The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, is introducing THERM-A-GAP™ PAD 80LO, a high-performance thermal gap pad with low oil-bleed and migration characteristics. Ideal for use where the appearance or production issues of silicone oils are undesirable, the new thermal gap pad is a highly reliable and long-term solution for any type of mission-critical or high-performance electronic system.

The Chomerics Division of Parker Hannifin Corporation, the global leader in motion and control technologies, is introducing THERM-A-GAP™ PAD 80LO, a high-performance thermal gap pad with low oil-bleed and migration characteristics. Ideal for use where the appearance or production issues of silicone oils are undesirable, the new thermal gap pad is a highly reliable and long-term solution for any type of mission-critical or high-performance electronic system.

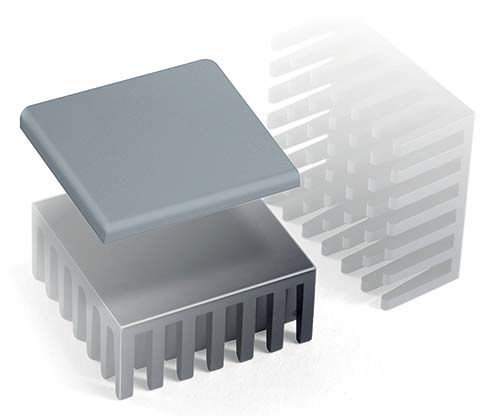

With a typical thermal conductivity of 8.0 W/m-K according to the ASTM D5470 test method, THERM-A-GAP™ PAD 80LO is a compressible thermal elastomer for conducting heat in gaps between a heat-generating surface like a semiconductor or battery and a heat-dissipating surface.

Offering a hardness of 60 Shore 00 (ASTM D2240), the product exhibits high levels of stress relaxation, with a nearly 90% reduction in compression force after just one hour. Parker Chomerics designed THERM-A-GAP™ PAD 80LO to minimise stress on components like integrated circuits and also provide physical protection such as vibration dampening, while maintaining effective thermal contact wherever gap conformability or rough surface texture is a concern.

Applications set to benefit include GPUs, CPUs, memory modules and other high-performance computing equipment, as well as 5G and telecommunications systems. Automotive sensors and devices, battery and energy storage modules, and defence electronics can also gain from the attributes of THERM-A-GAP™ PAD 80LO.

Applications set to benefit include GPUs, CPUs, memory modules and other high-performance computing equipment, as well as 5G and telecommunications systems. Automotive sensors and devices, battery and energy storage modules, and defence electronics can also gain from the attributes of THERM-A-GAP™ PAD 80LO.

The new RoHS-compliant thermal gap pad features a high-tack surface that reduces contact resistance, an operating temperature of -50 to 200°C and UL 94 V-0 flammability rating. THERM-A-GAP™ PAD 80LO is also electrically isolating. Electrical properties include: 8 kVac/mm dielectric strength (ASTM D149); 1013 Ωcm volume resistivity (ASTM D257); 0.05 dielectric constant at 1,000 kHz/2.0 mm thick (ASTM D150); and 0.05 dissipation factor at 1,000 kHz/2.0 mm thick (Chomerics test method).

Parker Chomerics can provide THERM-A-GAP™ PAD 80LO in sheets or perform die-cutting to custom sizes (width and length) in thicknesses from 1.0 to 5.0 mm.

Learn more about THERM-A-GAP™ PAD 80LO here.

Chomerics

PARKER HANNIFIN CORPORATION