The camera, radar and LiDAR systems installed in passenger cars and trucks have to accurately function in all weather conditions.

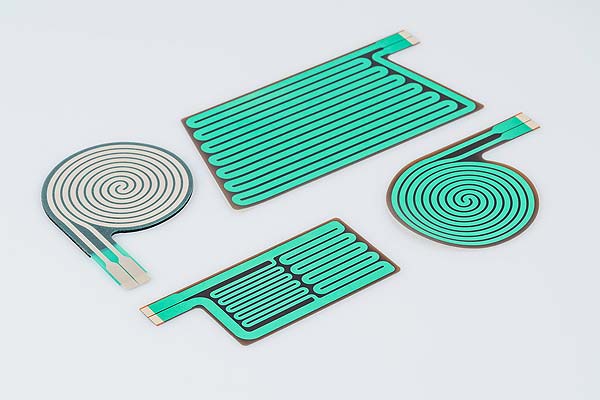

The functional films are lightweight, flat and flexible so that they can be applied close or directly to the sensor with minimal space requirements, which makes them ideally suited for this specific type of application. The flexibility of the films and the variable design of the conductive tracks allow for customization of the film heater in terms of shape and size, and adaption to any geometry and curvature of the component. Due to state-of-the-art die cutting, laser and printing technologies, even complex contours with tight tolerances can be achieved. The planar surface of the printed heating structures avoids the conductive tracks potentially being visible in installed condition. The heating solution is also available as a self-adhesive version, which reduces installation requirements.

A special forte of this solution: Individual heating performance can be adapted to the parameters of temperature, voltage, surface heating performance and homogeneity. This flexibility makes it possible to find the ideal solution for the respective ambient conditions and customer requirements. The film heater can be installed very close to the sensor, which results in fast heating and thus ensures reliable sensor performance.

Another advantage: The film heater can be integrated into existing customer processes such as adhesive bonding, insert molding and clamping.