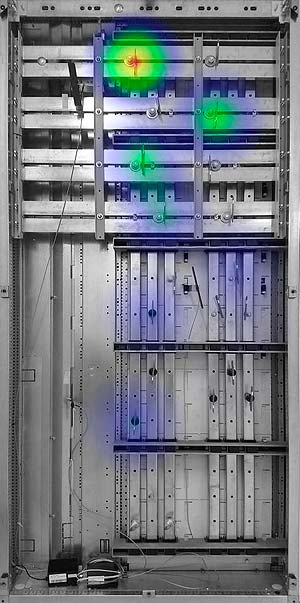

Switchgear is the heart of every industrial plant: it supplies the entire plant with electricity. Continuous monitoring of the temperature in the plants is therefore important. Undiscovered overloads and faulty installations can lead to overheating and even fires. This can lead to equipment failure and shut down production. Such events are often announced in advance by heating up the screw connections on the busbars.

Switchgear is the heart of every industrial plant: it supplies the entire plant with electricity. Continuous monitoring of the temperature in the plants is therefore important. Undiscovered overloads and faulty installations can lead to overheating and even fires. This can lead to equipment failure and shut down production. Such events are often announced in advance by heating up the screw connections on the busbars.

Until now, however, permanent temperature monitoring in switchgear has been difficult: “Up to now, cables or batteries could not be integrated directly on the busbars due to the high voltage. Therefore, the temperature is usually measured with infrared cameras. To do this, the system must be switched off frequently, so continuous measurement is not possible. Wireless systems with RFID sensors are better suited for this,” explains Dr. Andreas Weder, head of development at Fraunhofer IPMS. “Here, the wireless data and power transmission technology familiar from RFID technology is used from reader to sensor. The reader feeds the sensor with energy to carry out the measurement and then transmit the measured values.” Due to the high voltage, it is not possible to apply the sensors directly to the busbars in switchgear. The Fraunhofer IPMS therefore uses a new method “We measure the temperature directly at the screw connection of the busbars,” explains Weder. “In this way, the temperature can be measured continuously and without interference.

Intelligent software solutions also make integration into existing production environments and connection to existing control systems easy. Andreas Weder explains: “Successful system integration of wireless RFID sensor systems often requires extensive know-how ranging from ASIC and antenna design to sensor tag development and sensor, system and cloud integration. Middleware, the so-called RFID-OPC-UA-AutoID-Server (ROAD-Server), implements the OPC-UA AutoID-Companion specification accordingly for RFID sensor components and thus enables manufacturer-independent, standard-compliant communication for industrial automation. This allows any reader, identification and sensor transponder in the different frequency ranges (LF, HF, UHF and NFC) and from different manufacturers to be addressed uniformly.”

Anyone interested in the RFID sensor modules from the Fraunhofer IPMS can get a picture at the RFID Technology Conference and Exhibition RFID & Wireless IoT tomorrow from 29-30 October 2019 in Darmstadt. The Fraunhofer IPMS developers will present sample systems equipped with various sensors and advise on the implementation of RFID sensor systems. The exhibition of the Fraunhofer IPMS can be found at booth 39. Monika Beck from Fraunhofer IPMS will give a lecture on the topic on October 30, 2019 at 3:50 pm.

Fraunhofer Institute for Photonic Microsystems