The compact and automatic table top SV260 Vapor Phase reflow oven is specially designed for R&D and prototype production.

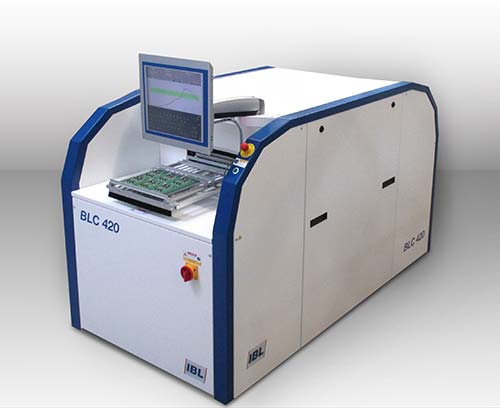

At this year’s IPC APEX EXPO 2025 in Anaheim the German soldering specialist is presenting the SV260 and BLC420 batch systems. The SV260 is an entry-level model for small series, while the BLC420 is designed for the flexible soldering of medium-sized assemblies in stand-alone series production.

“Our vapor phase soldering processes offer precise temperature control, as the maximum temperature is limited by the boiling point of the liquid Galden. This prevents the assembly from overheating, which in turn leads to high, reliable soldering quality, which is particularly important for assemblies that will later be used in sensitive areas such as security technology,” says Sabine Ollila, CEO of IBL Technologies LLC, the sister company of IBL-Löttechnik GmbH. Furthermore, IBL’s vapor phase soldering systems ensure reproducible results and reduced energy consumption. In addition, the process is particularly flexible, as it is suitable for all SMT components and carrier materials. “Our soldering systems, including high-speed in-line ovens, especially those with vacuum chambers, ensure void-free solder connections, which further increases the quality of the solder joint,” OIlila continues.

One of the two exhibition systems is the SV260 (https://ibl-tech.com/en/batch-soldering/). This is a compact and automated table-top vapor phase soldering system that was specially designed for use in development and prototype production. Thanks to its two-chamber design, cooling and process chamber, heat is transferred through condensed vapor, which enables even and gentle heating of the assemblies. In addition, the system works oxygen-free, which prevents oxidation and thus quality losses.

The SV260 is characterized by its user-friendly operation. A 5-inch HMI touch panel allows easy control, while saved standard soldering profiles ensure quick start without complicated parameter settings. Thanks to the USB port, soldering profiles and machine data can be saved and managed directly. The system has real-time temperature monitoring for process control. “The vapor phase system offers various optional extensions to meet individual requirements such as an adapter for double sided assemblies.

The second trade fair exhibit, the BLC420 (https://ibl-tech.com/en/inline-vapor-phase-reflow/), is an environmentally friendly and flexible vapor phase soldering system that was specially developed for demanding soldering processes. “Thanks to the Intelligent Profiling System (IPS), temperature profiles can be precisely controlled to ensure even heat distribution. The patented Soft Vapor Phase technology ensures particularly gentle heating, so that both large and small components can be processed without risk” says Olaf Cieply, Global Sales Manager of IBL-Löttechnik.

The BLC series of Vapor Phase reflow ovens is suitable for complex solder applications and is also available as an in-line version which can be used in batch mode.

A key feature of the BLC series is its low energy consumption, which leads to reduced operating costs. Unlike many other soldering systems, the system operates in an oxygen-free atmosphere without the need for expensive nitrogen. In addition, the two-chamber system with media recovery ensures minimal fluid consumption. The automatic loading and unloading of the workpiece carrier enable smooth operation.

The system is also extremely user-friendly. A 15-inch touchscreen and an integrated PC with professional data management ensure easy operation and permanent data recording. Thanks to network capability and password-protected operating levels, the system is also suitable for use in modern manufacturing processes. Simultaneous soldering of multiple assemblies can be realized depending if they fit onto the workpiece carrier, which can handle weights of up to 7kg.

For additional flexibility, the BLC series offers various expansion options. “Long lifetime and practically any profile can be realized with these machines”, confirmed by Marcio Henandes, Field Service & Application Engineer of IBL Technologies.

The vapor phase soldering systems will be presented to the trade audience by IBL at APEX at booth 2623 from March 18 to 20 at the Anaheim Convention Center.