Since adding the Rehm VisionXP+ convection soldering system to its portfolio, Altus Group, a leading supplier of capital equipment in the UK and Ireland, has seen significant interest in the high-performance equipment, particularly because of its stable reflow soldering process.

Since adding the Rehm VisionXP+ convection soldering system to its portfolio, Altus Group, a leading supplier of capital equipment in the UK and Ireland, has seen significant interest in the high-performance equipment, particularly because of its stable reflow soldering process.

VisionXP+ convection soldering system represents the highest in quality and flexibility with an outstanding throughput rate. With new updates and developments continually made to the product, it can effectively ensure optimum heat transfer for different requirements.

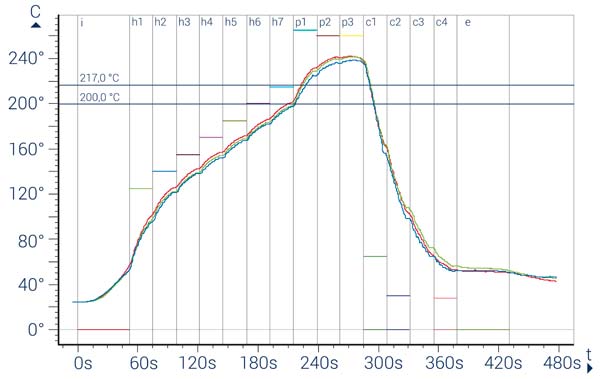

Richard Booth, CEO- Altus Group said: “Rehm VisionXP+ is one of the most technically advanced soldering systems on the market and we are extremely pleased to be able to offer the equipment to our customers. One of the features that makes this system a game changer is its separate heating zones and reproducible temperature profile. This is the basis for the best soldering results as electronic components with different requirements and profiles can be produced with ease.

“As electronics become more complex, it is important to have soldering processes which can be adapted to achieve solder joints with fewer voids. Thanks to the optimum heat transfer properties of the VisionXP+, problem-free and reproducible profiling is achieved. This includes saddle profile or linear profile which help to attain the best soldering results.“

The saddle or linear profile is generally selected on the basis of the solder paste being used. With a saddle profile, the assembly is first brought to the desired temperature in the pre-heating area. Once the saddle temperature is reached, the paste is activated and the temperatures of the different thermal masses of the assembly are aligned. Soldering then takes place in the short peak range of the furnace.

With a linear profile, the assembly is not stepped during soldering, but is heated with exactly the same linear temperature increase. Linear profiles may lead to the cycle time becoming shorter and to the minimisation of soldering errors, such as tombstoning.

A further important feature of VisionXP+ is its nozzle hole fields with a special geometry to ensure an even flow onto the assemblies. The temperature and the flow speeds of the upper and lower heating zones are individually adjustable therefore allowing the assembly to be heated fully and evenly.

Because of the variable transport speed, the optimum profiling setting at which smaller components do not overheat and larger components are still heated sufficiently to ensure reliable soldering can be competed.