The last few months have been a time for which no one was fully prepared. The epidemic and the resulting economic crisis show how dependent industry is still on its workers. In this article we will look at automation as a method of reducing the risk involved with human labour.

The consequence that comes to mind first as a result of the current world situation is human susceptibility to diseases and their further spread. As can be seen in a number of manufacturing companies currently dealing with the epidemic, one infected worker can have a domino effect by infecting more and imposing quarantine on whole companies at times.

The consequence that comes to mind first as a result of the current world situation is human susceptibility to diseases and their further spread. As can be seen in a number of manufacturing companies currently dealing with the epidemic, one infected worker can have a domino effect by infecting more and imposing quarantine on whole companies at times.

Being a living organism, man is also susceptible to fatigue. A factor that can be understood narrowly – as simple fatigue resulting from working hours, but also broadly – including, for example, fatigue and loss of precision of hands as a consequence of monotony, natural day cycle and random events – such as simple sleeplessness of an employee. The consequence of this factor is also a reduction in the time for which a person can work efficiently on a daily, weekly and monthly basis. In addition, over long periods of time, account should be taken of the ageing of people and the resulting changes in the functioning of their organisms and the ability to regenerate.

The element connecting all the issues discussed above, and thus a consequence of the human factor in its broadest sense, is unpredictability. Man’s work is intrinsically linked to his nature – and this is a factor that cannot be completely eliminated, yet the risks associated with it can be minimized.

The element connecting all the issues discussed above, and thus a consequence of the human factor in its broadest sense, is unpredictability. Man’s work is intrinsically linked to his nature – and this is a factor that cannot be completely eliminated, yet the risks associated with it can be minimized.

The most important method of achieving this goal is automation, defined as replacing and supporting human work by machine work. It is primarily used at those stages of production where the human factor has the greatest significance and potentially negative impact on the results achieved.

The most important method of achieving this goal is automation, defined as replacing and supporting human work by machine work. It is primarily used at those stages of production where the human factor has the greatest significance and potentially negative impact on the results achieved.

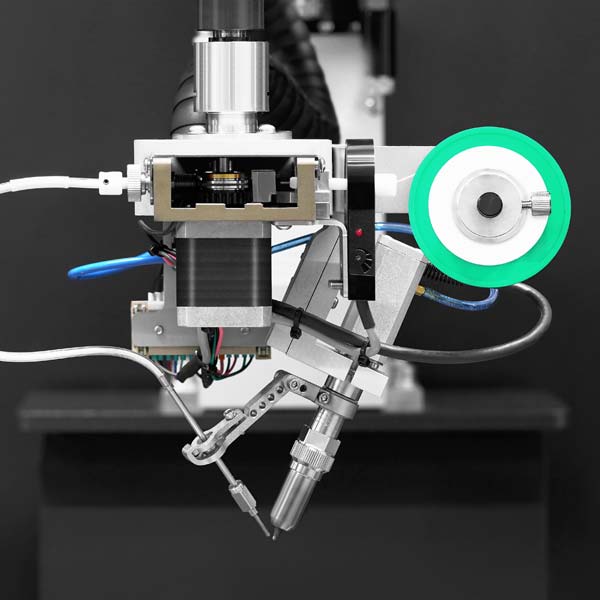

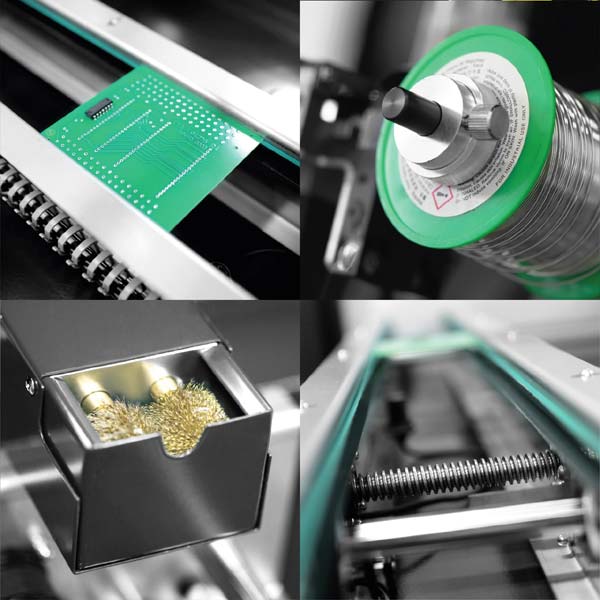

Looking at the electronics manufacturing industry, we can see this process at almost all stages. Continuously improved solder paste printers (like YAMAHA YSP20), pick & place machines (like YAMAHA YSM20), and reflow ovens (like HELLER 1707 MK5) have been standard in this industry for many years and today it is hard to find a company where the vast majority of production would not be automated. The process has been going beyond the SMT line for a relatively short time and there is a great interest in solutions that automate e.g. THT assembly. The market-leading solution for this purpose is the REECO Soldering Robot and on its example we can look at how the risk resulting from the human factor is minimized by automating a specific production stage.

With regard to the issues raised earlier and the very relevant issues of epidemiological protection, it is important to start from the obvious fact that a robot cannot get sick or be a carrier of disease. The robot does not get tired, does not need breaks, and its work is uniform throughout the day, week and month. Although it is obvious, the consequences are far-reaching and not always fully appreciated. The key factor here is repetition. A human being is able to perform the same tasks as a robot – but his work will never be as predictable and the process as uniform.

This comparison is well illustrated by the series of duels that took place at various trade fairs – among others the Polish Soldering Championship – RSC – between Polish and other countries’ Soldering Champions and REECO Soldering Robot. As the results statistics show, man can compete with the robot and keep the same or even higher speed of making 256 connections and even in many cases match it in the quality of execution – but he or she is only able to do it for about 5 minutes – 10 minutes. A robot, properly maintained, is able to do it all the time. This shows that the key aspect of automation is repeatability – keeping the same speed, precision and quality no matter how long or at what time of day or night the same tedious task is performed. This aspect translates into planning capabilities – production management is simpler and much more efficient, for example within the framework of component management, if we are able to determine precisely – up to a single piece – how many products or activities will be performed by the end of a day or month. In production based on human labour this is impossible.

This comparison is well illustrated by the series of duels that took place at various trade fairs – among others the Polish Soldering Championship – RSC – between Polish and other countries’ Soldering Champions and REECO Soldering Robot. As the results statistics show, man can compete with the robot and keep the same or even higher speed of making 256 connections and even in many cases match it in the quality of execution – but he or she is only able to do it for about 5 minutes – 10 minutes. A robot, properly maintained, is able to do it all the time. This shows that the key aspect of automation is repeatability – keeping the same speed, precision and quality no matter how long or at what time of day or night the same tedious task is performed. This aspect translates into planning capabilities – production management is simpler and much more efficient, for example within the framework of component management, if we are able to determine precisely – up to a single piece – how many products or activities will be performed by the end of a day or month. In production based on human labour this is impossible.

The REECO Soldering Robot is a device that can work in line with other equipment – whether it is a REECO screw assembly, dosing or labeling robot or other production line robots.

Of course, every production process, even one based on industrial robots, requires the participation of people – operators and service technicians, which means that the human factor is never completely eliminated, but the risk associated with it decreases with increasing levels of automation.

Advice on robotization and automation in Central and Eastern European countries, especially in this difficult period of crisis, is provided by the RENEX Group, as part of its mission to support the growth of its business partners. We invite all interested parties to contact RENEX Technical and Commercial Advisors. Find out more at https://www.renex.pl/ro/start/.

Advice on robotization and automation in Central and Eastern European countries, especially in this difficult period of crisis, is provided by the RENEX Group, as part of its mission to support the growth of its business partners. We invite all interested parties to contact RENEX Technical and Commercial Advisors. Find out more at https://www.renex.pl/ro/start/.

Contact:

Andrei Bratanov – National Sales Manager

Strada Văliug, nr. 32, Sector 1

13986 București, ROMÂNIA

T: +40 799 774 330

E: Andrei.Bratanov@renex.ro