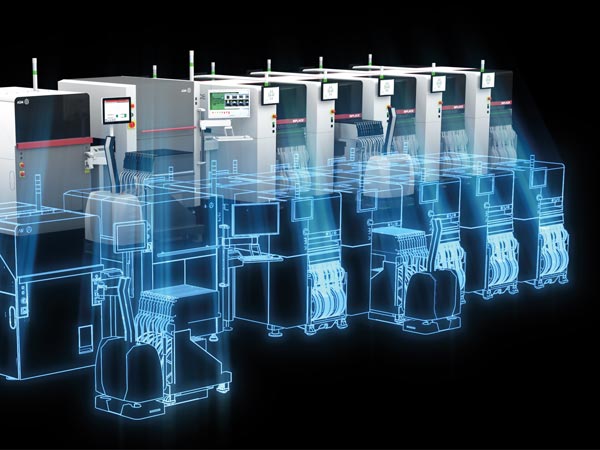

Open Automation – ASM’s modular, flexible and vendor-independent concept for the step-by-step and financially feasible automation of the electronics factory. — Image source: ASM

Since efficiency, productivity and resilience drive automation in SMT production, ASM presented at this year’s Productronica trade fair under the motto “Open Automation in the Integrated Smart Factory” a comprehensive, open and modular concept for seamless M2M communication and the integration of third-party solutions and existing systems based on open interfaces such as the Hermes standard and IPC-CFX. A practical example of this concept is presented on ASM’s Open Automation Line, which even features autonomous robots (AIVs) that supply materials and remove placement waste.

Optimal degree of automation

The high-precision and high-volume DEK TQ printer is predestined for implementing automation concepts because it can operate for up to 8 hours without a single user assist. — Image source: ASM

In ASM’s Open Automation concept, low-pad AIVs can replace changeover tables completely on their own. — Image source: ASM

The result of any transformation should be a factory that’s more cost-effective, efficient, and flexible while turning out higher-quality products. Looking at the degree of automation under the maxim of achieving the best possible return on investment, the “Pareto Principle” claims that 20 percent of the resources deployed will deliver 80 percent of the results. Any additional percentage point of improvement requires disproportionate expenditures and should therefore be considered with great care. From an ROI-centered perspective, a fully automated shop floor rarely delivers optimal results. With the modular Open Automation concept, electronics manufacturers can find the optimal degree of automation themselves while implementing it at the pace that best suits their specific requirements.

Open interfaces and protocols make it possible to load and unload PCBs on the line with automated AIVs and board handling equipment instead of human operators. — Image source: ASM

Existing lines and elements can be integrated into Open Automation regardless of their source, and processes can be automated step by step in order to achieve sustainable investment protection. In addition, the concept makes it possible to integrate future technologies such as autonomous process control and AI systems into your workflows with relatively little effort.

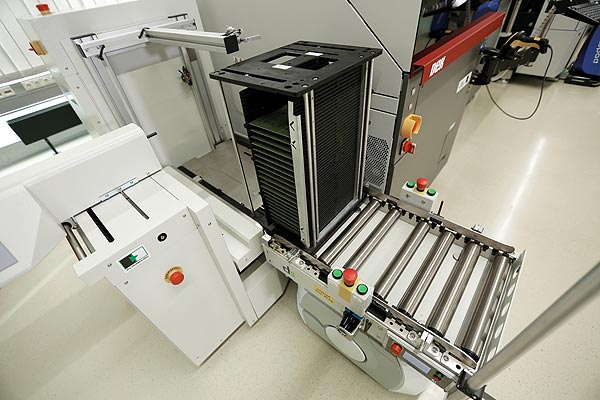

The automatic ASM Material Tower storage system supplies component reels in setup-optimized order in magazines for collection by AIVs. — Image source: ASM

The line which ASM presents at the Productronica to illustrate the practical application of Open Automation consists of the latest DEK printer, the ASM ProcessLens 5D inline SPI system, SIPLACE placement machines, an AOI system from Viscom, handling systems from Nutek, and software solutions from ASM and its sister company Critical Manufacturing. ASM will demonstrate various modular automation applications at its booth, including complete setup changeovers by replacing feeder tables with centrally controlled AIVs. The robots can switch out tables with no manual assists and return tables that are no longer needed to the setup area.

Mapping of automated material flow processes

Material flow processes will also be presented at the booth, including the automatic loading and unloading of boards and finished products with AIVs. For example, the SIPLACE placement machines may signal refill requirements to the ASM Material Manager, which then instructs an AIV to pick up components from the automated ASM Material Manager storage system that has already arranged the reels in a setup-optimized sequence. The mobile robot meets an operator at the line who has been notified of the pending refill process by ASM Command Center, the company’s smart operator management software. The special feature of this approach is that it is not limited to component reels but works equally well for things like board magazines, stencils, or solder paste. Even tasks like the disposal of waste can be automated with AIVs. Likewise, the transport between the main warehouse and other storage systems can be handled with autonomous transport robots to ensure the continuous supply of the production lines.

An intelligent SPI system like the ASM ProcessLens, which truly understands what it measures, is one of the key factors for successful SMT factory automation. — Image source: ASM

ASM’s automated waste disposal system relieves employees of the time-consuming collection and disposal of waste being generated by the placement process. — Image source: ASM

The printing process on the line is controlled by the self-learning ASM ProcessExpert system with optional autonomous optimization. The system continuously monitors and processes the data generated during the placement process in order to run trend analyses that make it possible to optimize the component pickup rates. In addition, AOI data from any third-party system can be integrated into the ASM ProcessExpert via IPC-CFX. This enables the fast and detailed data correlation of all process steps along the entire line, broken down to a single pad, for comprehensive root cause analyses in the rare case that faults occur.