The driving forces behind such machine concepts are the automotive supply industry and the manufacturers of consumer electronics. “The aim here is to integrate all process steps in a machine platform that then needs only a single operator to operate it”, explains Matthias Fehrenbach, managing director of EUTECT GmbH.

The driving forces behind such machine concepts are the automotive supply industry and the manufacturers of consumer electronics. “The aim here is to integrate all process steps in a machine platform that then needs only a single operator to operate it”, explains Matthias Fehrenbach, managing director of EUTECT GmbH.

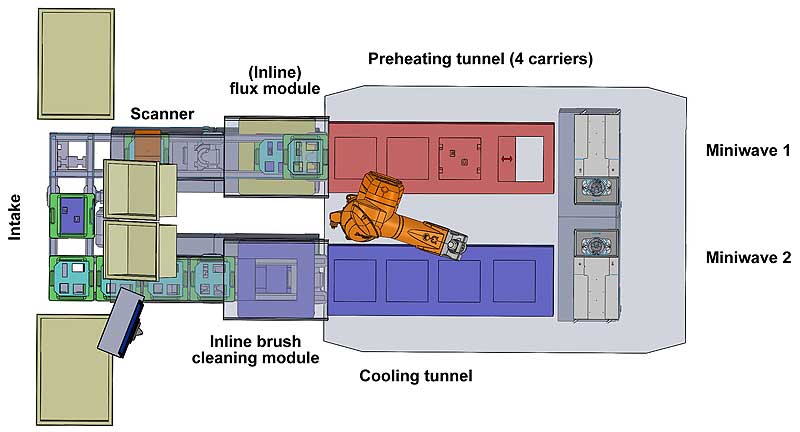

EUTECT meanwhile offers machine cells with dimensions of up to 2 700 mm × 1 600 mm. These cell dimensions are necessary in part because customers integrate up to seven work steps plus the associated kinematic solutions into the machine. “We’ve worked on a broad range of products to date. Here for instance we’ve integrated an input portal, a six-axis overhead robot, an input scanner, a flux module, a pre-heating tunnel, two mini-waves, a cooling tunnel, and a brush station into a single cell. Added to this was the workpiece carrier with the integrated titanium masks”, says Fehrenbach in retrospect. All of the modules are part of EUTECT’s module kit, whereby project management, development, and integration as well as start-up, employee training, and maintenance can be considerably simplified.

“Many of the customers who inquire about such machine concepts today are steady customers“, according to Fehrenbach. Often these customers have small EUTECT systems for individual processes or smaller process combinations in operation. “The customer is familiar our products and employees from this co-operation and he knows what technical know-how and experience we can bring to such a project. On top of this, the customers have become familiar with our individual modules’ performance spectrum“, Fehrenbach reports further.

The complete solutions are populated via an input area. The workpiece supports provided there can be populated both manually and automatically. Error minimization stands in the foreground here. Only one employee is occupied on the system during manual input. His task consists of populating the workpiece carriers and removing the finished components. The workpiece carriers are tailored to the individual components and groups. In part, these are provided with barcodes whereby a downstream scanner can conduct an additional inspection. This is particularly important precisely with regard to traceability. Six-axis robots are generally deployed within the machine. These can be both integrated into the machine level as well as mounted overhead on the machine’s cover for space reasons. The structure and layout of the machines are are worked out in advance evaluations with the customer based on his guidelines and technical specifications.

“Our customers can thus process combined soldering processes on the most complex assemblies quickly and efficiently with a single employee. Especially with large quantities, it’s important to produce easily reproducible soldering points fully automatically, controlled, and monitored. That’s why it doesn’t surprise us that especially the automotive supply industry and the manufacturers of consumer electronics increasingly demand our complete solutions”, summarizes Fehrenbach.

EUTECT® GmbH

www.eutect.de