Electronic components are becoming smaller and more complex. Miniaturisation brings with it complexities when protecting sensitive assemblies from external influences. Altus a leading distributor of capital equipment for the electronics assembly industry in the UK and Ireland, is addressing this concern with the help of its pre-eminent supplier, Rehm Thermal Systems.

Electronic components are becoming smaller and more complex. Miniaturisation brings with it complexities when protecting sensitive assemblies from external influences. Altus a leading distributor of capital equipment for the electronics assembly industry in the UK and Ireland, is addressing this concern with the help of its pre-eminent supplier, Rehm Thermal Systems.

As components reduce in size, the risk of contamination like dust and moisture can have a detrimental effect on its ability to work effectively. In order to protect electronic assemblies, encapsulation is an important step in preserving the delicate parts from outside elements and mechanical stress.

As components reduce in size, the risk of contamination like dust and moisture can have a detrimental effect on its ability to work effectively. In order to protect electronic assemblies, encapsulation is an important step in preserving the delicate parts from outside elements and mechanical stress.

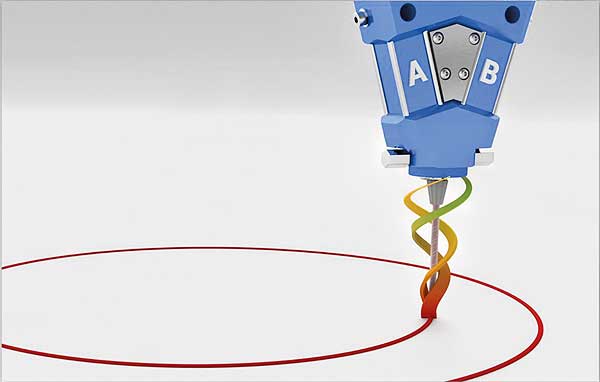

Rehm has created a lacquering system, ProtectoXP, which includes the option of 2K encapsulation for very high levels of protection. The new Protecto coating system was developed to satisfy demands for the highest quality, stability and productivity for automatic in-line coating tasks. There was particular emphasis placed on maintainability, intuitive programme configuration and ultra-flexible equipment that can be adapted to customer requirements. The new 2K encapsulation does just that.

“As electronic components become more elaborate and complex, discovering problems due to external influences would have a huge effect on the manufacturing process, delaying the process by having to clean or re-make parts,” explains Matthew Jones, Altus Sales Director.

“It is important for manufacturers to know the parts being manufactured are in good working order and are protected from any possible contamination. ProtectoXP is answering this requirement by protecting individual components or entire assemblies from corrosion, moisture or vibration, with a protective lacquer which can be applied after soldering.

“Since Altus has offered this innovative system to customers we have received much interest as manufacturers look for cost-effective options to protect sensitive assemblies.”

The Protecto lacquering systems have multifunctional lacquer applicator units that can apply the lacquer by spraying, dispensing or jet, to suit the application. The ProtectoXP has a wide range of applicators available, through which it is possible to select the right equipment for the corresponding application. From these applicators up to four can be used simultaneously, for example the 2K system.

In this volumetric dosing system, two different material components – irrespective of whether they are high or low in viscosity – are applied uniformly and without pulsation, and independently of any fluctuations in pressure, temperature or viscosity. A 2K encapsulation of this kind is always used when a particularly high level of protection is required. The volumetric operating principle of the applicators ensures that the correct quantity of material in the correct mixing ratio is delivered every time, irrespective of temperature or fluctuations in pressure.

Altus Group | www.altusgroup.co.uk