Indium Corporation will feature its WS-446HF Flux for both flip-chip and ball-attach processes at SEMICON Taiwan 2019, September 18-20, in Taipei, Taiwan.

Indium Corporation will feature its WS-446HF Flux for both flip-chip and ball-attach processes at SEMICON Taiwan 2019, September 18-20, in Taipei, Taiwan.

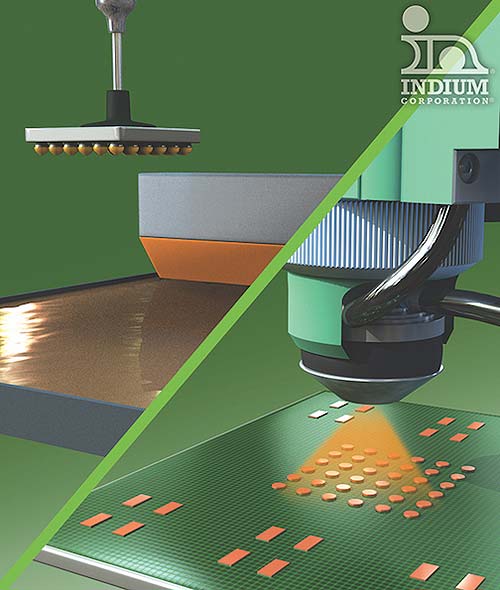

WS-446HF flux is a robust, NIA (no intentionally added), halogen-free, water-wash flux that is designed to provide one simple solution to complicated applications, especially those with a single cleaning step for both BGA ball-attach and flip-chip processes. It has a powerful activator system to promote good wetting on even the most demanding substrate metalizations, such as Cu OSP, ENEPIG, and ENIG. WS-446HF helps to improve production yield by minimizing non-wet open defects, missing balls, and eliminating Electro-Chemical Migration (ECM).

WS-446HF:

- Promotes excellent solderability and wetting on a wide range of surfaces

- Cleans well with room temperature DI water

- Eliminates ECM or dendrite formation caused by residue

Indium Corporation has an industry-proven portfolio of products that meet the current and evolving challenges encountered in fine-pitch SiP and Heterogeneous Integration applications. For more information on Indium Corporation’s materials for SiP, visit www.indium.com/SiP or visit Indium Corporation’s booth #J2440.

Indium Corporation is a premier materials manufacturer and supplier to the global electronics, semiconductor, thin-film, and thermal management markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, the company has global technical support and factories located in China, India, Malaysia, Singapore, South Korea, the United Kingdom, and the USA.