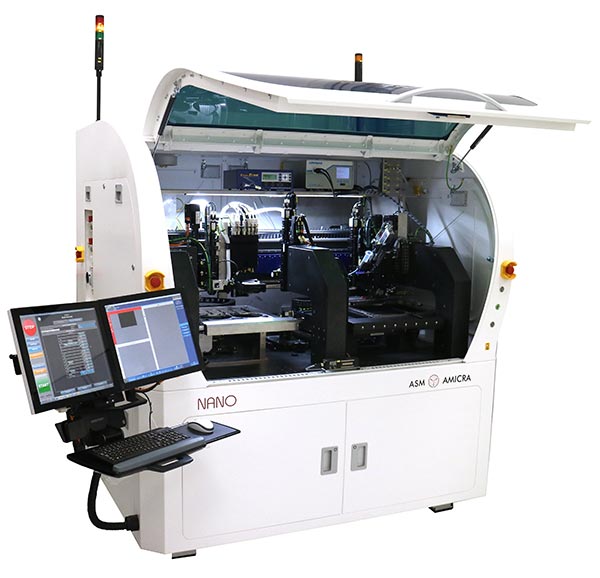

AMICRA NANO is an ultra-precision die and flip-chip bonder (±0.3µm@3s ) for highly demanding assembly tasks and is the highest-precision placement system in its class. Aiming at today’s and future placement demands, NANO enables the reliable handling of ultra-small and very thin dies. — Image source: ASM

Integrated, powerful and highly miniaturized communication modules are the main components in new generations of devices for 5G, the Internet of Things (IoT) and autonomous driving. As a technology leader and the world’s largest equipment supplier to the electronics industry, ASM offers strong solutions for entire process chains ranging from fan-out to die-bonding and active alignment to molding, testing and packaging. At the Productronica 2021, ASM presents in its Advanced Packaging Area solutions for the latest SiP generation with the SIPLACE TX micron and the AMICRA NANO, along with many other innovations.

AMICRA NANO – The precision leader

With an accuracy of 0.3 microns @ 3 sigma, the AMICRA NANO is considered to be the most precise die-bonder in its class. Due to its outstanding placement accuracy and support for a eutectic high-speed bonding process, the die and flip-chip bonder is particularly well suited for the reliable handling of ultra-small and very thin chips. As the industry’s technology leader, ASM AMICRA has developed high-resolution imaging systems to support the dynamic alignment system, implemented a fiber laser as the primary heat source for eutectic die bonding, and installed high-resolution motion control systems on a granite base with a special vibration damping system.

In a footprint of only 2.23 by 1.0 meters (7.3 by 3.3 feet), the new SIPLACE TX micron can place up to 96,000 cph with accuracy levels of up to 15 microns @ 3σ and placement distances of as little as 50 microns. — Image source: ASM

At the heart of the AMICRA NANO image processing-controlled die-bonder, four imaging systems are mounted in fixed positions on a granite base while all other motion control systems move around the imaging cameras. This design concept has been an essential factor in the development of high-precision placement systems to this day.

SIPLACE TX micron – High speed for high density

With up to 96,000 components per hour, placement accuracies of 25, 20 or 15 microns @ 3 sigma and minimum placement distances of as little as 50 microns, the SIPLACE TX micron stands for advanced packaging and high-density applications with unsurpassed productivity. The highest accuracy class is achieved with a new vacuum tool that features an exchangeable magnetic plate for rapid product changeovers. The new 4-mm versions of the Smart Feeder Xi also play a role in the fast and exceptionally precise pickups of even the smallest components and dies. They use the latest micro-tapes and vacuum-level the bottoms of the blister pockets to prevent inclined positions of components within the tape.

Thin-die handling in gentle mode

In the 4-mm module of the SIPLACE SmartFeeder Xi, the bottoms of the blister pockets can be vacuum-leveled to ensure that even the smallest components are positioned correctly. — Image source: ASM

Since thin dies, flip-chips and the smallest 0201m components require extremely gentle handling, the whole placement process of the SIPLACE TX micron can be individually programmed for each component and placement position with features like touchless pickup and zero-force placement. And for sensitive thin dies, the vision system features advanced image processing algorithms such as cracked-die inspection and die-chipping detection. This way, components with hairline fractures and lacerated edges are detected and rejected already during the pickup process.

A real space saver

The new SIPLACE TX micron delivers all this performance in the smallest possible space. Like its predecessor model, it occupies a footprint of only 2.23 by 1.0 meters (approx. 7.3 by 3.3 feet), which makes it a particularly attractive option for tight cleanroom environments thanks to its DIN EN ISO 14644-1 Class 7 certification.

Ready for the integrated smart factory

The optional vacuum tooling makes it possible to operate with the highest placement precision of 15 microns @ 3σ. — Image source: ASM

Like all current ASM solutions, the SIPLACE TX micron features a broad range of M2M and networking capabilities. Open and standardized interfaces such as ASM OIB, IPC-HERMES-9852, IPC-CFX and IPC-SMEMA-9851 allow it to be fully integrated into workflows, higher-level MES/ERP systems, traceability solutions, and the integrated smart factory.