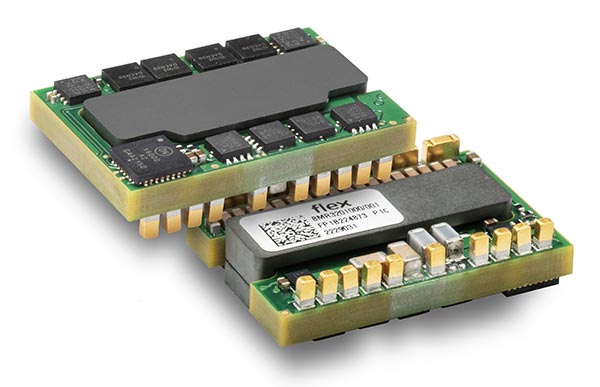

The product operates over a 40-60 VDC input range, producing a 5 to 7.5 VDC output, ideal for powering point of load converters at lower intermediate bus voltages to optimize system efficiency. The BMR320 is rated at 400 W/60 A at 54 V input and achieves an outstanding power density of 128 W/cm3 (2126 W/in3), measuring just 27 x 18 x 6.4 mm. With efficiency peaking at 97.7%, up to three units can be paralleled for a total load of 1080 W. The parts are designed for top-side cooling to a heatsink with airflow or for liquid cooling via a thermal block, and the relatively flat design of the topside of the converter allows for easy connection via a thermal interface material such as a gap pad.

The product operates over a 40-60 VDC input range, producing a 5 to 7.5 VDC output, ideal for powering point of load converters at lower intermediate bus voltages to optimize system efficiency. The BMR320 is rated at 400 W/60 A at 54 V input and achieves an outstanding power density of 128 W/cm3 (2126 W/in3), measuring just 27 x 18 x 6.4 mm. With efficiency peaking at 97.7%, up to three units can be paralleled for a total load of 1080 W. The parts are designed for top-side cooling to a heatsink with airflow or for liquid cooling via a thermal block, and the relatively flat design of the topside of the converter allows for easy connection via a thermal interface material such as a gap pad.

The unregulated, non-isolated architecture used in the BMR320 reduces the output impedance of the converter when compared to regulated designs, which effectively reflects the input bus capacitance efficiently to the output, enhancing its ability to cope with large load transients with minimal “droop”.

The BMR320 protection features include output current limit and over-voltage, along with over-temperature and input undervoltage. A PMBusTM interface is included for monitoring and control and the part is supported by the Flex Power Designer Tool.

Anders Sellin, Strategic Product Manager at Flex Power Modules comments “The BMR320 intermediate bus converter is designed for optimum system efficiency when used alongside point of load converters and Integrated Power Stages such as our BMR510 and up-coming BMR515. It is a great solution for datacom, cloud computing and AI applications, where power density, efficiency and low cost are critical factors”.

The product will be available in OEM quantities by end of this year.