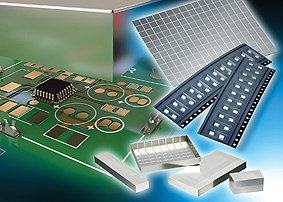

Harwin, the leading hi-rel connector and SMT board hardware manufacturer, now offers its EZ-Shield Can EMC protection screening products in kit form, enabling designers to rapidly construct PCB cans at minimal cost for development purposes.

Harwin’s EZ-Shield Cans are simply pressed onto pre-positioned surface mount EZ-Shield Clips forming an EMC cage around sensitive ICs and electronic circuitry. This saves expensive, labour-intensive secondary assembly and facilitates rework. A range of can sizes and clips are available. However, during development and test, typically engineers have had to order bespoke cans without being 100% certain of their eventual requirements, incurring costs and creating delays.

Now, a can may be created easily and effectively in minutes, with no special tools or experience required.

The low cost kit comprises two 80mm × 60mm × 0.3mm thick Nickel Silver sheets that are pre-scribed on a 5mm grid to allowing easy cutting and forming, enabling the user to produce a shield can of the required dimensions. Auto-placeable EZ-Shield Can Clips which hold the cans securely in place are also included.

Comments Product Manager, Paul Gillam: “Product testing has confirmed that the nickel silver material used provides effective and useable shielding, with up to 24dB attenuation achieved, depending on frequency and configuration. We believe that the kits will save costs and time during development, and help to enable that an optimised EMC solution is found.”

The EZ-Shield Kits complement Harwin’s of standard clips and cans which offer a highly cost effective method of screening. Auto placement of the related clips allows post assembly soldering and de-soldering operations to be eliminated leading to significant reduction in PCB damage. Applications will be found in many markets, ranging from Consumer Electronics through to the Industrial, Instrumentation and Control Systems environment.

Harwin

www.harwin.co.uk