Buses and trams of the Walloon Regional Transport Company SRWT/TEC will be equipped with the “VENTURO” uniform transport management platform from Kontron.

To equip approximately 2,500 buses and LRTs (Light Rail Transit vehicles) utilizing distributed heterogeneous embedded systems, the Belgian Walloon Regional Transport Company called SRWT/TEC looked for a new unified In-vehicle management platform. The goal was to unify the system topography and to integrate the various systems into a single, centralized and open embedded platform. In addition to reducing maintenance and upkeep costs, the SRWT/TEC wanted to standardize the different data exchange interfaces between vehicles, control center and the traffic facilities. At the end of 2008, the SRWT/TEC entrusted the joint venture of Kontron and Fabricom GTI with the development and production of the vehicle management platforms after which the installation in the vehicles began.

Buses and trains in public transport are increasingly using more electronic communication systems to make fleets more economical, reliable and also to give passengers more comfort and service. But an increasing number of out-dated devices are working against the cost efficiency target.

A variety of individual subsystems leads to an increased burden of repairs. In addition, a non-uniform device structure can cause massive problems with the public transport’s comprehensive data acquisition and control network operating with different functions and various data structures.

These were the challenges presented to the SRWT and its five regional transport operators (TECs).

Up until now, in their approximately 2,500 buses and trams, a board computer with an associated driver display console was used for ticketing. Additionally, a second computer was installed in each driver cabin for route control and communication purposes, which also controlled the passenger information display, stop-station announcement and connection line information. Due to the five separate transport divisions, one for each region of Wallonia, not just one but several systems with the same functionality were used. This also made operation unnecessarily complicated for the driver, because within every bus or line change a different infrastructure could be found.

To unify the various equipment and achieve better cost-efficiency, the SRWT/ TEC decided to equip the entire vehicle fleet with a new, unified vehicle management system. This new system would be based on one single board computer, therefore centralizing all the computing tasks for ticketing, passenger information and announcements, location identification, data acquisition, vehicle (via CAN-Bus), system diagnostics, and internal / external communications management.

Furthermore, to increase availability while lowering the maintenance costs of the vehicles, the shortest possible Mean-Time-To-Repair (MTTR) was required. Moreover, openness to the implementation of future functionalities was also called for, such as rear view camera, indoor video surveillance, networking with mobile equipment or people counting systems.

Wanted: One for all

In the announcement phase, SRWT/TEC examined different proposed system solutions. Most of these solutions, however, did not offer all the required functionalities. Others argued for distributed computing systems that led to high hardware implementation while currently lacking possible hardware consolidation.

Overall, these solutions involved additional costs and maintenance. Therefore the decision was between solutions leading to extensive adjustments or solutions offering open custom designs, tailored to meet current needs and open for future ones, as presented by Kontron with its embedded computing platforms. Kontron was already known by SRWT/TEC as an experienced supplier for the transportation market. Additionally, because of extensive ODM services for custom system development, Kontron was in a position to not only develop and produce the board computer, but also the peripherals such as the driver console and RFID badge readers, and therefore took over the responsibility for the entire hardware platform. For SRWT/TEC this was a very efficient combination; one supplier to handle the custom system design and manufacture all components including the computing core. This drastically reduced the efforts of the supplier management allowing SRWT/TEC to fully concentrate on its essential tasks.

Direct contact to the engineers

An essential advantage for the engineers at SRWT/TEC was the fact that they could speak directly with Kontron’s developers and quickly get substantial answers to all the requirements and questions, such as those concerning an optimized system design for shortest Mean-Time-To-Repair (MTTR). TEC/SRWT was able to undertake the programming of application software for the new systems thanks to evaluation boards that Kontron was able to provide which functionally represented the management system at an early phase in the project. Because of this efficient work flow, the “Venturo” systems were announced in 2010. The integration of the management system into the vehicles will be handled by the joint venture partner Fabricom-GTI in the respective TEC depots.

The central board computer “Venturo CBox”

The heart of the Venturo vehicle management platform is the EN50155-compliant Venturo CBox central board computer, which is based on Intel® Atom™ ×86 architecture. Compared to dedicated RISC designs, the ×86 technology enables improved graphics, more performance and more complex connectivity; a significant advantage, since the management system will be networked via serial and Ethernet interfaces as well as WLAN and 3G GSM. Additionally, the ×86 architecture provides a higher software compatibility with the IT systems in the control center and, thanks to the general-purpose design of ×86 technologies, the system is open to future tasks such as video surveillance and digital signage.

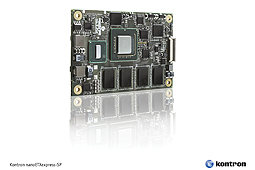

For the system design, the credit card-sized COM Express™ compatible Kontron Computer-on-Module nanoETXexpress-SP was chosen because of its extremely energy-efficient Intel® Atom™ processor. Computer-on-Modules integrate the computing core components such as processor, chipset and standard PC interfaces into a pluggable and performance-scalable module. The integration of additional system components, and the implementation of application-specific interfaces, is handled via a custom designed carrier board. To keep the size of the board computer as compact as possible, two superimposed boards are used. The upper carrier board integrates the Kontron nanoETX express-SP, a 4× Ethernet switch and an optional 2.5-inch SATA automotive hard disk or SSD. The lower board integrates the 3G GSM for wireless communication via HSxPA, UMTS, GPRS and EDGE, the WiFi module for wireless networking with IEE 802.11/a/b/g WLANs and a GPS module with gyroscope and odometer interface for dead reckoning.

With this, the board computer centralizes all the necessary components and interfaces in a single, fanless, rugged aluminum IP54 protected housing in the new vehicle management system designed to work in extended temperature ranges as required in buses.

The interfaces of the board computer are ergonomically designed. The three connectors for WLAN, GPS and GSM antennas are placed on the opposite side of the housing from where all the other connectors are located, allowing for orderly cabling. A rugged, 90 pin, IP68 protected automotive connector handles all I/Os (CAN-Bus, 12 × EN50155 compliant RSxxx 12×, 4 × RS232, and 12 EN50155-compliant digital I/Os) as well as the power supply. Fast Ethernet channels can be connected over four M12 connectors and a 50-pin DSUB connector binds all communication signals and the power supply to the driver’s console via a single cable of up to 15 meters in length. This concept reduces the number of interface connectors accelerating both the removal and the installation of the systems and therefore reducing maintenance times. However, with a MTBF of 80,000 hours in a temperature range from -25°C to +70°C, this should only rarely be necessary.

The GSM Voice & Audio Box “Venturo GBox”

Deliberately designed as an independent system, the GSM voice and audio box Venturo GBox combines emergency call functionality with an integrated audio switch. It can be placed anywhere near the audio sources to minimize the amount of wiring. Independent from the board computer, the audio box takes over key security functions. Activation of one of the two connected emergency switches automatically initiates a voice connection via an integrated GSM module.

As an example, in case of an emergency, a voice connection can be directly routed between the passenger compartment or the driver’s cabin and the control center (depot) while an SMS is automatically sent containing the precise location data to ensure help will be quickly dispatched.

For these fundamental security options, as well as the programmable switching tables for five different audio sources on three audio outputs including one amplified output, the Venturo GBox offers embedded JAVA™ processing based on a state-of-the-art ARM 9 processor architecture.

This enables the use of the GSM Voice & Audio Box as a standalone device, independent from any board computer, enabling highest reliability with no single point of failure. The Venturo GBox features the same intelligent cabling with one SMA connector for the antenna and one rugged automotive IP68 rectangular male connector with 56 pins on the opposite side of the IP 54 protected housing.

The fanless Venturo GBox also complies with EN50155 requirements.

The peripherals

Kontron not only developed and produced the central computing system and the GSM Voice & Audio Box, but also developed the necessary peripheral components such as the driver’s console and the RFID badge reader. The driver’s console with an 8.4-inch touch screen is the central HMI of the complete management system. As an option, a ticket printer and a two-line fluorescent display for customer information, such as a fare, can be integrated into the driver’s console, each one being centrally controlled by the board computer via serial RS-422 interfaces (American EAI-422). Since the Kontron management system consistently uses common interface standards, alternative driver consoles from other manufacturers can also be used.

The RFID badge reader allows two ISO 14443A/B compliant RFID cards (e.g., Mifare® DESFIRE) to be simultaneously read / updated.

Additionally it allows these two cards to be permanently and securely inserted without any risk of destruction and risk of jump-off due to shocks and vibrations during operation of the vehicles. It is used for driver identification/authorization and for the controller identification/authorization as well.

Conclusion

With the new “Venturo” vehicle management platform, the SRWT/TEC now has a consistent, reliable and maintenance-friendly solution for the entire vehicle fleet. Thanks to the unified hardware base, both the tariff information as well as the application software can automatically be updated, enabling a much more efficient work process. Thanks to Kontron’s established expertise in the Transportation segment and the extensive services provided, the SRWT/TEC could concentrate on the development of the application software and integration into the operations control system, reducing time to deployment.

The rugged, EN50155 compliant, fanless design, the use of common standards and the high flexibility make the Venturo vehicle management system the ideal solution for nearly every transportation requirement.

Economical over the entire life cycle

Thanks to the Computer-on-Modules approach, the board computer offers efficient scalability throughout the entire product life cycle.

Simply by changing the Computer-on-Module, additional performance needs can be met years later. In addition, the modular design reduces the cost of repairs: Unlike a single-board solution, in case of a defect, not all components need to be replaced, but just the affected component.

Contact:

Andrea Mayer

Andrea.Mayer@kontron.com

Product Marketing Manager

Kontron Modular Computers GmbH

Sudetenstraße 7

87600 Kaufbeuren, Germany

Tel: +49 8341/803-428 begin_of_the_skype_highlighting +49 8341/803-428 end_of_the_skype_highlighting begin_of_the_skype_highlighting +49 8341/803-428 end_of_the_skype_highlighting