Panasonic fiber lasers fulfill the requirements for the new generation of laser welding systems, revolutionizing the welding of plastic components.

Panasonic fiber lasers fulfill the requirements for the new generation of laser welding systems, revolutionizing the welding of plastic components.

The requirements in the plastic industry are high: While manufacturing and production process is accelerating, products are becoming ever more complex. All products should be marked for identification to ensure product quality and to allow for tracing in case of consequential damage.

Panasonic Industry laser marking systems are already firmly established in the market due to their outstanding quality and exclusive services. The unique MOFPA (Master Oscillator Fiber Power Amplifier) fiber laser technology, which has a proven track record for identification marking of plastic components sets the Panasonic Industry laser marking systems apart. This expertise and many years of experience have been incorporated into the development of the new VL-W1 laser welding system.

Fiber laser technology offers what is currently the most energy-efficient and cost-effective system for laser processing of plastic parts, as this laser can operate with practically no maintenance.

Competence in laser welding of plastics

Laser welding of plastics offers decisive advantages compared to conventional bonding technology (ultrasonic welding, gluing, etc.). Laser welding is a clean and precise process in which the plastic components can be joined without visible welding seams. Joining by means of laser energy does not leave any adhesive residue and also produces no wear particles, which can lead to problems on the finished component later on. The process energy required for bonding can also be introduced selectively and with only slight pressure on the bonding surface for laser-welded components in comparison to other methods. That not only ensures stress-free joining of components with very little warping, but is also extremely energy-efficient. Laser welding can be adapted very flexibly to the components being welded thanks to the laser systems of the VL-W1 series.

The individual process steps can be monitored and documented completely and are therefore useful for quality control.

The individual process steps can be monitored and documented completely and are therefore useful for quality control.

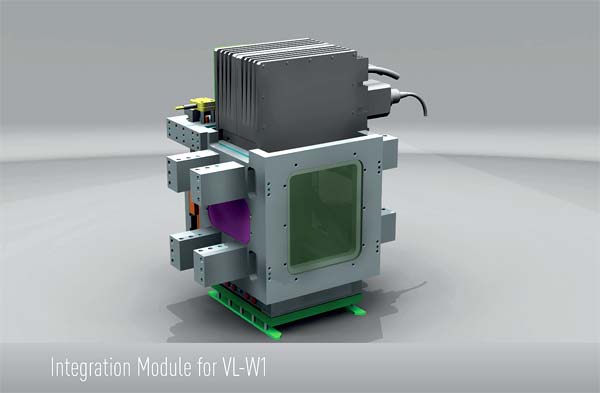

A new integration module was designed especially for Panasonic Industry‘s laser welding system VL-W1. It corresponds exactly to the dimensions and features of the laser welding system. This makes it easier for integrators and machine builders to implement the laser welding process for plastics into their production lines. The construction work and the risks that occur when a new process has to be integrated into an existing line are minimized by the I-Module. A large field of operation (200mm × 150mm) makes it easy to insert various components. Different clamping mechanisms allow tension forces from 400N up to 3000N. A position measuring system with a resolution of 0.003mm assures a very precise placing within the VL-W1.

Panasonic Industry Europe also offers the perfect surrounding for the VL-W1 series: the LCP-3000 workstation. This workstation is suitable for a wide variety of laser welding applications due to possible servo-driven X-,Y- and Z-axis tables or servo-driven rotary indexing table. Even a 360°-solution with rotary shaft is available. The LCP-3000 workstation is equipped with a servo-driven cabin safety door and an internal extraction unit with an optional filter insert. Panasonic Industry Europe offers customized clamping units for every application to provide the perfect solution for individual demands.

For further information about the new laser welding products and solutions of Panasonic Industry Europe please visit www.laser.panasonic.eu

Panasonic Corporation

Panasonic Industry Europe