packages. Every new hybrid SiC power module is equipped with Si-IGBTs and SiC Schottky-barrier diodes (SBD) in order to reduce the size, decrease the weight and increase the efficiency of inverters. Model PSH20L91B6-A, which is a Hybrid SiC DIPPFC™ (Transfer-molded-type IPM with integrated PFC), is designed for use in home appliances. PMH200CS1D060 – a Hybrid SiC-IPM – is intended for industrial applications, and the Hybrid SiC Module CMH1200DC-34S is designed specifically to fulfil the needs of railway traction applications. In the Hybrid SiC DIPPFC™ for home appliances the SiC SBDs eliminate the recovery current of the free-wheel diodes and decrease EMI noise. The device is rated for 600V/20Arms. Switching frequencies up to 30kHz enable designers to use smaller inductive components resulting in smaller form factors of the overall system. The integrated PFC circuit as well as the driver part further reduce the footprint and simplify the wiring patterns. In terms of package dimensions (24 mm x 38 mm) the PSH20L91B6-A devices are compatible with Mitsubishi Electric’s Super Mini DIPIPMTM products. The Hybrid SiC modules for railway traction systems reduce power losses by about 30% compared to Mitsubishi Electric’s CM1200DC-34N (N-series IGBT) thus enabling more efficient devices. The device is rated for 1700V/1200A. Package (140 mm × 130 mm) and terminals are compatible with Mitsubishi Electric’s CM1200DC-34N (N-series IGBT).

MITSUBISHI ELECTRIC EUROPE

www.mitsubishichips.eu